Fiber composite phase change energy storage material, pipe made from the material and manufacturing method thereof

A technology of phase-change energy storage materials and fiber composites, applied in heat exchange materials, chemical instruments and methods, pipes, etc., can solve the problems of poor energy storage effect and high cost, achieve small thermal conductivity, reduce production costs, and ensure The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] (1) Prepare cement paste.

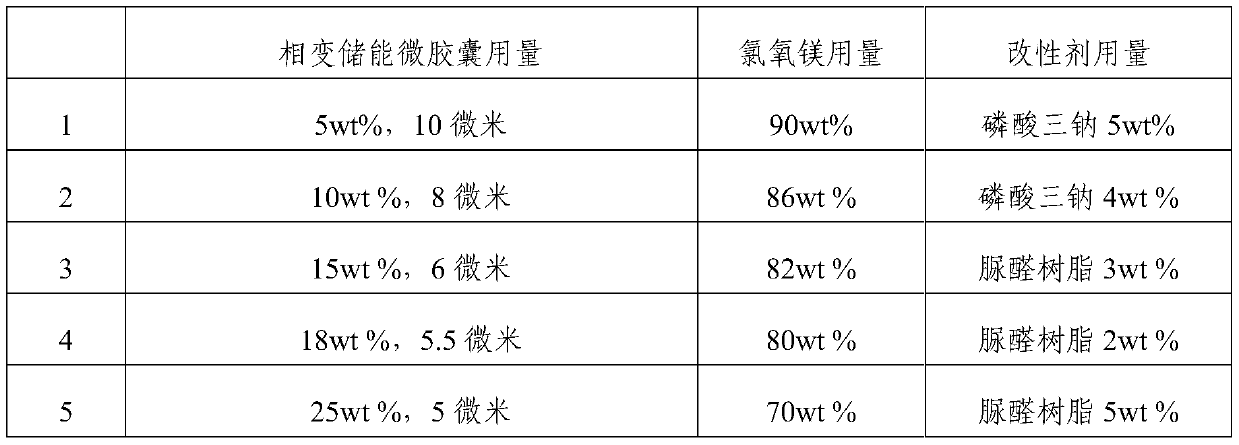

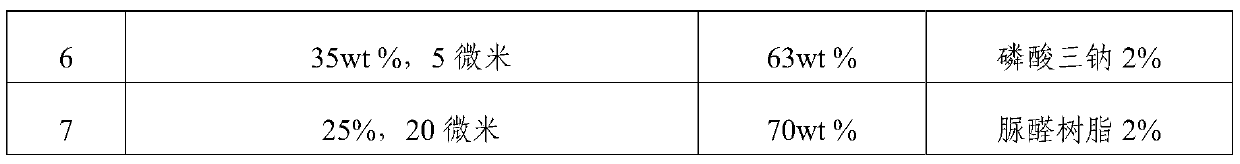

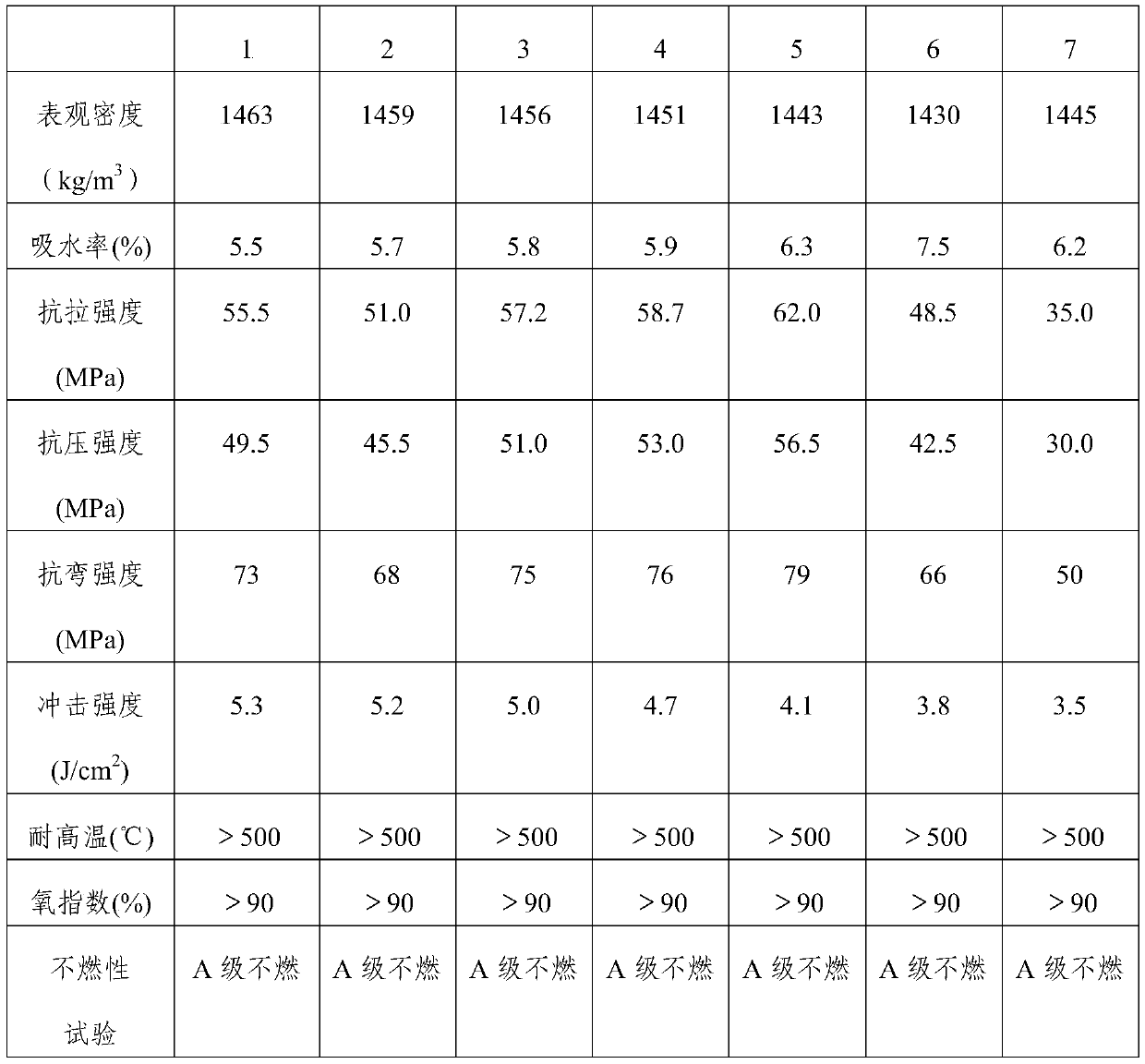

[0076] Prepare raw materials according to Table 1, then add phase change energy storage microcapsules, magnesium oxychloride and modifier into water and stir evenly to prepare cemented slurry.

[0077] The cement slurry must be stirred evenly so that the phase change energy storage microcapsules and magnesium oxychloride are fully mixed to avoid mixing raw materials. Moreover, the cemented slurry must be used while mixing, and the slurry with slurry must not be used.

[0078] (2) Coating molding.

[0079] Molds can be made in advance using materials such as wood, planks, plywood, and fiberboard. The mold used in the present invention is made of fiberboard, and the following examples will not be described again. But one thing needs to be explained, although the embodiments of the present invention all take fiberboard as an example, it does not mean that all the molds used in the present invention are made of fiberboard.

[0080] Choose a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com