Engine brake oil way control device and usage method thereof

A technology for engine braking and control devices, which is applied in the direction of engine control, engine components, machines/engines, etc., can solve the problems of high manufacturing accuracy, poor braking effect, and high production cost, and achieve high manufacturing accuracy requirements, less error, and The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

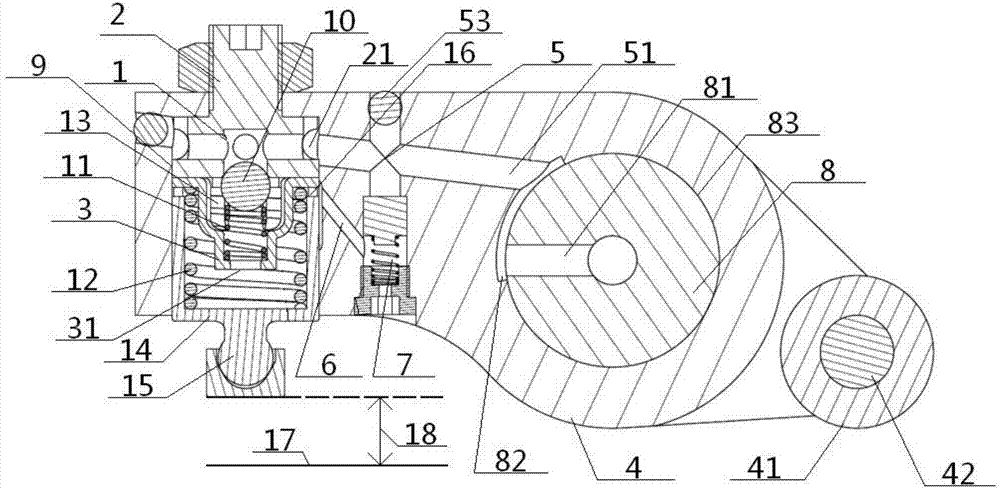

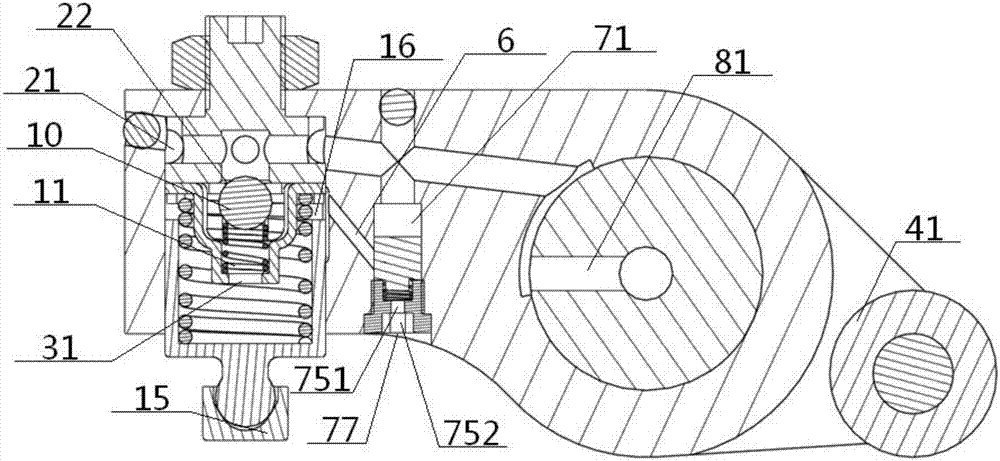

[0059] see Figure 1 to Figure 9, an engine brake oil circuit control device, including a rocker arm 4 and a brake actuator 1 set on it, a rocker arm shaft 8 and a rocker arm roller 41, and the rocker arm shaft 8 passes through the brake oil circuit 5 It communicates with the brake actuator 1, and the side of the brake actuator 1 communicates with the oil discharge passage 6. The interior of the brake actuator 1 is provided with a brake piston 14 that moves up and down along its axial direction, and the bottom of the brake piston 14 It is connected with the elephant foot 15 directly below it, and a valve gap 18 is formed between the bottom of the ball socket 152 in the elephant foot 15 and the valve yoke 17 directly below it;

