Anticorrosive top-coat and preparation method thereof

A topcoat and preparation process technology, applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems not mentioned, and achieve the effect of improving multiple varieties, reducing production loss and waste, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

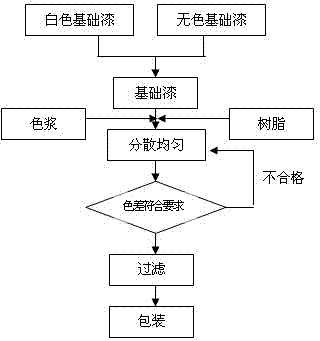

[0089] Embodiment 1: the production of 1000kg iron red alkyd topcoat

[0090] Pour 45kg of alkyd resin white base paint (Example 2) and 670kg of alkyd resin colorless base paint (Example 2) into the material tank, after stirring evenly, add 143kg of iron red paste (Example 2), chrome Yellow pulp (Example 2) 2kg, alkyd resin 100kg, after stirring evenly, add drier 40kg, disperse evenly, obtain the finished product.

Embodiment 2

[0091] Embodiment 2: the production of 1000kg white acrylic topcoat

[0092] Pour 500 kg of acrylic resin white base paint (embodiment 2) and 500 kg of acrylic resin colorless base paint (embodiment 2) into a material tank, and after dispersing evenly, a finished product is obtained.

Embodiment 3

[0093] Embodiment 3: the production of 1000kg light sky phthalein blue acrylic topcoat

[0094] Pour 380kg of acrylic resin white base paint (Example 2) and 617kg of acrylic resin colorless base paint (Example 2) into the material tank, after stirring evenly, add 1.2kg of phthalocyanine blue pulp (Example 2), chromium Yellow slurry (embodiment 2) 1.8kg, after dispersing evenly, obtains finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com