Sheet and ladder type air distribution device for circulating fluidized bed boiler

A circulating fluidized bed and air distribution device technology, applied in the field of waste incinerators, can solve the problems of aggravated flow field disorder, impact wear, difficult discharge, etc., to achieve improved fluidization uniformity, strong directional blowing ability, and improved impact wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

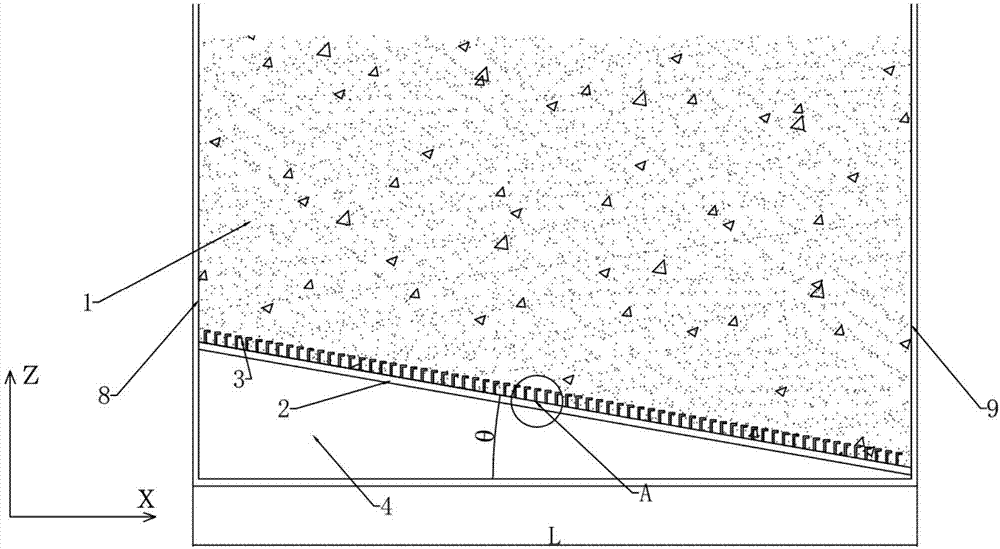

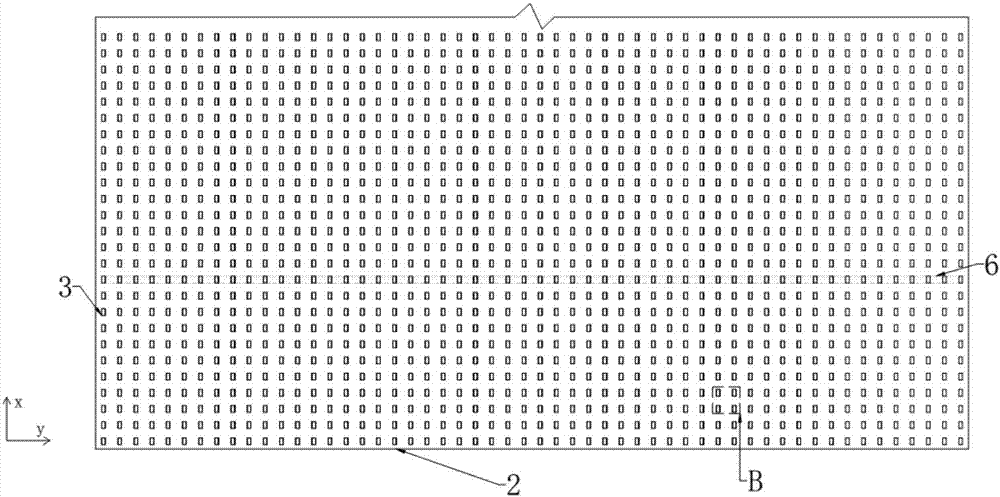

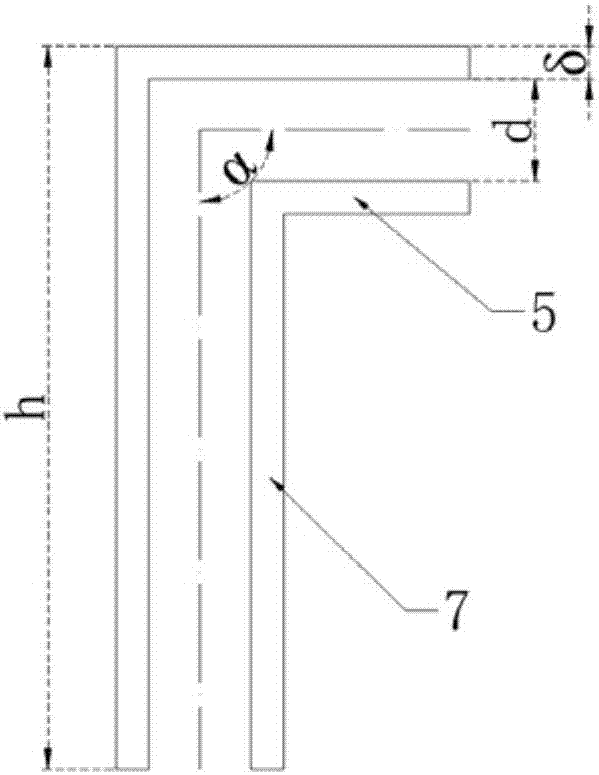

[0021] The principle, specific structure and implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] figure 1 It is a structural schematic diagram of a sheet-shaped stepped air distribution device for a circulating fluidized bed boiler of the present invention, figure 2 It is a top view of the inclined air distribution plate with "Γ"-shaped directional air caps, which shows that the "Γ"-shaped directional air caps 3 are stepped in the height direction and sheet-shaped in the horizontal direction. The air distribution device includes an air chamber 4, an inclined air distribution plate 2 and a "Γ"-shaped directional air cap 3 arranged on the inclined air distribution plate 2, and the "Γ"-shaped directional air cap main air duct 7 is installed vertically on the On the inclined air distribution board 2; the same row of "Γ"-shaped directional air caps 3 are on a straight line, showing a sheet structure, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com