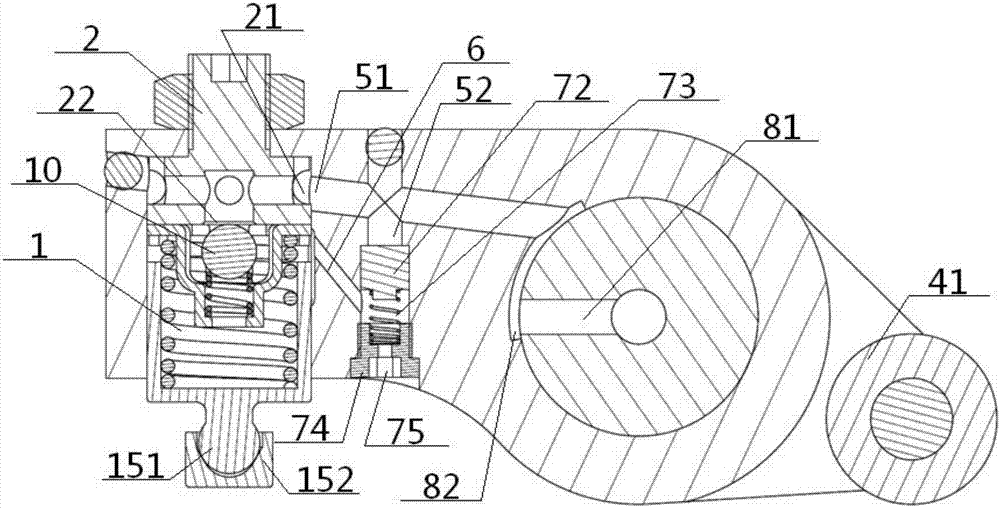

[0060] The engine brake oil circuit control device also includes a control valve 7 arranged inside the rocker arm 4. The control valve 7 includes a control chamber 71 and a control piston 72, a control spring 73, and a control chamber arranged in sequen...

Embodiment 2

[0064] Basic content is the same as embodiment 1, the difference is:

[0065] The method of use also includes an operating process under braking conditions. The operating process under braking conditions includes the following steps in sequence: under braking conditions, the pressure of the oil entering the brake oil circuit 5 through the rocker shaft 8 is greater than that of the control spring 73 spring force, the engine oil entering the longitudinal oil passage 52 continuously compresses the control spring 73 until the descending control piston 72 blocks the oil discharge passage 6 so that the oil in the oil discharge passage 6 no longer enters the control chamber 71. At this time, the inclined The machine oil flowing into the brake oil chamber 13 from the oil passage 51 no longer flows out through the unloading oil passage 6, and the brake oil chamber 13 forms a closed chamber. When the machine oil continues to enter, the ball socket 152 in the elephant foot 15 is driven by...

Embodiment 3

[0067] Basic content is the same as embodiment 2, the difference is:

[0068] The brake actuator 1 includes a brake chamber 9, an adjusting bolt 2, a ball valve 10, a ball valve spring 11, a ball valve spring seat 3, a brake spring 12, a brake oil chamber 13, a brake piston 14 and an elephant foot 15. The bottom end of the adjustment bolt 2 is located inside the brake chamber 9, and the top end of the adjustment bolt 2 passes through the brake chamber 9 and the rocker arm 4 in sequence and is fixedly connected with the outer wall of the rocker arm 4 (preferably, the top end of the adjustment bolt 2 is adjusted by adjusting The nut 23 is fixedly connected with the outer wall of the rocker arm 4), the side and the bottom surface of the bottom of the adjustment bolt 2 are provided with corresponding side oil holes 21 and bottom surface oil holes 22 respectively, and the high port of the oblique oil passage 51 passes through the side oil holes 21 It communicates with the oil hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com