A compact high-sensitivity MEMS micro-capacitive sensor

A micro-capacitive, sensor technology, applied in electrostatic sensors, sensors, sensor types, etc., can solve the problems of small effective area, low mass range, small size of MEMS sensor, etc., achieve significant impedance transformation, and improve the effect of detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

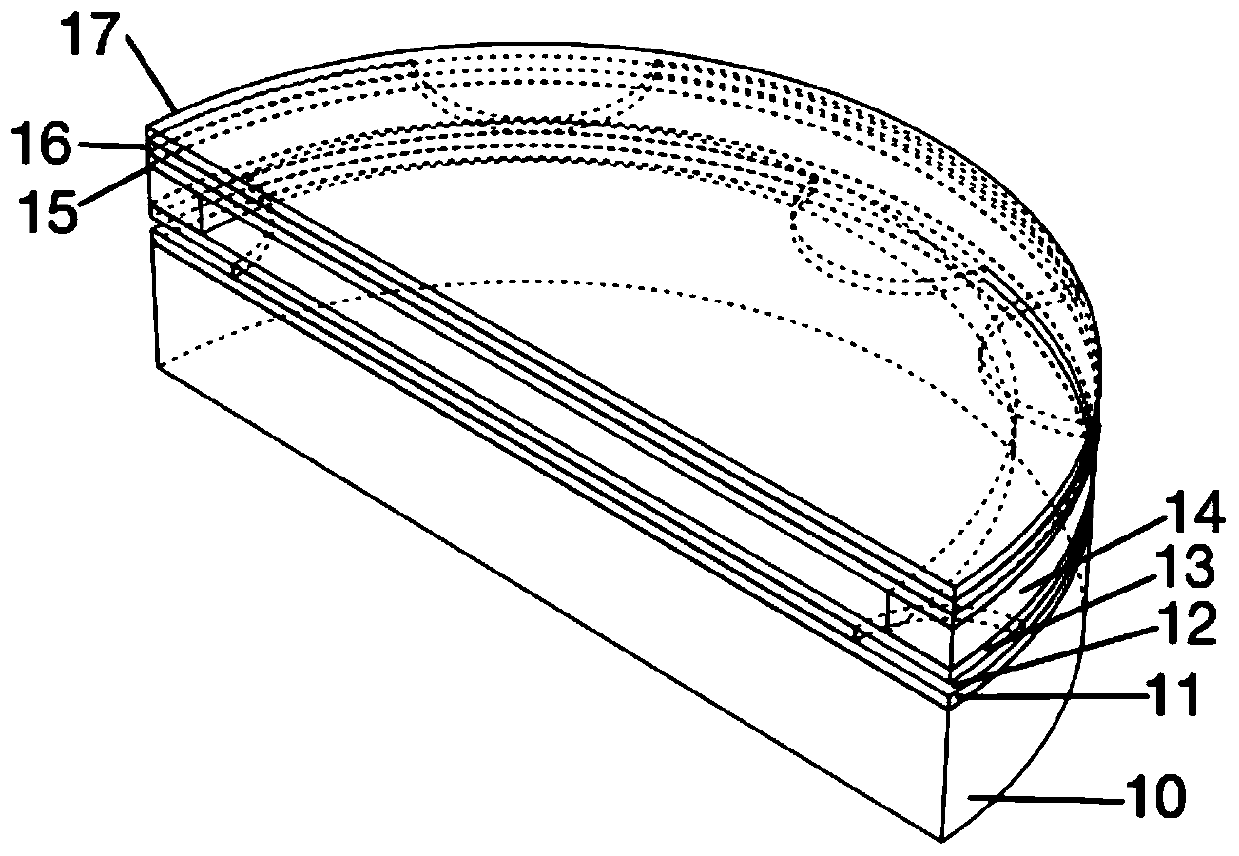

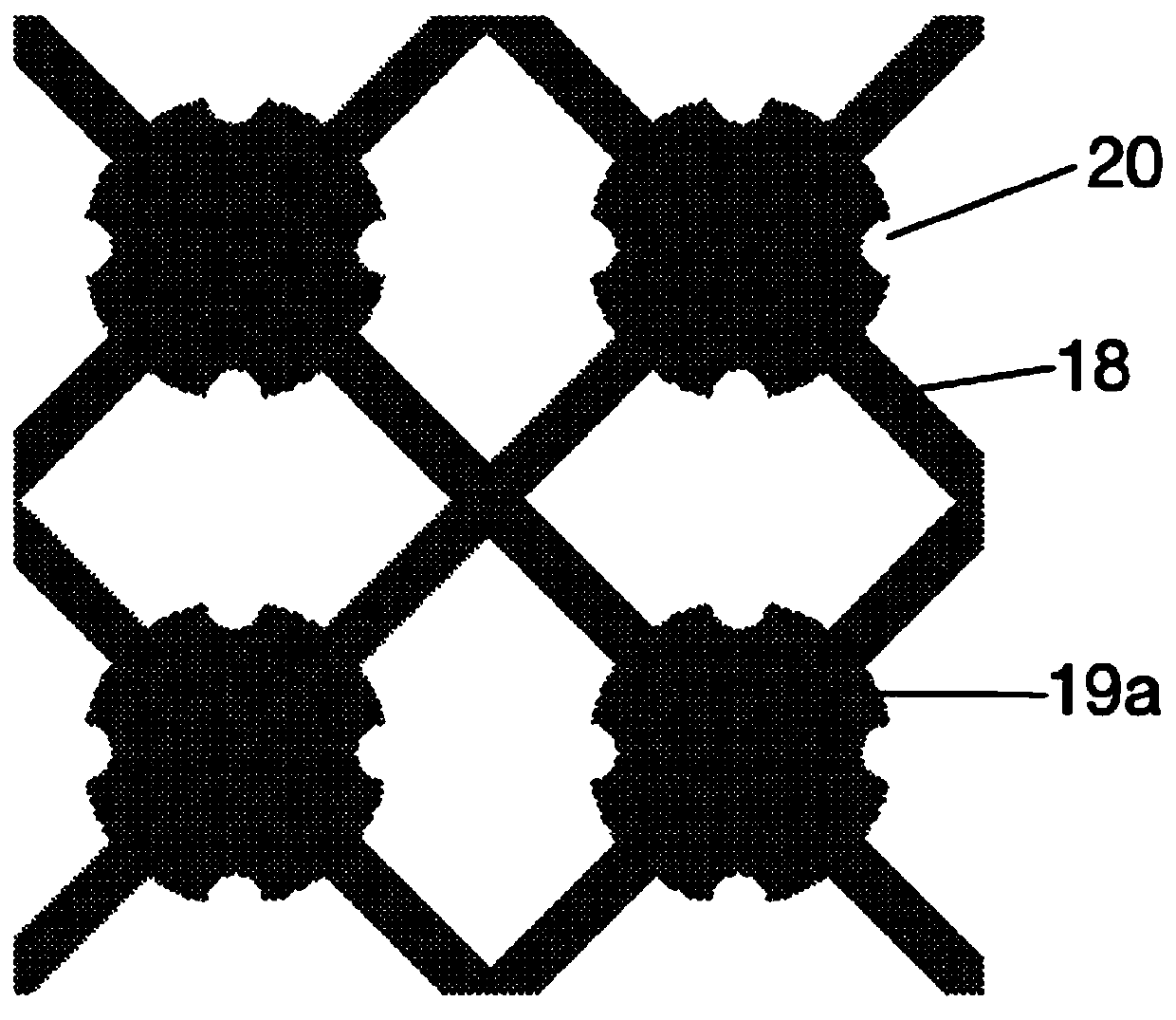

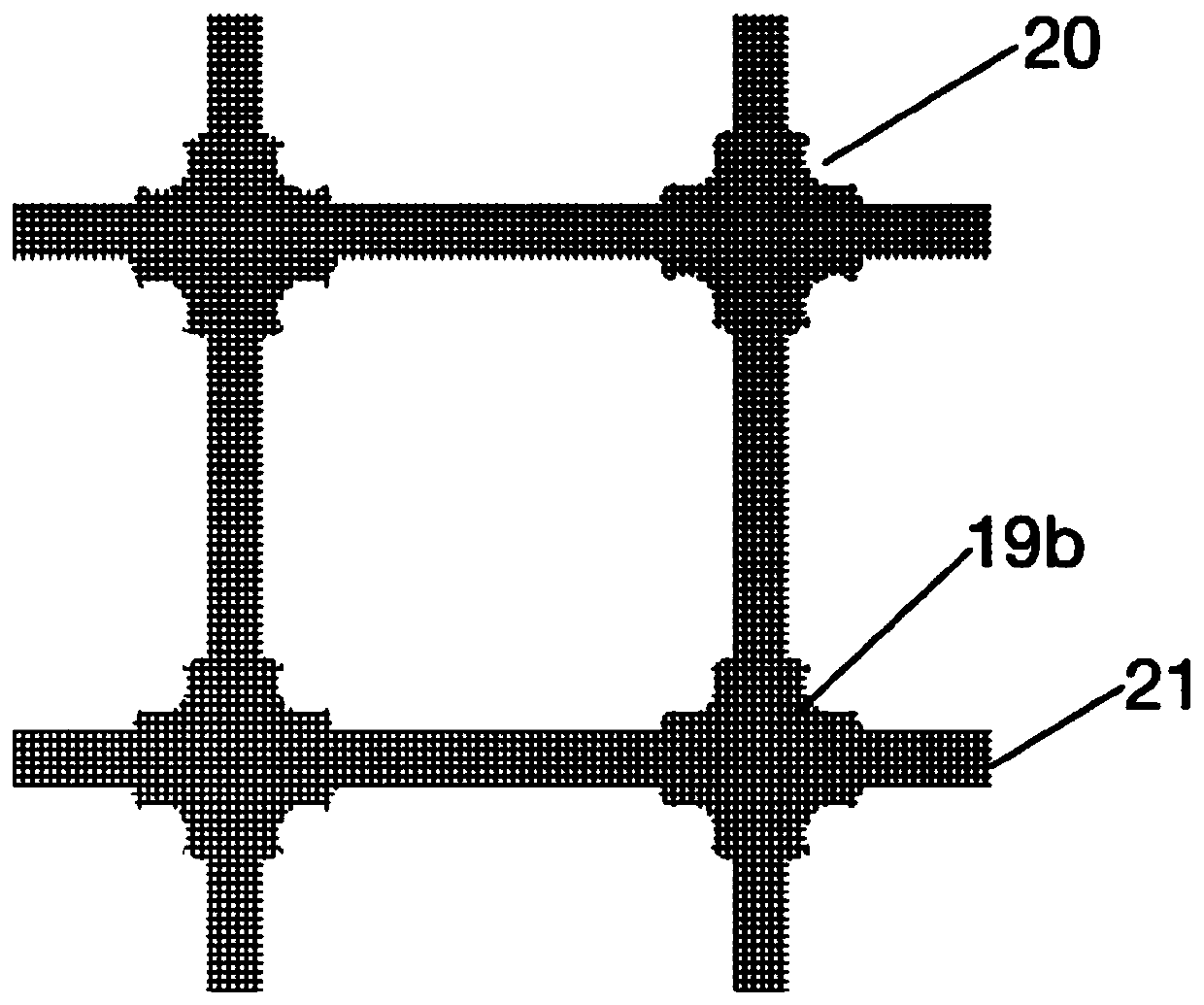

[0023] The MEMS capacitive sensor includes a base 10 , a lower isolation layer 11 , a lower electrode layer 12 , an upper isolation layer 13 , a sacrificial layer 14 , a diaphragm layer 15 , an upper electrode layer 16 , and an insulating layer 17 arranged sequentially from bottom to top. Both the lower electrode layer 12 and the upper electrode layer 16 include at least one electrode array unit 22 , and the electrode array unit 22 includes a plurality of electrode units 19 .

[0024] The base 10 acts as a support and fixation, and can be used as a silicon wafer. The lower isolation layer 11 supports the lower electrode layer 12 and plays an insulating and protective role, which can be SiO 2 、SiN x and other insulating materials. Both the lower electrode layer 12 and the upper electrode layer 16 include an electrode array unit 22 formed by a plurality of electrode units 19 . The upper electrode layer 16 is located above the lower electrode layer 12, and an electrode unit 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com