Clutch with gear rack and planetary mechanism

A technology of planetary mechanism and rack and pinion, which is applied in the field of clutches, can solve the problems of thermal fracture, large energy consumption, uneven pressing force, etc., and achieve the effects of improving fuel economy, improving reliability, and not being prone to fatigue fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The purpose of the present invention will be further described in detail through specific examples below, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

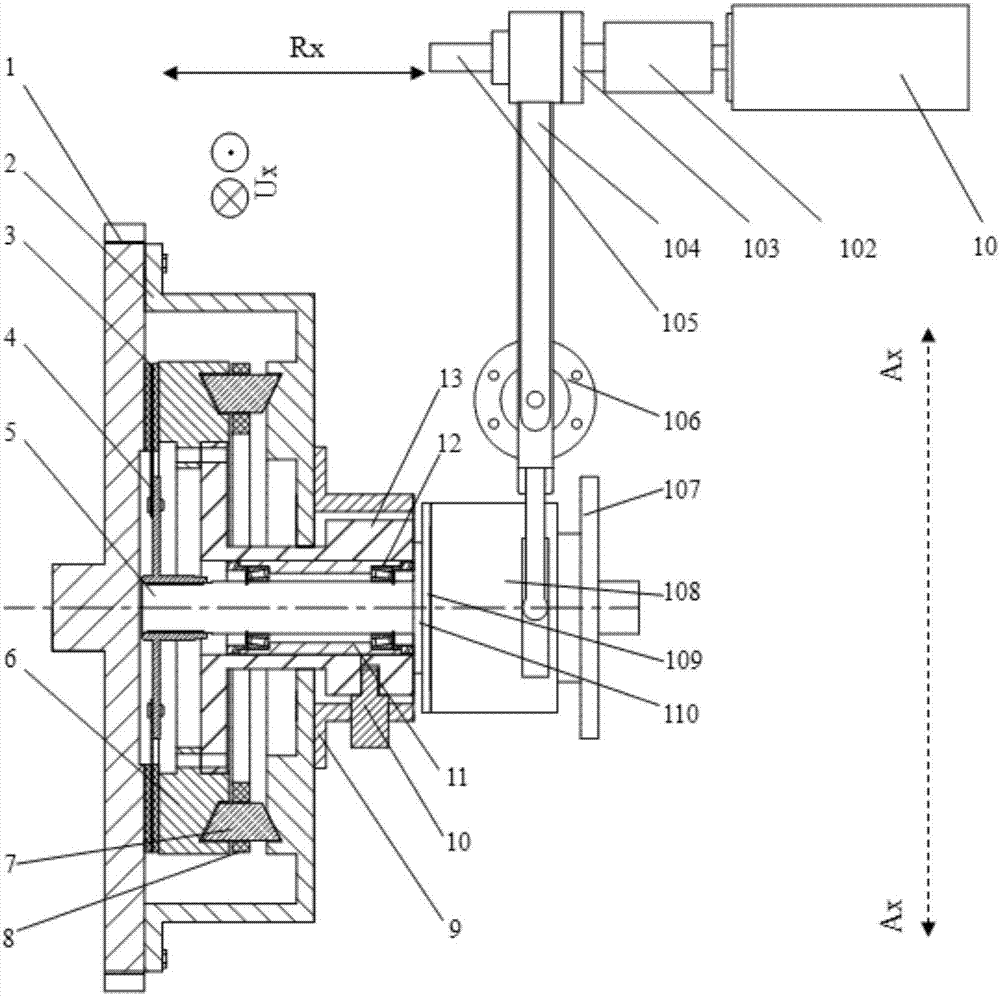

[0034] figure 1 The general assembly diagram of the structure of the invention is shown. Wherein, the clutch cover assembly mechanism is a sectional view, the radial direction is Ax, the axial direction is Rx, and the circumferential rotation direction is Ux.

