Formula car carbon fiber half shaft bearing large torque and preparation method thereof

A formula racing car, carbon fiber technology, applied in shafts, couplings, shafts and bearings, etc., can solve the problems of light weight, insufficient resonance, large moment of inertia, and influence on transmission smoothness, so as to improve the car's speed-up performance and small rotation The effect of improving inertia and smoothness of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

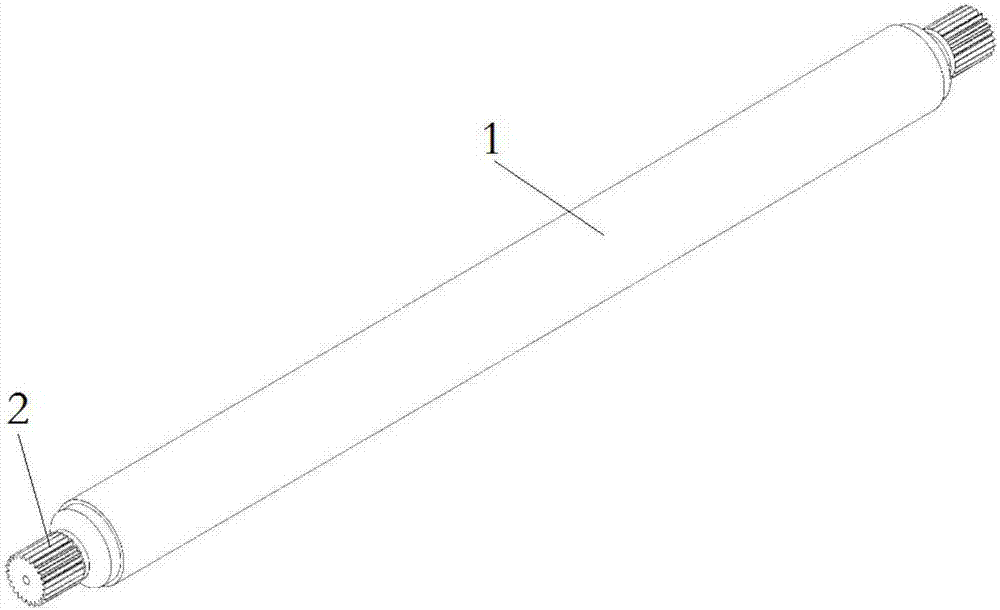

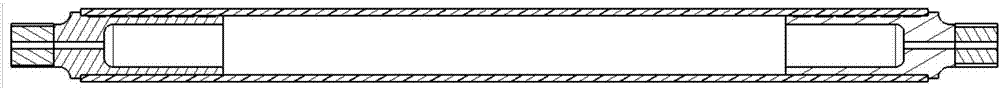

[0025] As shown in the figure, a carbon fiber half shaft for a formula racing car with high torque capacity includes a carbon fiber half shaft main body 1 and a half shaft joint 2. The carbon fiber half shaft main body 1 is in the shape of a hollow sleeve, and the half shaft joint 2 is made of metal. The two ends of the carbon fiber half-axis main body 1 are bonded and fixed with oxygen resin structural glue.

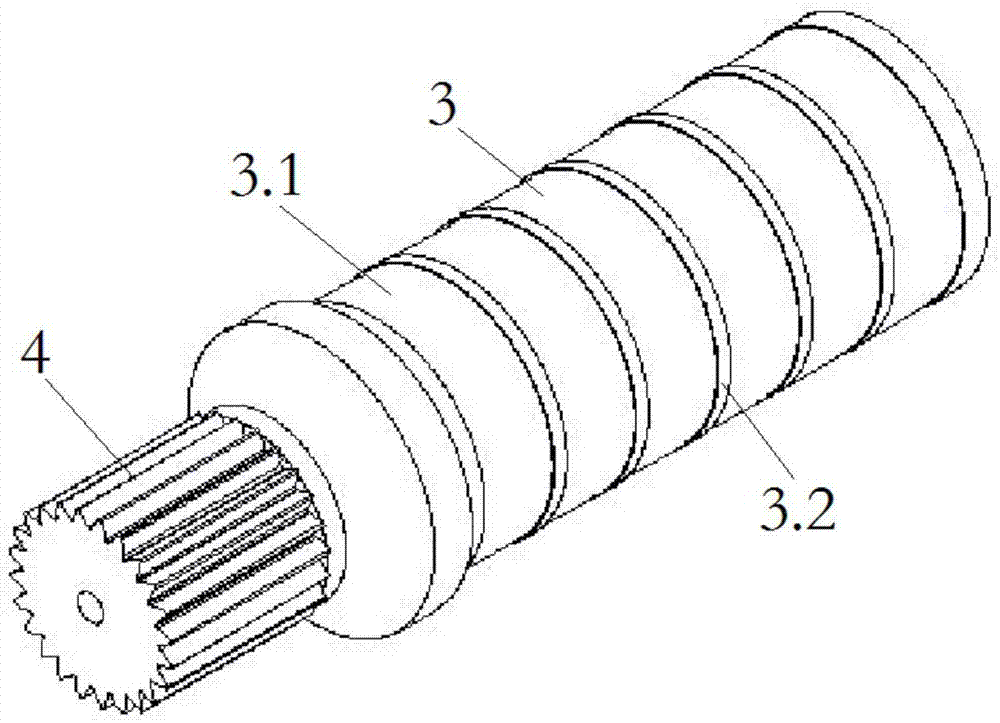

[0026] Wherein, the half-shaft joint 2 can be divided into a glue joint section 3 and a spline section 4 of a three-ball joint. The bonding section 3 includes a bonding area 3.1 and several centering bosses 3.2 with the same radius as the inner diameter of the carbon fiber half shaft main body 1. Axiality, the bonding area 3.1 and the centering boss 3.2 are alternately arranged, and the bonding area 3.1 needs to be roughened before ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com