Storage device for grounding wire winding frames for power plant

A technology for storing devices and grounding wires, which is applied in storage devices, transportation, and packaging, and can solve unfavorable access to high-voltage short-circuit grounding wires and winding racks, increase the space occupied by grounding wire winding racks, and prevent high-voltage short-circuiting grounding wires. Damage and other problems, to facilitate recording and management, reduce collision deformation, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The specific embodiments described here are only used to explain the present invention, and are not intended to limit the content of the invention.

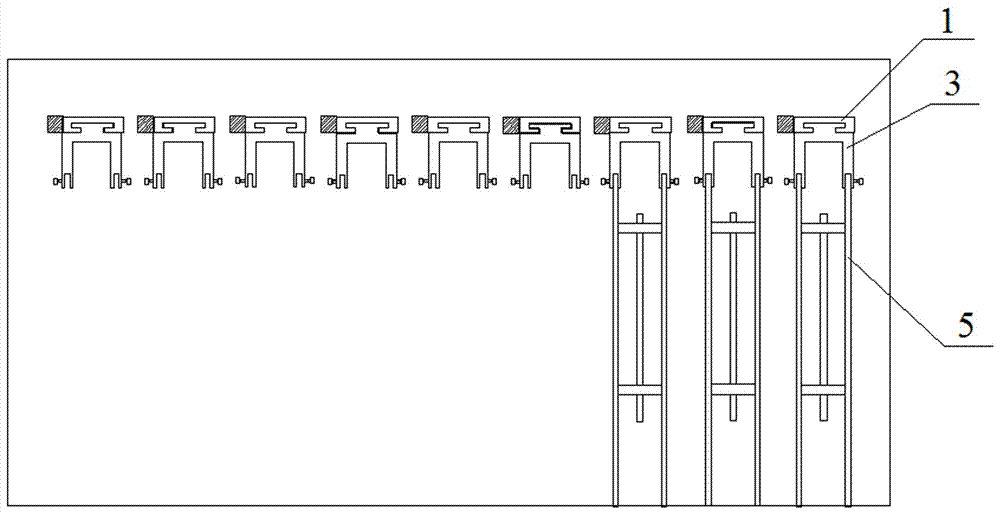

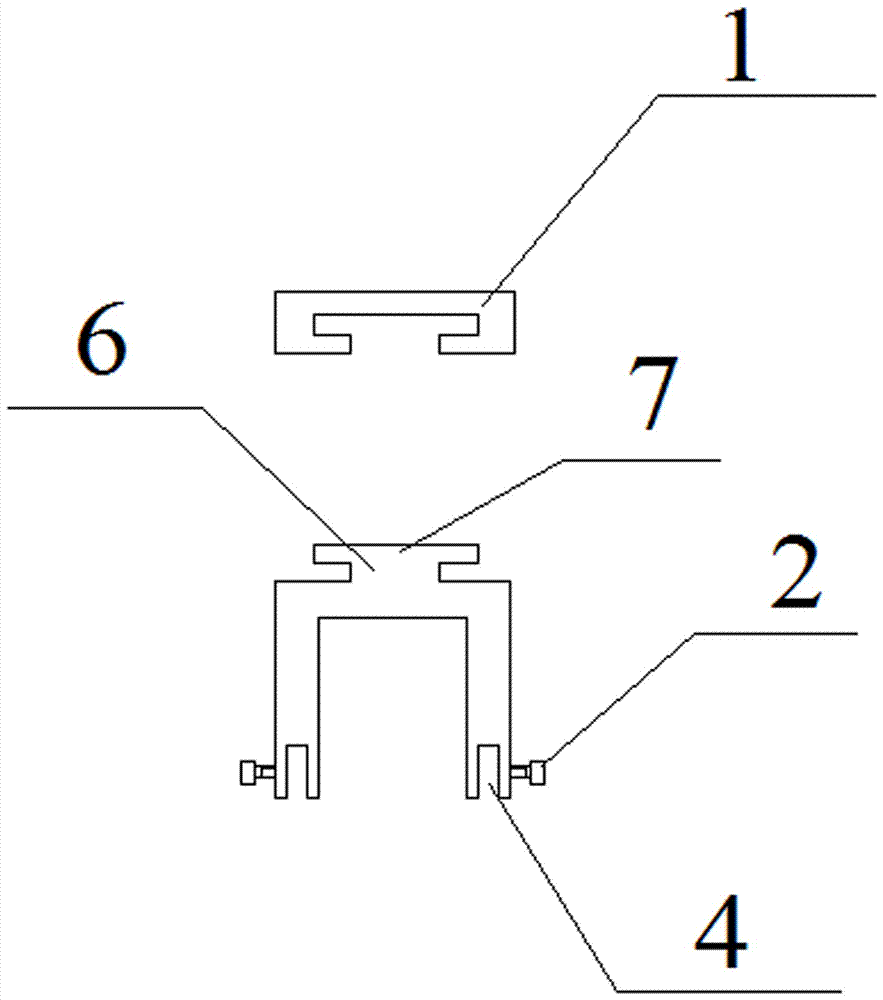

