Detachable surface glass type touch screen and preparation process

A surface glass, touch screen technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problems of waste of resources, high price, glass breakage, etc., to achieve simple replacement and easy replacement. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe in detail the technical content of the present invention and its advantages compared with traditional touch screens, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

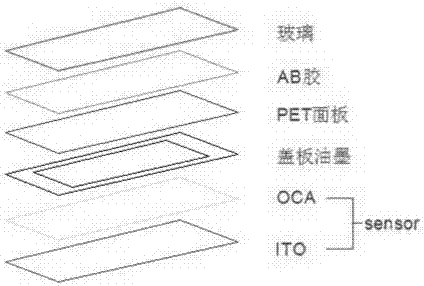

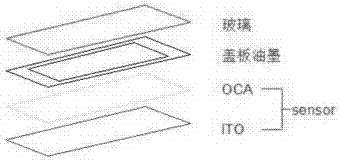

[0024] Such as figure 1 As shown, a detachable surface glass touch screen includes surface glass, PET panel, cover ink and sensor, the surface glass and PET panel are bonded together by AB glue, and the OCA surface of the surface glass and AB glue Bonding, the PET panel is silk-screened with cover ink with a silk-screen effect, the non-ink surface of the PET panel is attached to the silicone surface of the AB glue, the ink surface of the PET panel is connected to the OCA of the sensor function sheet face fit.

[0025] Wherein, the surface glass is deep chemically strengthened glass, the strength is 130g*30cm falling ball center point three times, the surface hardness is 6H and above, the strengthening depth is 10-12um, the stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com