Calcium hardness detector and calcium hardness detection method

A detector and hard detection technology, applied in the preparation of test samples, chemical analysis by titration, etc., can solve problems such as affecting detection accuracy and poor detection consistency, and achieve the goal of improving detection accuracy, avoiding errors, and improving measuring range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

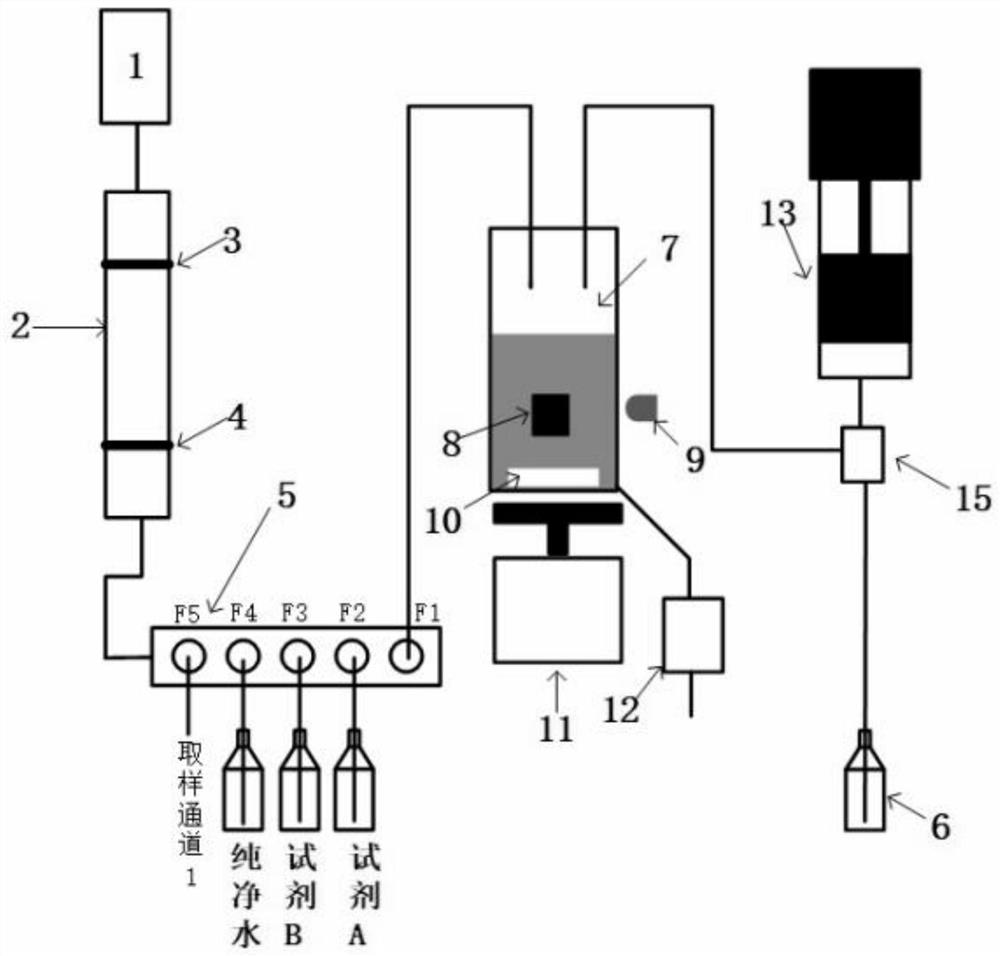

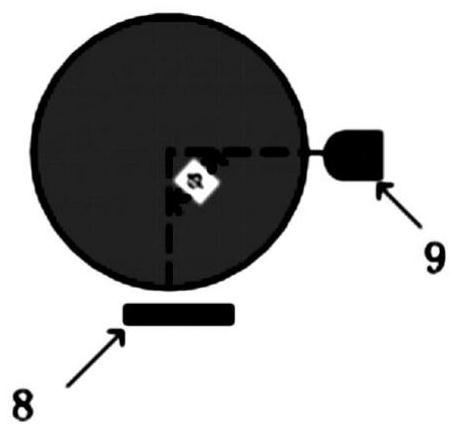

[0037] This embodiment provides a calcium hardness detector, such as Figure 1~2 as shown,

[0038] Including sampling tank, communication device, titration tank, dripping mechanism, reagent supply device and controller; reagent supply device is used to contain the reagents required for detection; sampling tank is used to obtain and output liquid, and can measure the dose of liquid; titration The tank is connected with the dripping mechanism, and the dripping mechanism is used to drip titrant into the titration tank. A titration monitoring device is arranged outside the titration tank. The titration monitoring device is used to monitor the reaction degree of the solution in the titration tank. The monitoring device includes a light source and a light sensing device. The light sensing device is not directly irradiated by the light of the light source; the communication device is connected with the sampling tank, titration tank and reagent supply device; the controller is electr...

Embodiment 2

[0049] The present embodiment is a method for detecting calcium hardness, which can detect the concentration of the first concentration solution;

[0050] Step 1: Instrument Calibration Process

[0051] 1. Cleaning with pure water:

[0052] 1. Take pure water to the titration tank 7: the control system first controls the power pump 1 to start pumping, and then the control system controls the F4 valve of the multi-position valve 5 to open. At this time, other valves are closed, and the power pump 1 is turned on first, then Open the F4 valve. After opening the F4 valve, the liquid can be directly extracted. The pure water pipe of the F4 valve is inserted into the pure water container; the pure water is pumped into the high level sensor 3 of the sampling tank 2, and the high level sensor 3 detects After the liquid is released, a signal is sent to the control system, the control system controls the power pump 1 to stop pumping liquid, then the control system controls the F4 valve...

Embodiment 3

[0067] The present embodiment provides a method for detecting calcium hardness, including the detection of the second concentration solution concentration, the second concentration is greater than the first concentration, the method is as follows:

[0068] The difference between this embodiment and the second embodiment lies in the first step: the second step in the instrument calibration process: taking a sample with a known concentration.

[0069]In this embodiment, the process of taking a sample with a known concentration is: the system executes "1. Take pure water to the titration tank 7" in the first step of the instrument calibration process in the second embodiment; the control system first controls the power pump 1 Start the pumping work, and then the control system controls the F5 valve of the multi-position valve 5 to open. At this time, the F5 valve is not opened, and the power pump 1 is opened first, and then the F5 valve is opened. After the F5 valve is opened, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com