A dual-band thin-film photodetector and its preparation method

A photodetector and dual-band technology, which is applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of limited detection band and limited response rate of photodetectors, so as to improve device responsivity, Simple preparation process and good light absorption properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

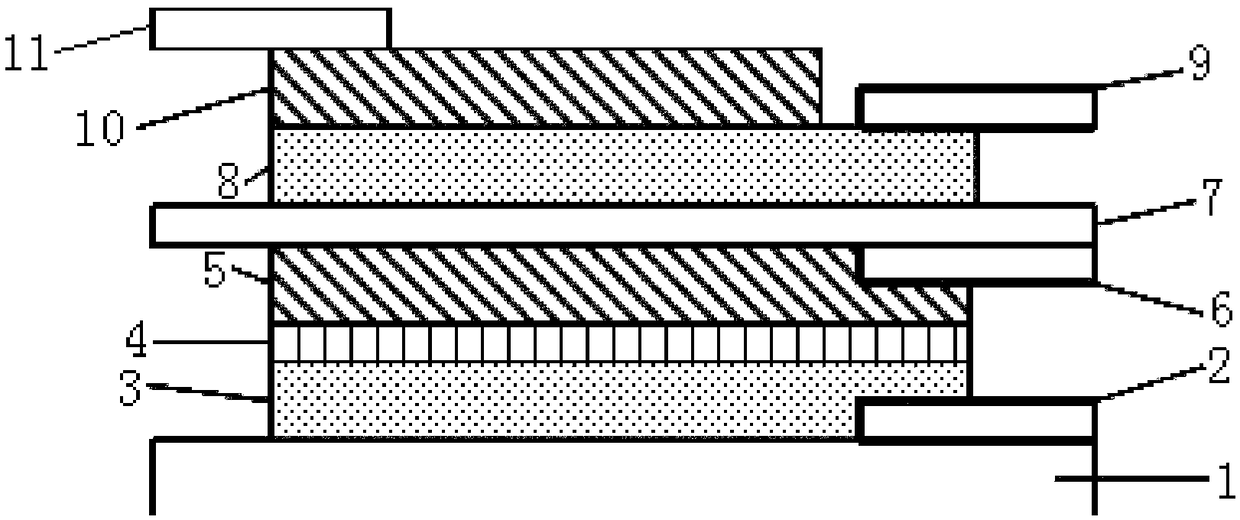

[0044]1) Select silicon wafer, glass or PET plastic as the base sheet 1, clean it, spin-coat photoresist on its surface, and pass photolithography process, figure 1 The photoresist at the position of the middle electrode is washed away after exposure to form grooves.

[0045] 2) Depositing the first electrode layer 2 on the surface of the sample by electron beam evaporation process, the thickness of which is 10 nm.

[0046] 3) Soak the above sample with acetone to remove the remaining photoresist.

[0047] 4) adopt chemical vapor deposition method to prepare graphene thin film on a copper foil, it can be monolayer or several layers, and transfer to the surface of the first electrode layer 2 of step (2) gained; Wherein the transfer method of graphene thin film For: uniformly coating a layer of polymethyl methacrylate film on the surface of the graphene film, then putting it into an etching solution for 4 hours to etch and remove the copper foil, leaving a graphene film support...

Embodiment 2

[0063] 1) Select silicon wafer, glass or PET plastic as the base sheet 1, clean it, spin-coat photoresist on its surface, and pass photolithography process, figure 1 The photoresist at the position of the middle electrode is washed away after exposure to form grooves.

[0064] 2) Depositing the first electrode layer 2 on the surface of the sample by electron beam evaporation process, the thickness of which is 100 nm.

[0065] 3) Soak the above sample with acetone to remove the remaining photoresist.

[0066] 4) adopt chemical vapor deposition method to prepare graphene thin film on a copper foil, it can be monolayer or several layers, and transfer to the surface of the first electrode layer 2 of step (2) gained; Wherein the transfer method of graphene thin film For: the surface of the graphene film is uniformly coated with a layer of polymethyl methacrylate film, then put into an etching solution for 5h to etch and remove the copper foil, leaving a graphene film supported by ...

Embodiment 3

[0082] 1) Select silicon wafer, glass or PET plastic as the base sheet 1, clean it, spin-coat photoresist on its surface, and pass photolithography process, figure 1 The photoresist at the position of the middle electrode is washed away after exposure to form grooves.

[0083] 2) Depositing the first electrode layer 2 on the surface of the sample by electron beam evaporation process, the thickness of which is 200nm.

[0084] 3) Soak the above sample with acetone to remove the remaining photoresist.

[0085] 4) adopt chemical vapor deposition method to prepare graphene thin film on a copper foil, it can be monolayer or several layers, and transfer to the surface of the first electrode layer 2 of step (2) gained; Wherein the transfer method of graphene thin film For: the surface of the graphene film is uniformly coated with a layer of polymethyl methacrylate film, and then put into an etching solution for 4.5h to remove the copper foil by corrosion, leaving a graphene film supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com