Process and device for processing product surface by utilizing laser

A laser processing and product technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of easy peeling of the skin, single color of the surface of the faucet, and poor corrosion resistance, so as to improve the neatness of the appearance lines and save time and manpower and material resources, and the effect of reducing surface treatment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A process for laser treating the surface of a product, comprising the following steps:

[0051] 1) Fix the product to be processed; the product to be processed can be fixed by using a chuck or a three-jaw plate or other structural devices to avoid movement of the product to be processed when the surface of the product to be processed is processed by laser.

[0052] 2) Import the three-dimensional image of the product to be processed into the laser marking machine for programming according to the format of the marking machine; it is convenient to facilitate the operation of laser processing the surface of the product to be processed in the subsequent steps.

[0053] 3) Set the parameters of the laser marking machine; preset the power, frequency, speed and other parameters of the laser marking machine according to the requirements. During this process, the parameters of the laser marking machine can be adjusted many times, so that the products to be processed The pattern,...

Embodiment 2

[0059] A process for laser treating the surface of a product, comprising the following steps:

[0060] 1) Fix the product to be processed;

[0061] 2) Import the three-dimensional drawing of the product to be processed into the laser marking machine according to the marking machine format for programming;

[0062] 3) Set the parameters of the laser marking machine;

[0063] 4) Carry out laser marking on the surface of the product to be processed.

[0064] Electroplating is carried out on the surface of the product to be processed before step 1).

[0065] Before step 4), the surface of the product to be processed does not need to be marked with a sticker.

