Prestressed anchorage device with replaceable anchorage and construction method of installation and cable replacement thereof

An anchoring device and construction method technology, applied in bridge reinforcement, erection/assembly of bridges, construction, etc., can solve problems such as inability to change directions, inapplicability, etc., and achieve the effects of convenient cable replacement, cost saving, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

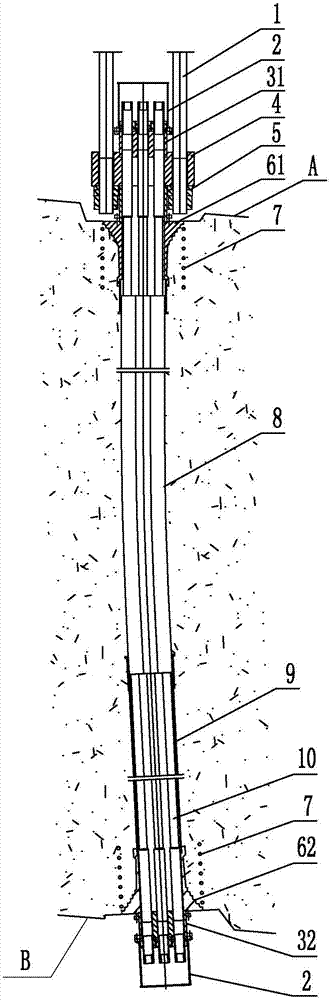

[0050] A replaceable anchor prestressed anchoring device:

[0051] like figure 1 As shown, the replaceable anchorage prestressed anchoring device includes a prestressed concrete anchoring part and a main cable strand connecting part for connecting with the main cable strand. The main cable strand connecting part includes a pull rod 1, a protective Cover 2, front support plate 31, rear support plate 32, connector 4 and nut assembly 5; the prestressed concrete anchoring part includes a pre-embedded assembly embedded in the concrete, anchor strands, and the pre-embedded assembly includes The upper anchor backing plate 61, the lower anchor backing plate 62, the spiral reinforcement 7 and the pre-embedded pipe, the anchor strands are finished cables 10 that have been processed in the factory, and there is no anti-corrosion material in the pre-embedded pipe of the pre-embedded components;

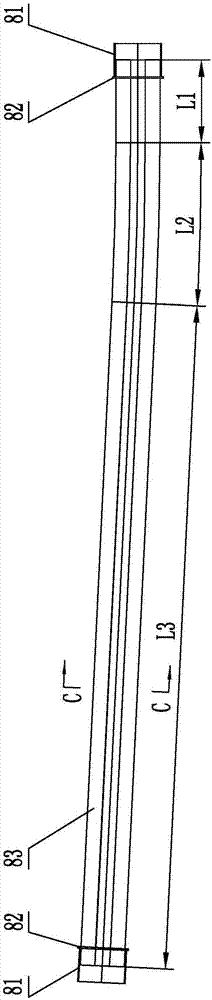

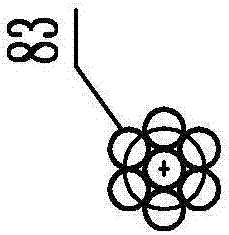

[0052] like Figure 2-1~Figure 2-1 As shown, the pre-embedded pipe includes a sub-wire dive...

Embodiment 2

[0056] A method of installation and construction of a replaceable anchorage prestressed anchorage device:

[0057] It is an installation and construction method of a replaceable anchorage prestressed anchoring device described in Embodiment 1 of the present invention, including the following steps:

[0058] Step 1: Embedded parts installation: pre-embed the lower anchor plate 62, spiral reinforcement 7, straight embedded pipe 9, split-wire steering embedded pipe 8, and upper anchor plate 61 on site, pour concrete in layers and then cure until design strength;

[0059] Step 2: Connector installation: install and fix the connector 4 on the end face of the upper anchor plate 61 with bolts at the upper end;

[0060] Step 3: Anchor Strand Installation:

[0061] Step 3-1: Finished cable installation: Put the finished cable 10 that has been prepared in the factory through the front support plate 31, the connector 4, the upper anchor plate 61, and the split wire steering embedded pi...

Embodiment 3

[0068] A method for changing cables of a replaceable anchorage prestressed anchorage device, which is a method for changing cables of the replaceable anchorage prestressed anchorage device described in Embodiment 1 of the present invention, comprising the following steps:

[0069] Step 1: Remove the protective cover: remove the upper and lower protective cover 2;

[0070] Step 2: unloading of the old finished cables: use devices such as jacks, braces, and tension rods at the lower end to tension and loosen any one of the finished cables 10;

[0071] Step 3: Remove the old finished cable: connect the old cable with an index cable on the rear anchor surface / front anchor surface, pull out an unloaded old finished cable 10 from the tunnel on the front anchor surface / rear anchor surface, and remove it;

[0072] Step 4: installation of the new finished cable: connect the new cable with a traction cable on the front anchor surface / rear anchor surface, and pull in a new finished cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com