MnIn2S4/TiO2 nanotube bundle composite photo-anode material and preparation method and application thereof

An anode material, mnin2s4 technology, applied in the direction of nanotechnology, nanotechnology, metal material coating technology, etc., can solve the problems that Q235CS has no electronic energy storage effect, the photocurrent density is not very high, and the hydrothermal reaction time is long. Improved photocurrent response results, high preparation steps and technical feasibility, and reduced distance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

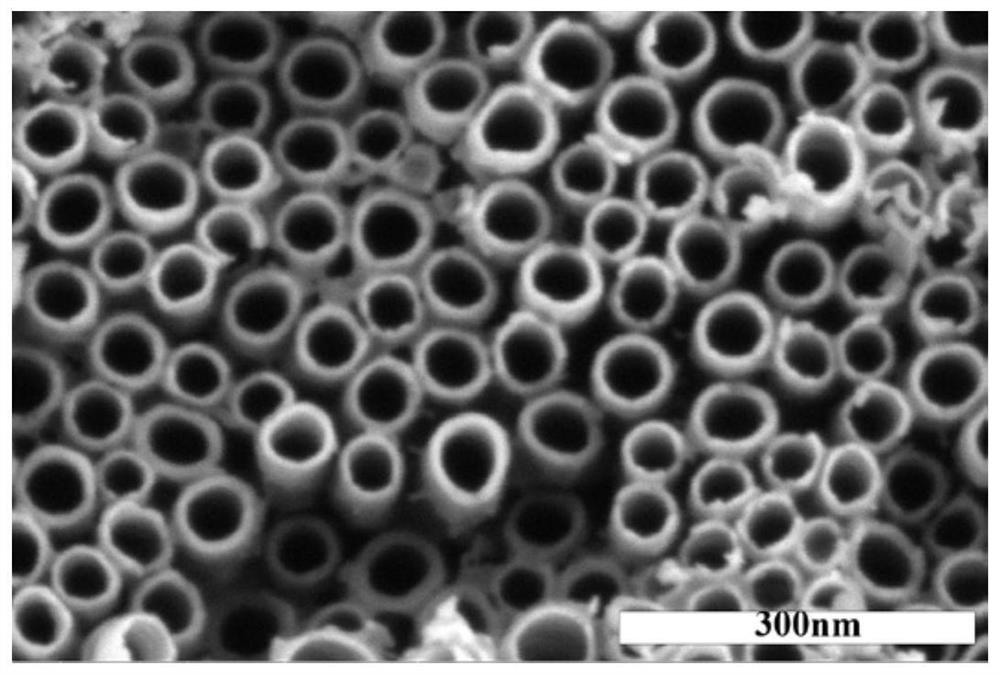

[0036] TiO 2 Preparation of nanotube bundles:

[0037] ① Pretreatment of titanium substrate: before chemical polishing of the surface of titanium substrate, the pretreatment operation of tablet pressing on the operating table of the tablet press, absolute ethanol and distilled water were ultrasonically cleaned for 30 minutes, and the titanium foil (10mm×30mm×0.1 mm) smooth and clean surface. The titanium substrate was then placed in a solution of 0.9 g NH 4 F, 5mL H 2 O, 12mL HNO 3 and 12mL H 2 o 2 React in the chemical polishing solution configured for about 30s. Take them out one by one, rinse them with absolute ethanol and pure water alternately, and store them in absolute ethanol solution for later use.

[0038] ②TiO2 2 Preparation of nanotube bundle thin film: the traditional two-electrode system is composed of the taken out titanium sheet as the working electrode and the platinum sheet as the counter electrode in 80ml ethylene glycol, 0.44g NH 4 F and 8ml H 2 I...

Embodiment 2

[0049] TiO 2 Preparation of nanotube bundles:

[0050] ① Pretreatment of titanium substrate: before chemical polishing of the surface of titanium substrate, the pretreatment operation of tablet pressing on the operating table of the tablet press, absolute ethanol and distilled water were ultrasonically cleaned for 30 minutes, and the titanium foil (10mm×30mm×0.1 mm) smooth and clean surface. The titanium substrate was then placed in a solution of 0.9 g NH 4 F, 5mL H 2 O, 12mL HNO 3 and 12mL H2 o 2 React in the chemical polishing solution configured for about 30s. Take them out one by one, rinse them with absolute ethanol and pure water alternately, and store them in absolute ethanol solution for later use.

[0051] ②TiO2 2 Preparation of nanotube bundle thin film: the traditional two-electrode system is composed of the taken out titanium sheet as the working electrode and the platinum sheet as the counter electrode in 80ml ethylene glycol, 0.44g NH 4 F and 8ml H 2 In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Photocurrent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com