Heat-recovery air-cooling heat pump drying system applicable to large temperature difference

An air-cooled heat pump and drying system technology, applied in heat recovery system, heat pump, drying and other directions, can solve the problems of unavailability of moisture exhaust waste heat, single drying method, serious environmental pollution, etc., and achieves ingenious design optimization of the unit, The effect of broadening the application field and improving the dehumidification energy consumption ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

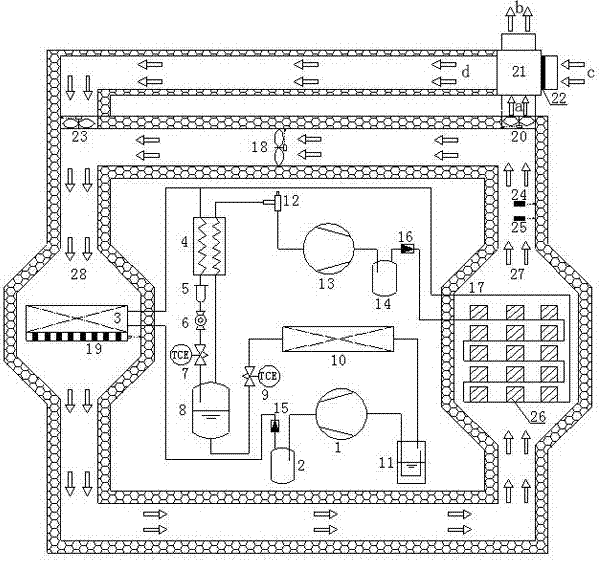

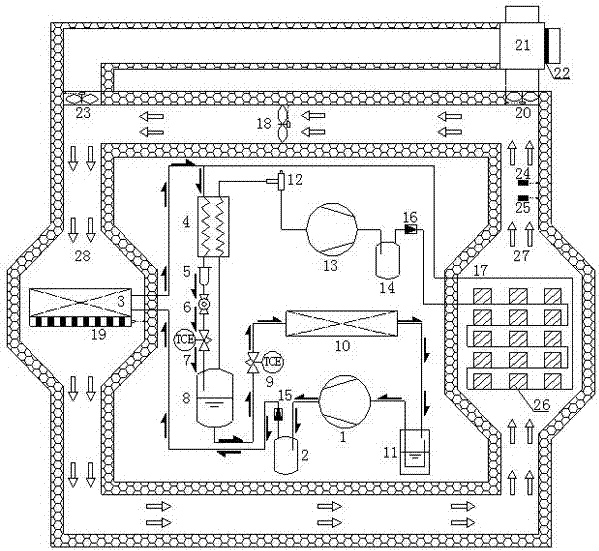

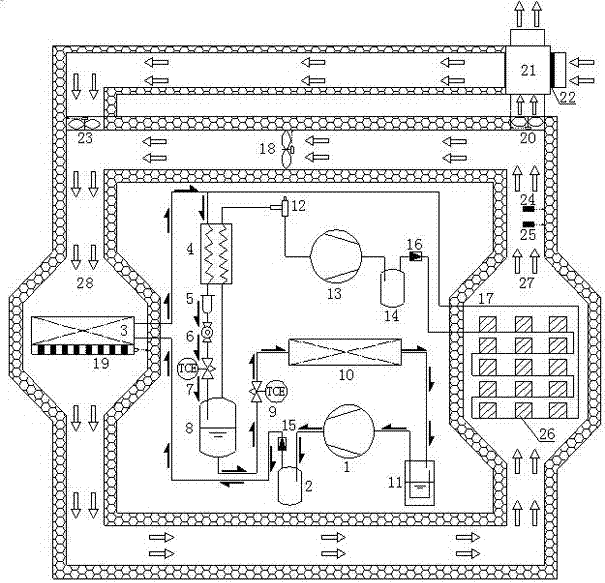

[0027] Such as figure 1 As shown, the present invention includes a three-pressure air-cooled heat pump subsystem and a drying medium circulation subsystem. The three-pressure air-cooled heat pump subsystem includes a main road compressor 1, a main road oil separator 2, and a main road condenser 3 , recooler 4, medium-pressure gas-liquid separator 8, evaporator 10, low-pressure gas-liquid separator 11, auxiliary circuit compressor 13, auxiliary circuit oil separator 14 and auxiliary circuit condenser 17, the discharge of the main circuit compressor 1 The gas port is connected with the inlet of the main road condenser 3 through the main road oil separator 2; the outlet of the main road condenser 3 is connected with the main road inlet of the recooler 4 and the outlet of the auxiliary road condenser 17 respectively; The outlet of the main path of the subcooler 4 is connected to the inlet of the medium-pressure gas-liquid separator 8; the two outlets of the medium-pressure gas-liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com