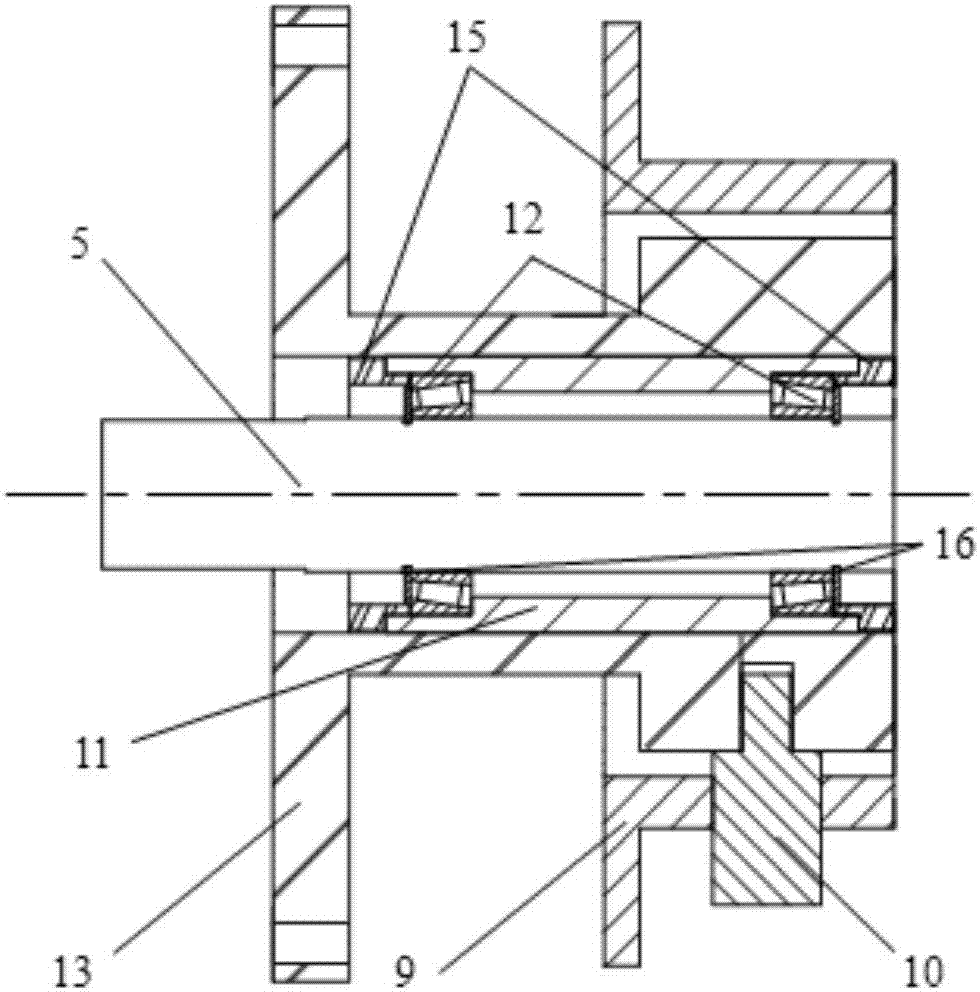

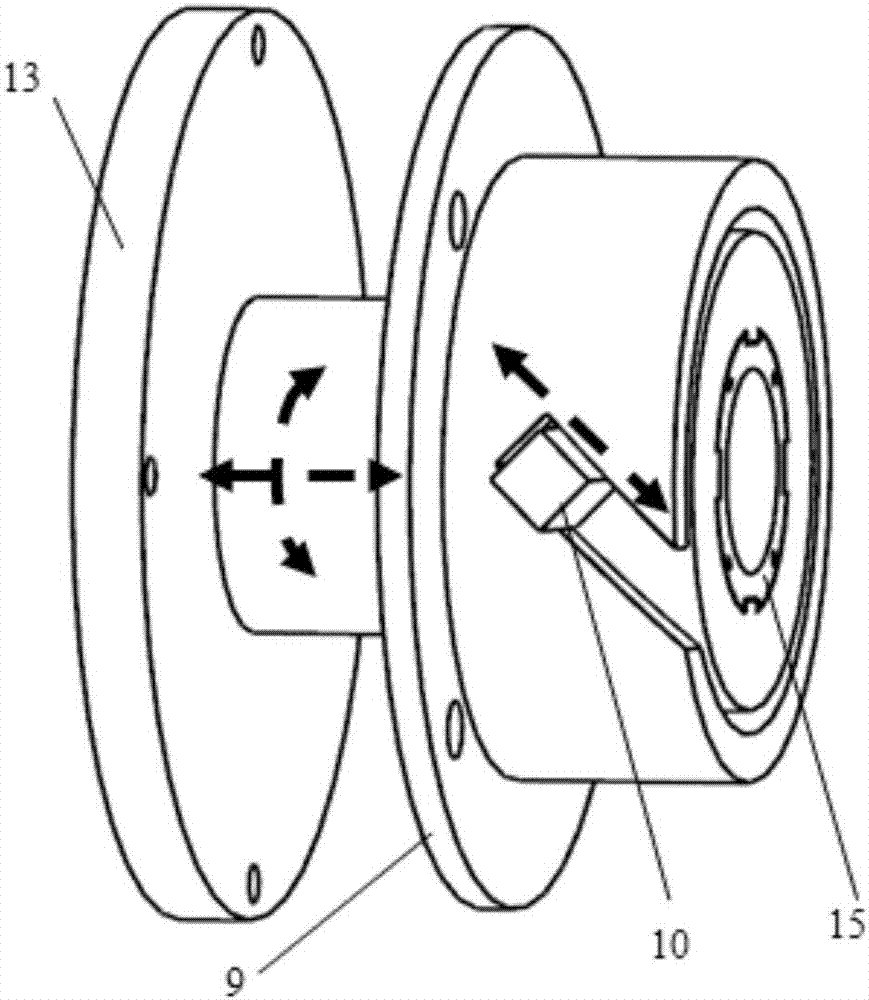

[0035]A clutch with a rack and pinion and a planetary mechanism, including a clutch cover assembly mechanism and a clutch engagement-separation control mechanism, the clutch cover assembly mechanism includes a fixedly connected flywheel 1 and a clutch cover 2, which are arranged on the The transmission input shaft 5 in the clutch cover 2, the driven plate 4 and the pressure plate 6 are sequentially arranged on the transmission input shaft 5 along the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com