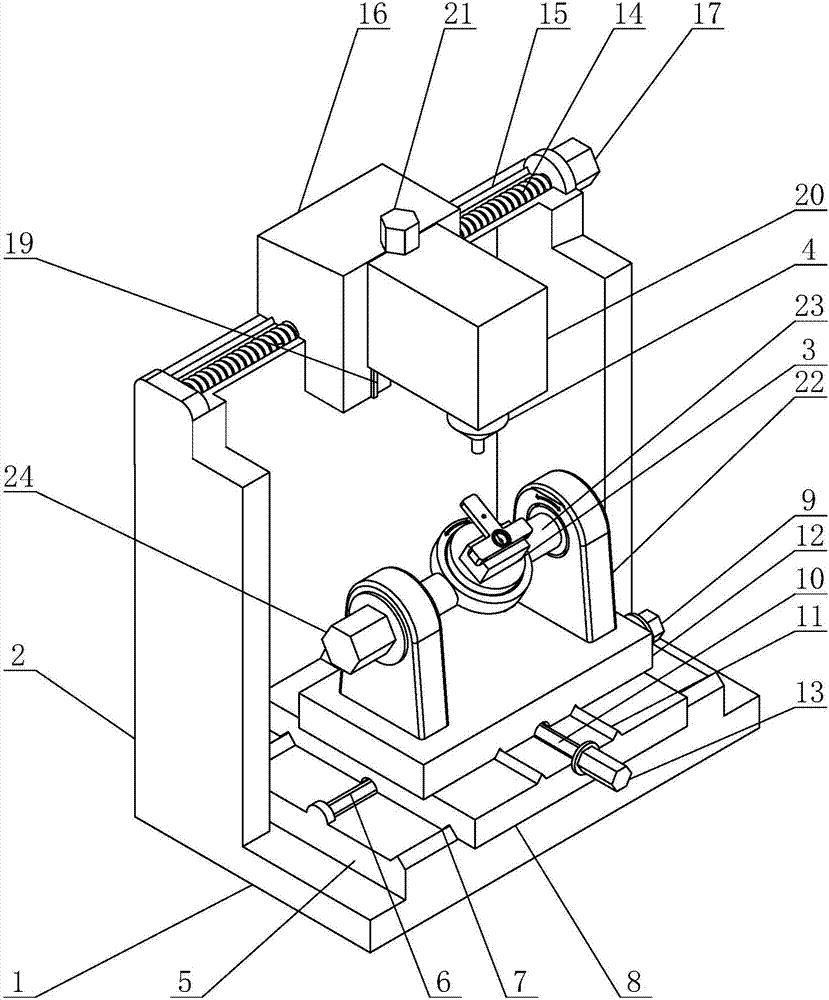

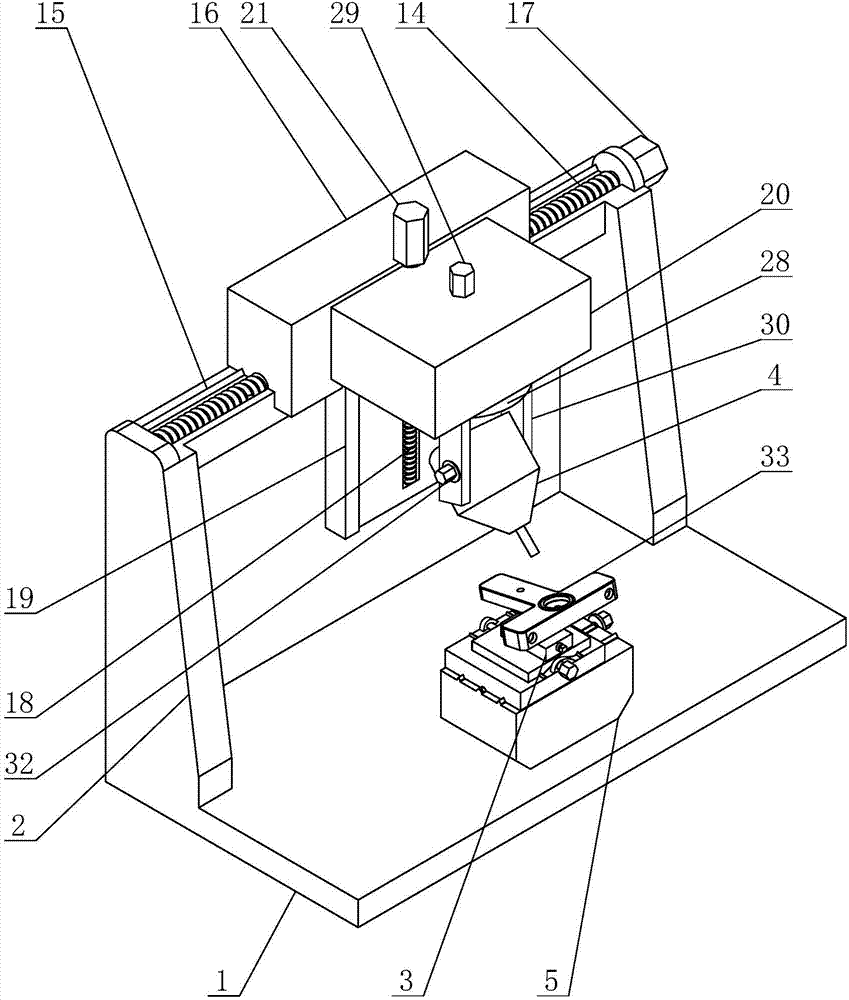

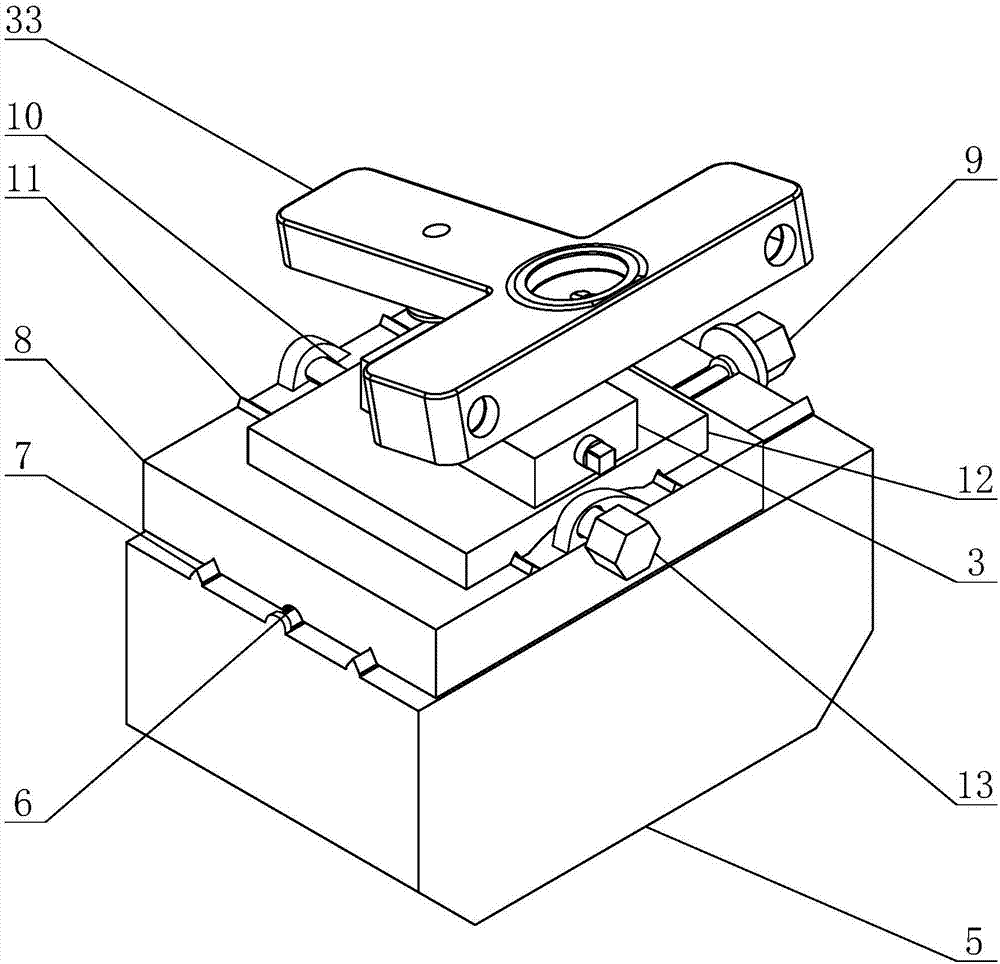

[0066] A device for laser processing product surfaces, comprising a base 1 and a gantry 2 vertically installed on the base 1, the base 1 is provided with a first power mechanism, and the gantry 2 is provided with a second power mechanism. The first power mechanism includes an X1 axis group and a Y1 axis group, and the X1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com