Engine dynamic valve gap signal detecting device and engine dynamic valve gap signal detecting method

A valve clearance and signal detection technology, applied in the direction of mechanical clearance measurement, etc., can solve the problem that the feeler gauge cannot test the valve clearance, etc., and achieve the effect of light weight, high measurement accuracy and strong portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

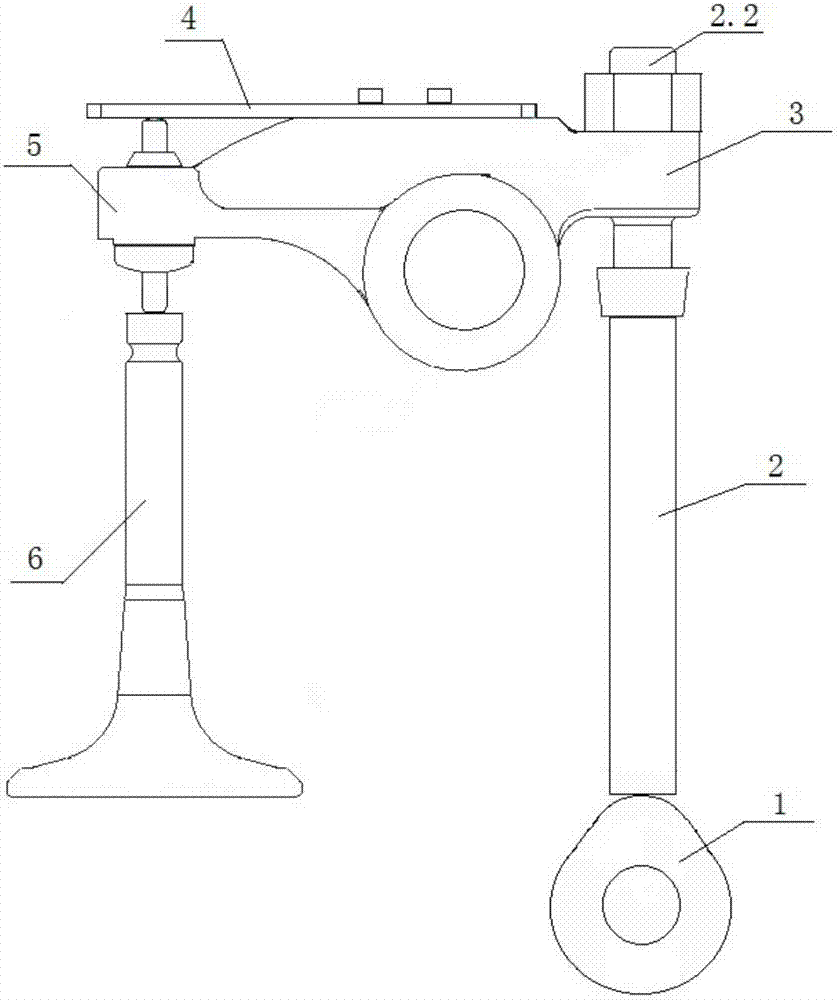

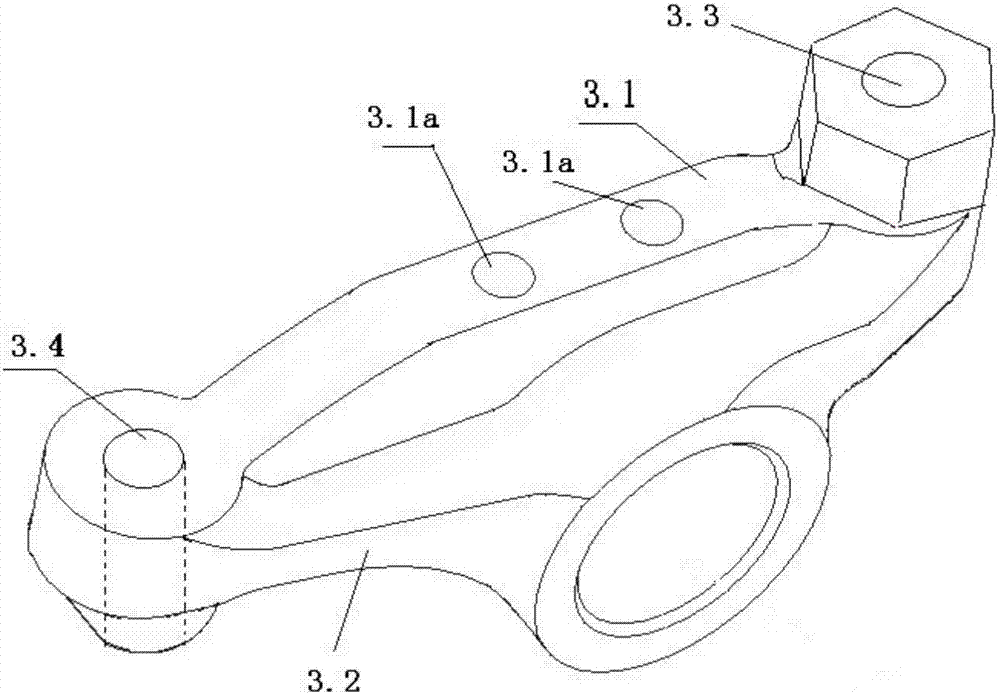

[0044] Such as Figure 1-5 Shown: an engine dynamic valve clearance signal detection device, which is installed on the engine valve train, it includes a detection rocker arm 3, the detection rocker arm 3 includes the upper horizontal arch arm 3.1 and the lower bow arm 3.2, the detection rocker arm The two ends of 3 are provided with mounting holes 3.3 and through holes 3.4 respectively; the middle section of the horizontal arch arm 3.1 is a horizontal plane 3.11, and the horizontal plane 3.11 is provided with two bolt holes 3.1a.

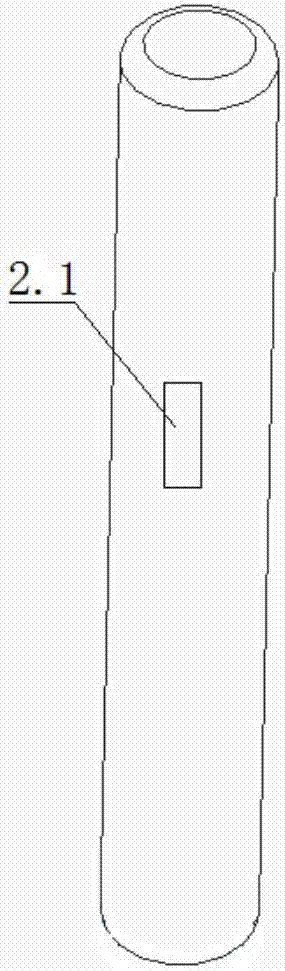

[0045] The signal trigger lifter 2 is fixed in the mounting hole 3.3 through the top bolt 2.2; the bottom surface of the signal trigger lifter 2 is provided with a cam 1, and the other end of the detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com