Safety lock used for aloft work device and using method of safety lock

A technology for working at heights and safety locks, which is applied to lifting devices, safety devices of lifting equipment, etc., can solve the problems of complex safety lock structure, complex internal structure, low reliability, etc., so as to ensure the safety of working at heights and personnel, avoid Potential safety hazards, ease of installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, but the present invention is not limited to this embodiment:

[0034] A safety lock for an aerial work device, comprising:

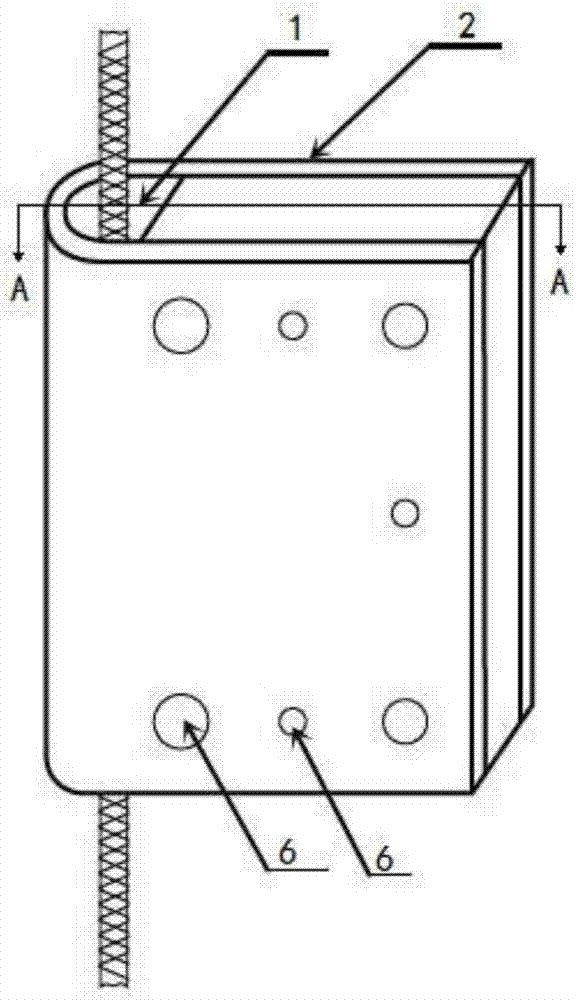

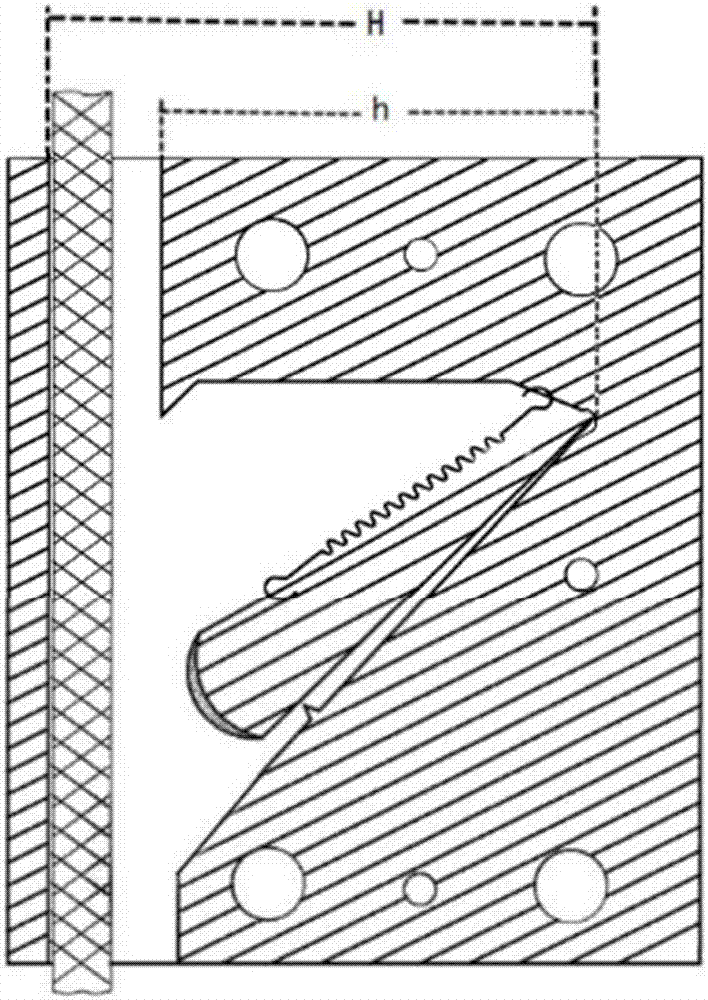

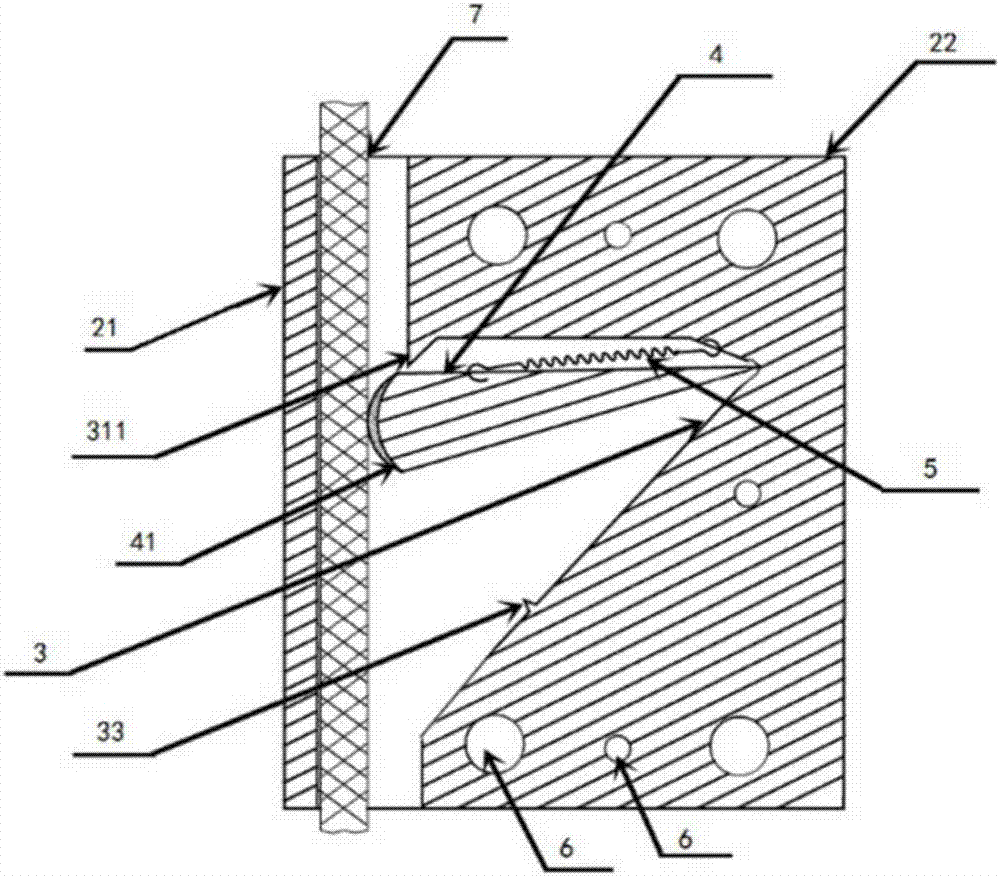

[0035] A lock body 2 with a vertical through hole 1 and a groove 3, the outer side of the vertical through hole 1 is the lock shell 21 and the inner side is the lock core 22, the groove 3 is located on the side of the lock core 22, the groove 3 The inner cavity is provided with a pendulum 4 and an elastic element 5; the groove 3 includes a waterproof chamfer 311, a groove upper plane 312, a spring fixing surface 313, and a groove slope 314 to form a V-shaped groove 3 cavity, so The intersection of the spring fixing surface 313 and the groove slope 314 is a rounded corner, the swing fulcrum of the pendulum 4 is located in the rounded corner, one end of the elastic element 5 is fixed on the spring fixing surface 313 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plane angle | aaaaa | aaaaa |

| Plane angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com