High and low temperature transverse vibration tester for fastener

A technology of lateral vibration and fasteners, which is applied in vibration testing, testing of machine/structural components, temperature control using electric methods, etc., can solve problems such as unsatisfactory performance testing, achieve good practical performance, improve diversification, Guaranteed temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

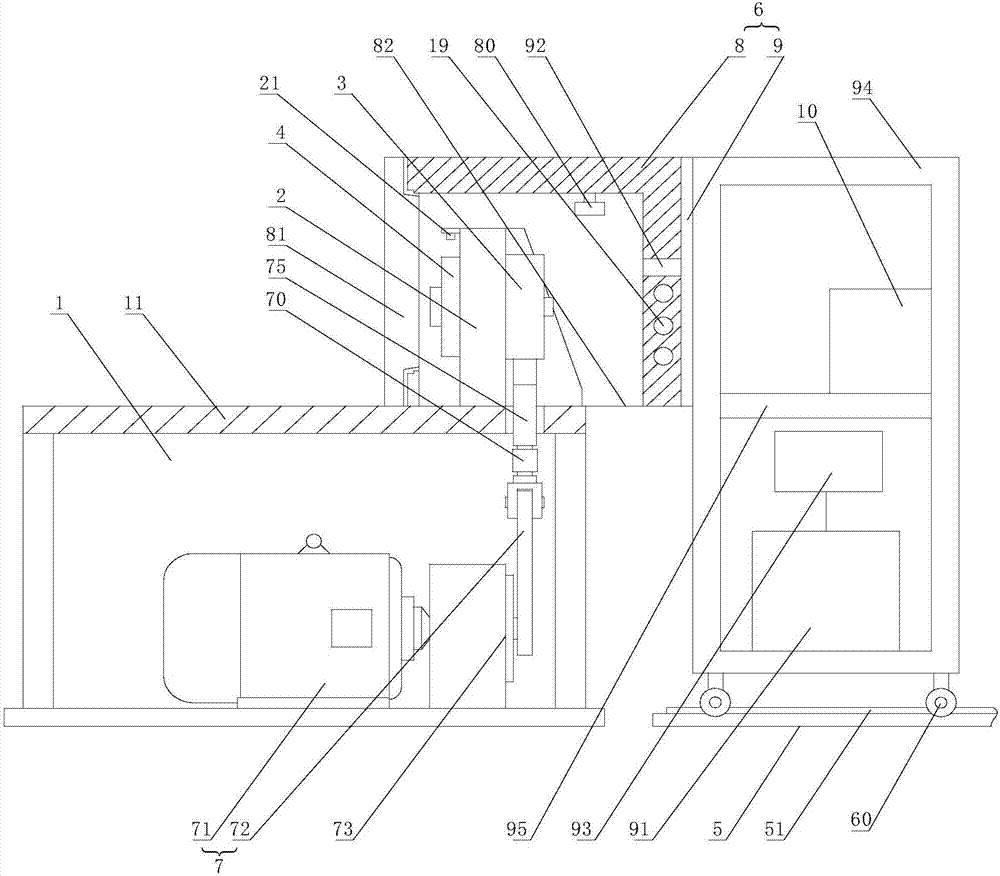

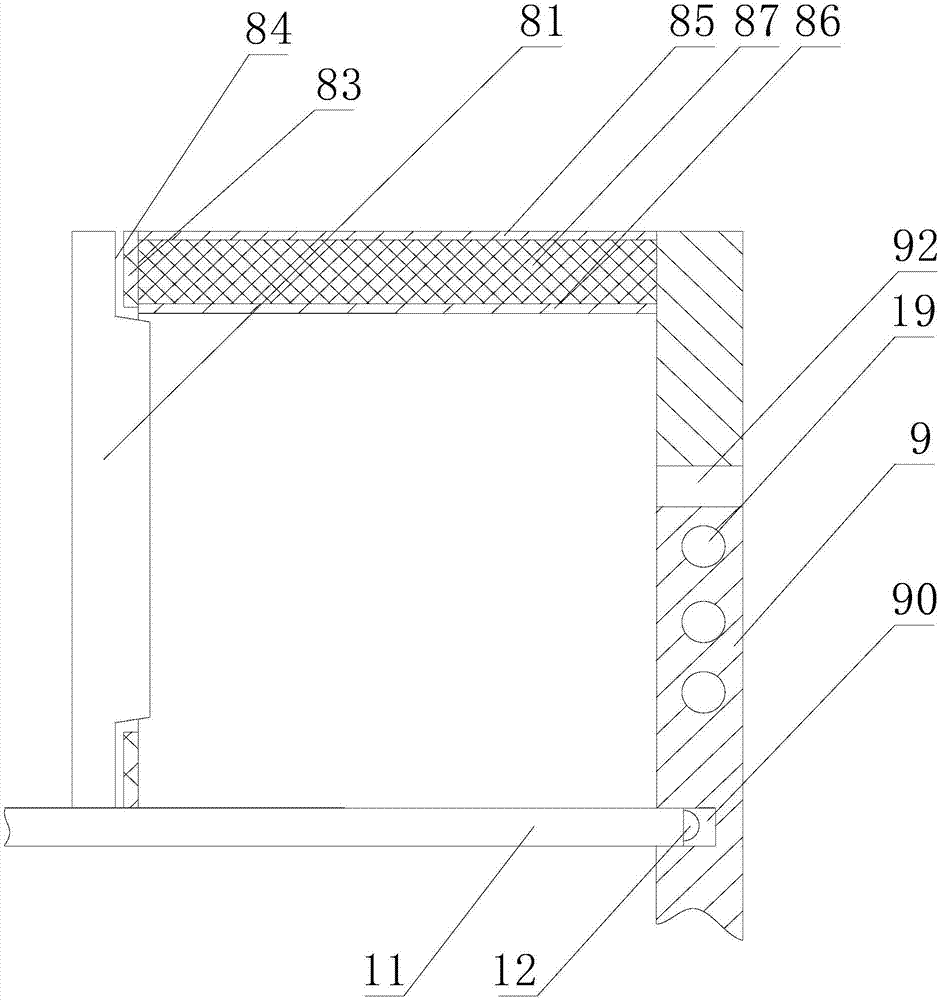

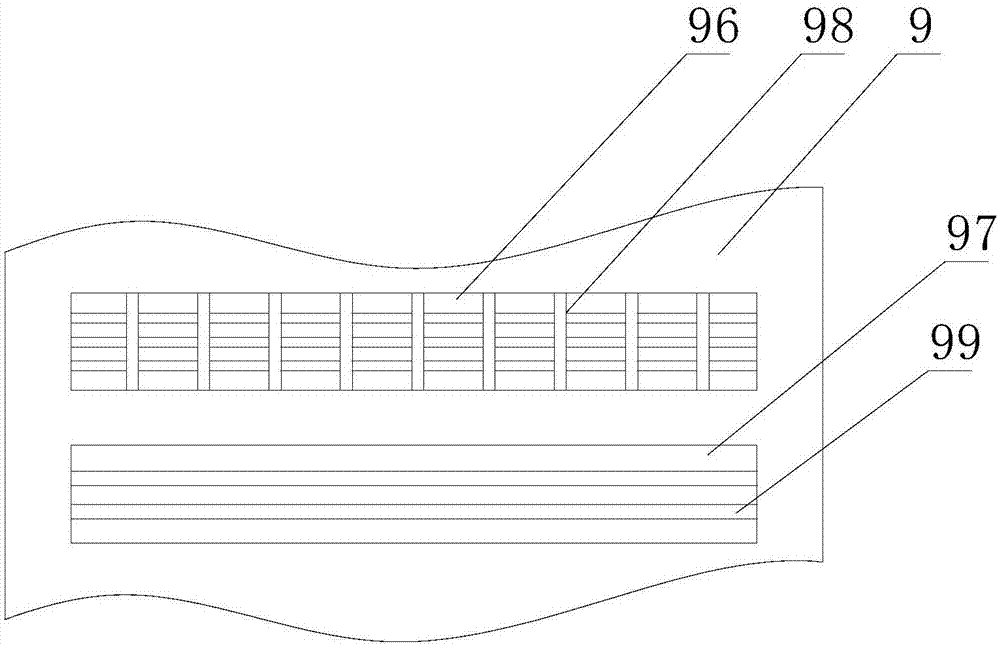

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the high and low temperature lateral vibration testing machine for fasteners includes a frame 1 and a bracket 2 arranged on the frame 1. The bracket 2 is provided with a fixture 3 for fixing the fastener to be tested. The first load cell 4 for the axial pretightening force of the fastener to be measured also includes a base 5 and a control box 6 with controllable internal temperature. The control box 6 is slidably connected to the base 5, and a drive The clamp 3 moves up and down on the support 2 with a drive assembly 7, the drive assembly 7 is provided with a second load cell 70 for detecting the lateral force of the fastener under test, and the support 2 is provided with a displacement sensor for detecting the lateral displacement of the fastener under test. Sensor 21; Control box 6 comprises working room 8 and equipment room 9, and working room 8 is arranged on the equipment room 9, and one side of work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com