Ground velocity projection component error self-calibration method of ring laser angle measuring device

A self-calibration, laser technology, used in measuring devices, instruments, etc., can solve problems such as angle measurement errors, reduce errors, reduce noise, and improve product reliability and ease of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be further described:

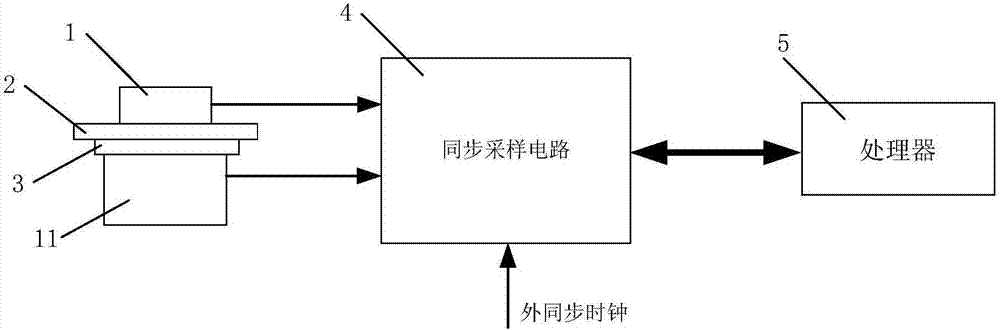

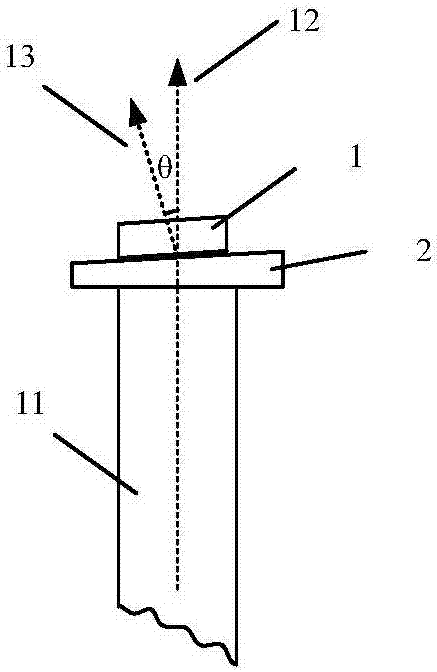

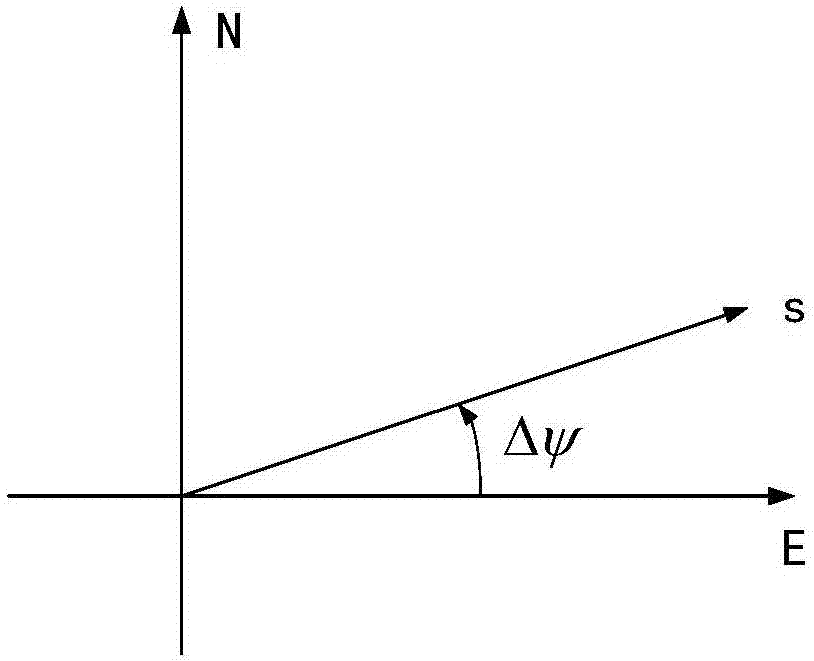

[0032] Please also see figure 1 , figure 2 , image 3 , the hardware part of the ground speed projection component error self-calibration method of the ring laser angle measuring device of the present invention includes a ring laser angle measuring device, a circular induction synchronizer, a transition plate, a synchronous sampling circuit and a processor, wherein the ring laser angle measuring device and The circular induction synchronizers are installed on both sides of the transition board respectively, and both are connected with the synchronous sampling circuit, and the synchronous sampling circuit is connected with the processor. The self-calibration method of the ground speed projection component error of the ring laser angle measuring device of the present invention adopts the least square method, and the angle information from the circular induction synchroniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com