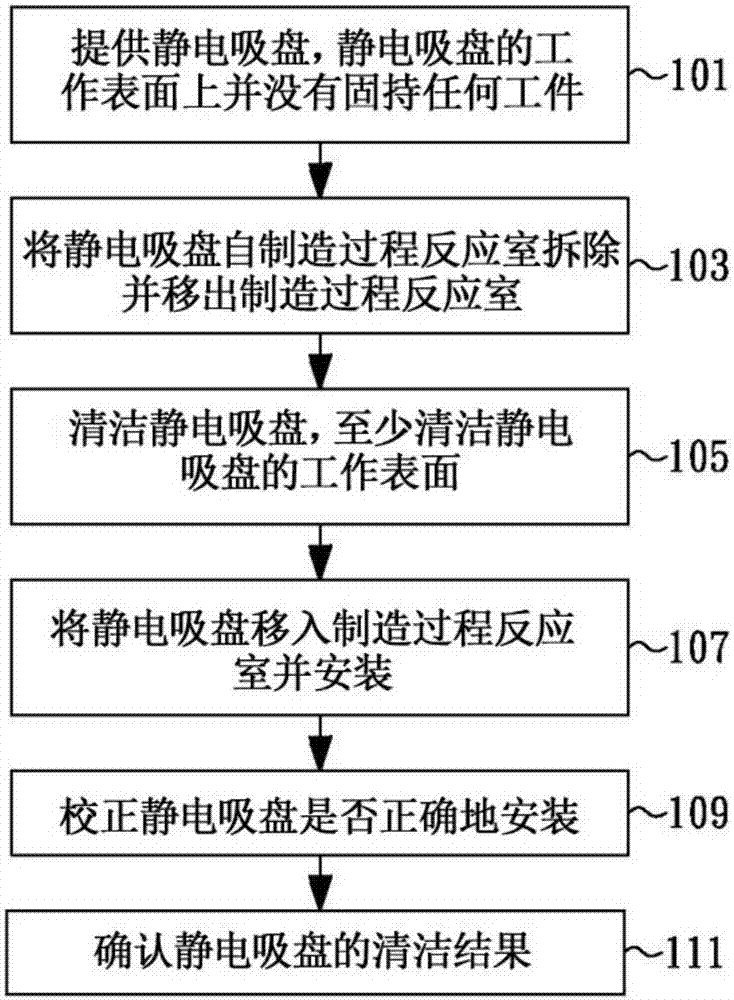

Method of cleaning electrostatic chuck

An electrostatic chuck and cleaning technology, applied in cleaning methods and utensils, holding devices using electrostatic attraction, cleaning flexible objects, etc., can solve the problems of pollution, time-consuming, increased cost, etc., to simplify maintenance procedures, save downtime and dismantling and the effect of the timing of reloading the correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A detailed description of the present invention will be discussed by means of the following examples, which are not intended to limit the scope of the present invention, but may be applicable in other applications. The illustrations reveal some details, it being understood that the details disclosed may differ from those disclosed, except in the case of expressly limited characteristics.

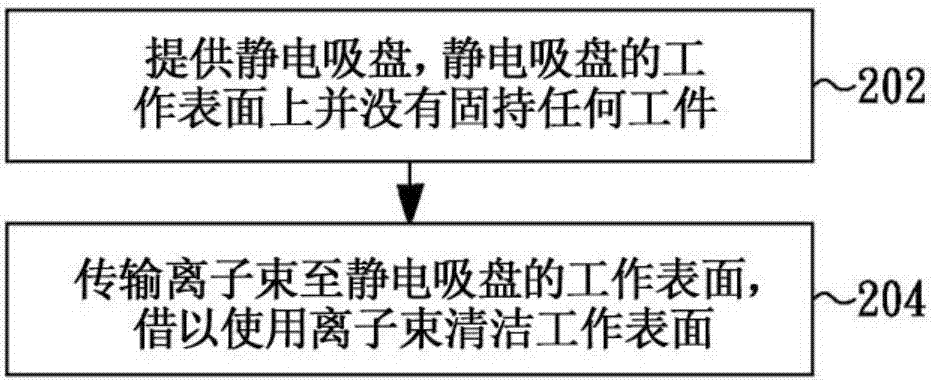

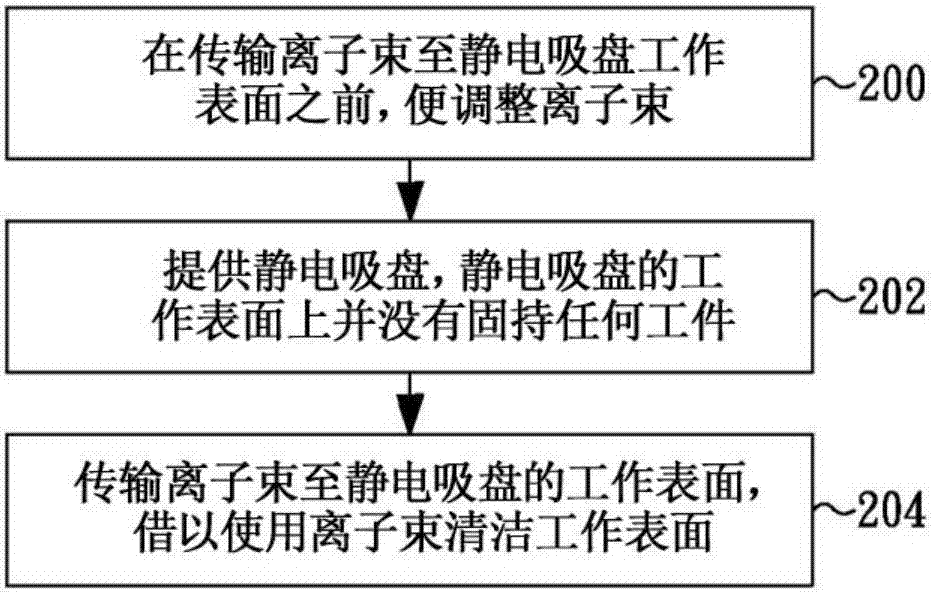

[0020] The starting point of the present invention is to clean the electrostatic chuck without moving the electrostatic chuck out and into the reaction chamber of the manufacturing process, so as to avoid several disadvantages that cannot be avoided by the conventional methods for cleaning the electrostatic chuck. In particular, since only contamination such as deposits occurring on the work surface on which the electrostatic chuck holds the workpiece affects the holding force between the electrostatic chuck and the work, only the work surface may be cleaned.

[0021] The basic concep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com