Automobile wire harness assembly table

A technology for automotive wiring harnesses and assembly tables, which is applied to wire tensioning appliances and manufacturing tools, can solve problems such as low efficiency, error-prone, and many forks, and achieve the effects of improving processing efficiency and avoiding manual measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

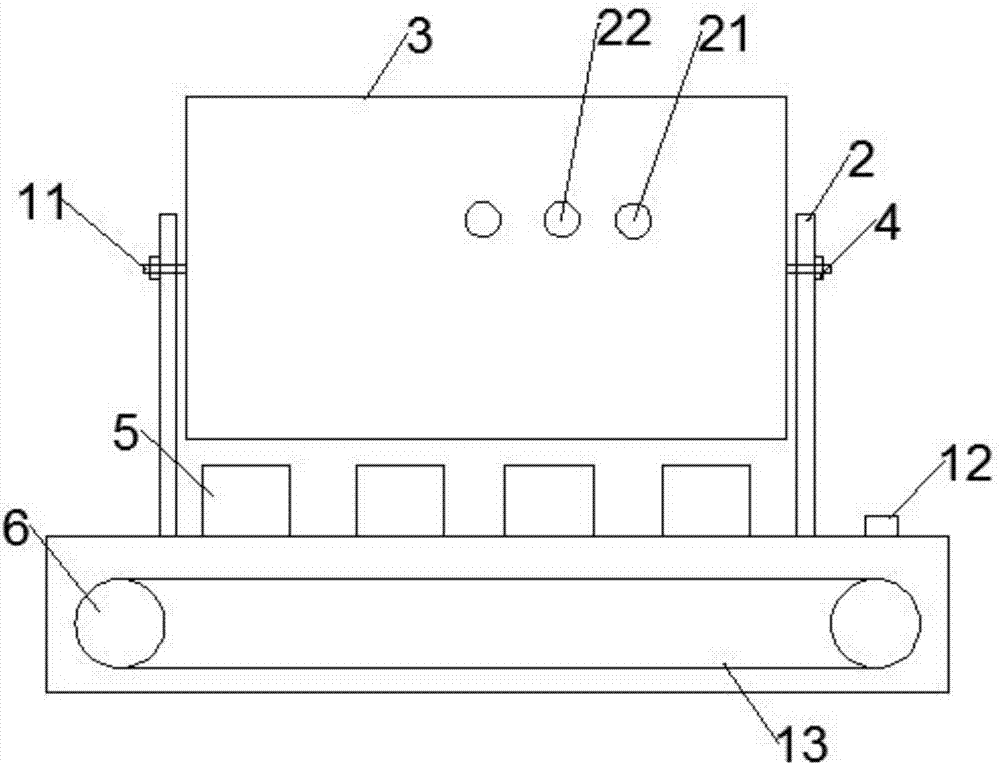

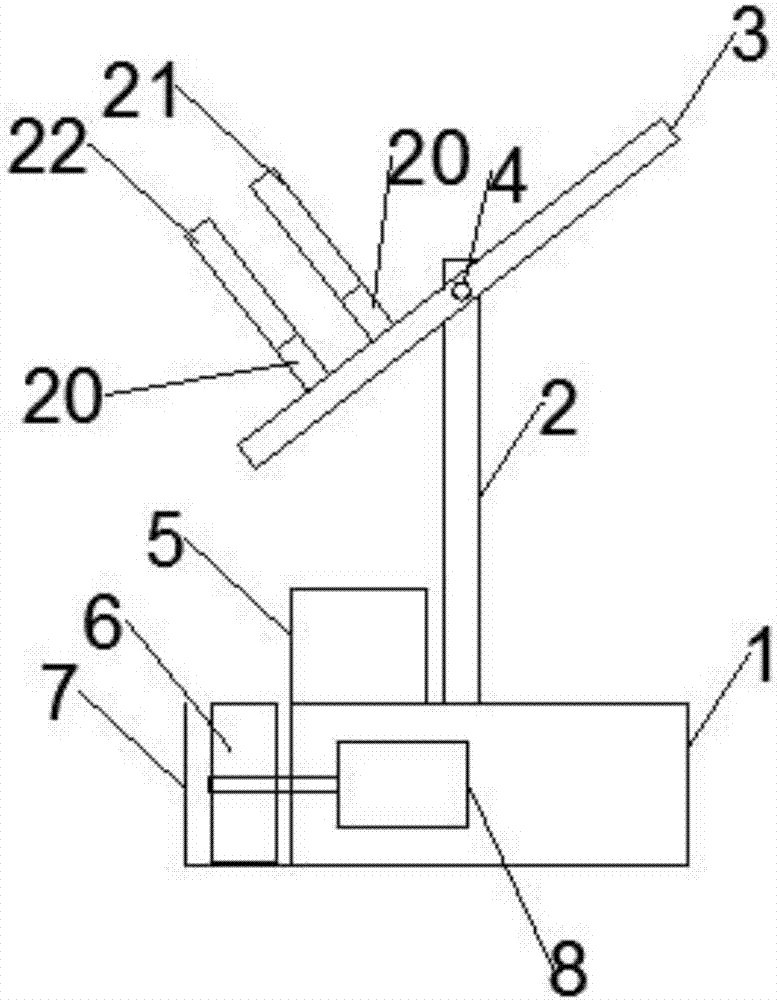

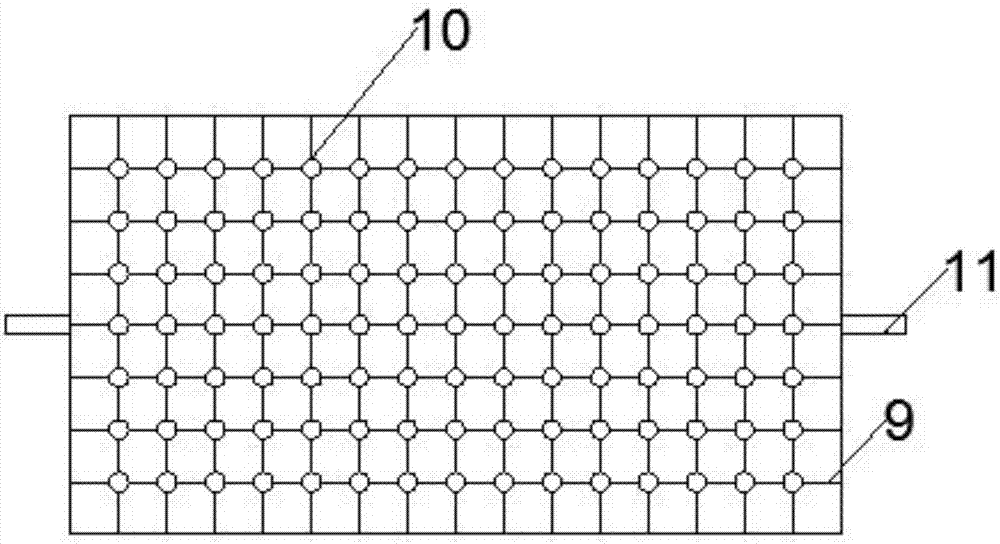

[0018] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 The specific embodiment of the present invention is shown: an automobile wiring harness assembly platform, including a base 1, a motor 8 is provided inside the base 1, a roller 6 is sleeved on the main shaft of the motor 8, and a conveyor belt 13 is sleeved on the outside of the roller 6 , the base 1 is provided with a control switch 12 for controlling the motor 8, the base 1 is provided with a plurality of tool boxes 5 and two poles 2, a panel 3 is arranged between the poles 2, and the panel 3 The surface is provided with a crossed scale line 9, the intersection point of the scale line 9 is provided with an internally threaded hole 10, and the two sides of the panel 3 are provided with externally threaded connecting rods 11, and the connecting rod 11 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com