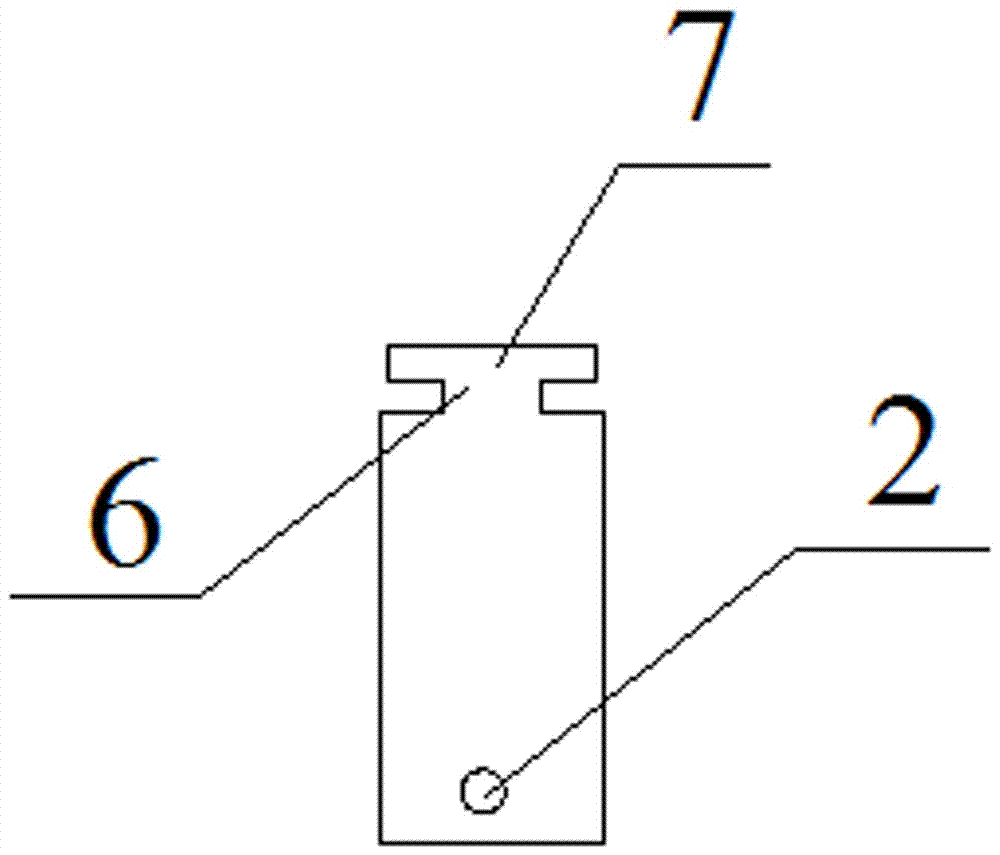

[0023] Such as figure 1 , 2 . 3 shows a storage device for a grounding wire winding frame for a power plant. The storage device includes a storage track 1 and a storage fixture 3. It is characterized in that: the storage track 1 is a plurality of side-by-side and downward openings. Concave guide rails, a plurality of concave guide rails are arranged at the same height and perpendicular to the wall, and the horizontal intervals between adjacent concave guide rails are the same; each concave guide rail is connected with a storage fixture 3, and the storage fixture 3 includes sliding mechanism and the clamping mechanism for clamping the grounding wire winding frame 5, the sliding mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com