Induction cooker coil disc and processing technology thereof

A processing technology and a technology for a coil disk, applied to the field of an induction cooker coil disk and its processing technology, can solve problems such as inability to effectively control magnetic field leakage, limit induction heating efficiency, troublesome coil disk installation, etc., and achieve overall cost increase, installation process simplification, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings.

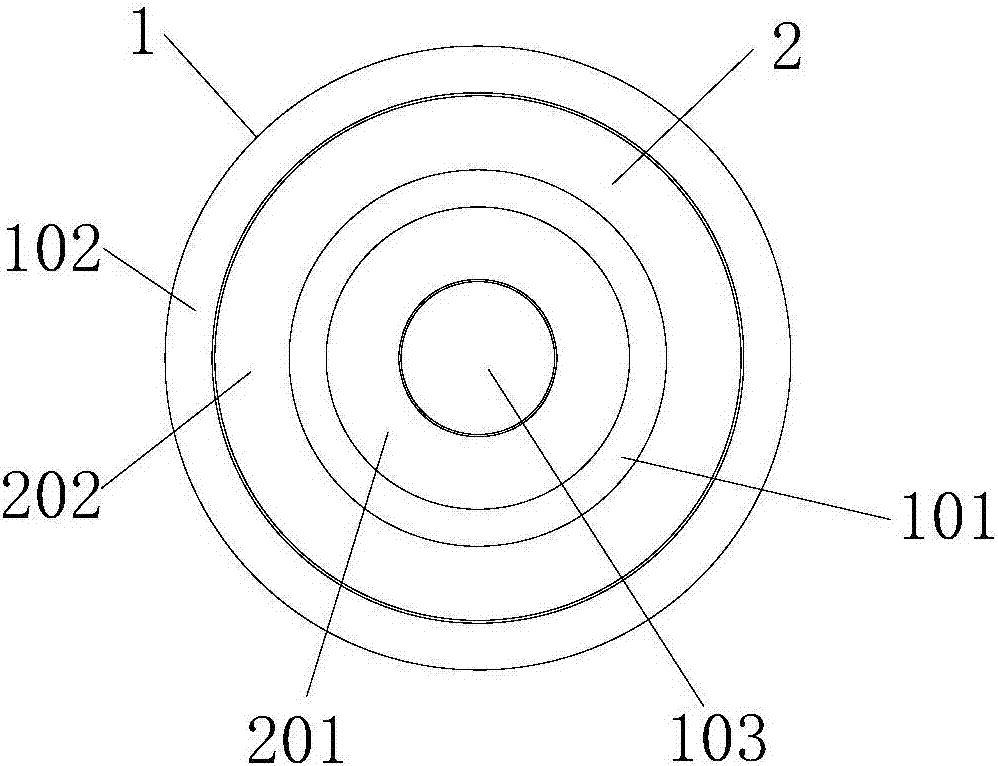

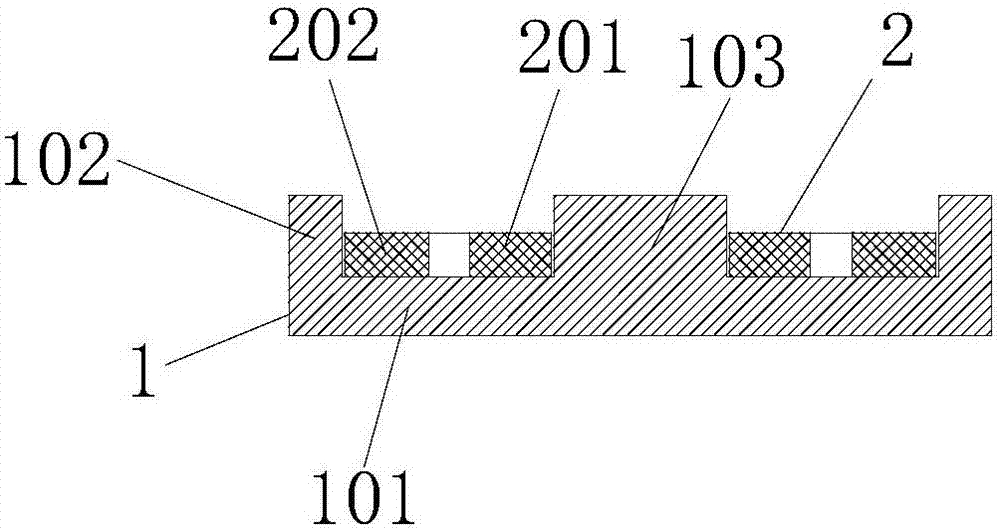

[0025] Such as Figure 1 to 2 As shown, the induction cooker coil plate includes a magnetic core frame 1 and a coil winding plate 2. The magnetic core frame 1 includes a circular chassis 101, and an upward annular flange is provided on the outer edge of the upper surface of the circular chassis 101 102. A support column 103 is provided at the center of the upper surface of the circular chassis 101, the coil winding disk 2 is sleeved on the support column 103, and the coil winding disk 2 is located between the annular flange 102 and the support column 103, so The circular chassis 101, the annular flange 102, and the support column 103 are an integrated structure, and the magnetic core frame 1 is integrally cast with magnetic materials and engineering plastics. The magnetic core frame 1 of the induction cooker coil plate is made of magnetic materials and engineering plastics. Such a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com