Engine fault prediction method

A fault prediction and engine technology, applied in the field of aerospace vehicles, can solve problems such as difficulty in finding engine fault prediction methods, different signal characteristics, etc., to achieve the effects of easy operation, improved reliability, and overcoming nonlinearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

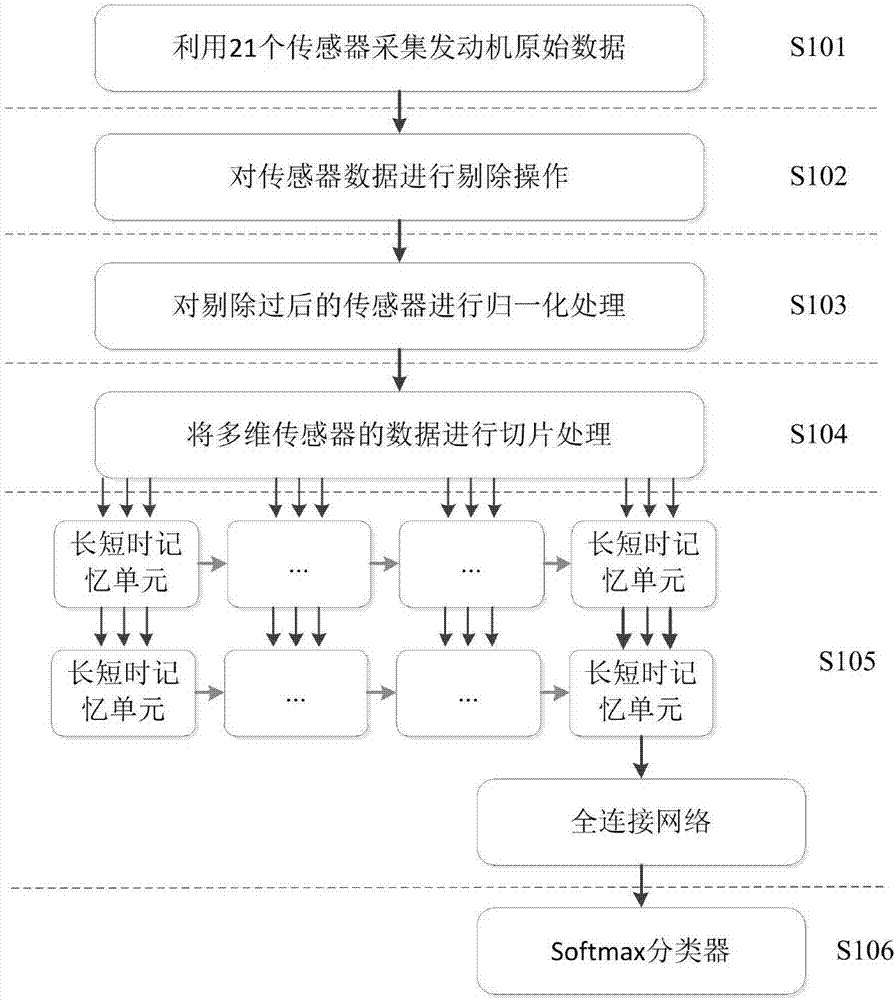

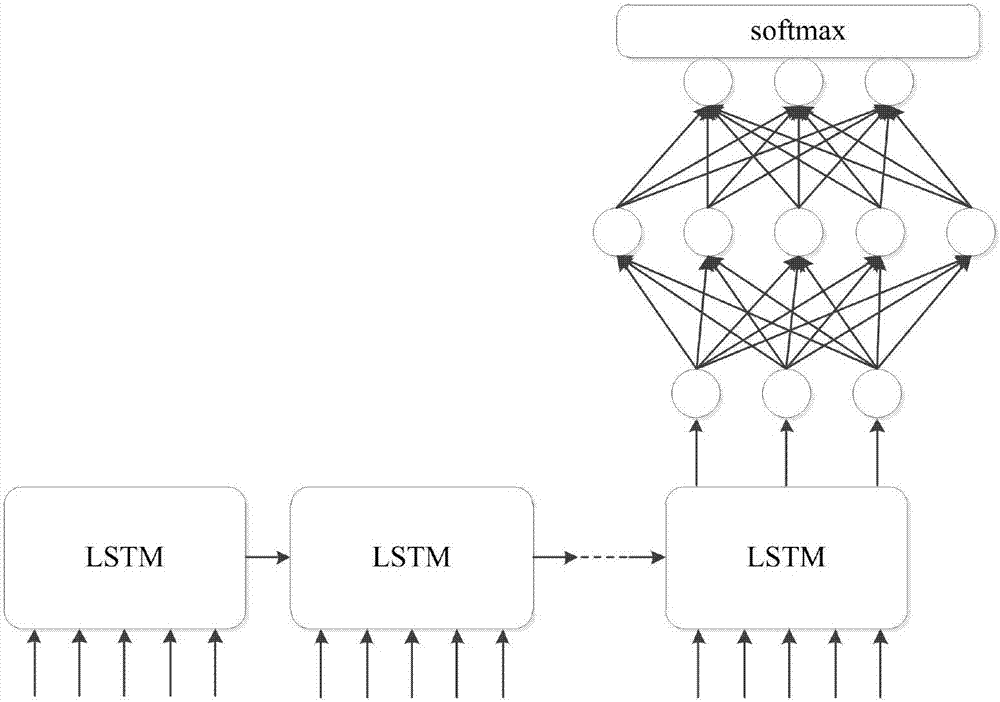

[0027] Such as figure 1 As shown, the preferred embodiment of the present invention discloses a failure prediction method of an engine, specifically for the failure prediction of a gas turbine engine, comprising the following steps:

[0028] S101: Using 21 sensors to collect raw engine data;

[0029] 21 sensors are arranged on the gas turbine engine, and the measured physical quantities are: the total temperature of the fan inlet, the total temperature of the low-pressure compressor (LPC) outlet, the total temperature of the high-pressure compressor (HPC) outlet, and the total temperature of the low-pressure turbine (LPT). ) air outlet total temperature, fan air inlet pressure, bypass duct total temperature, high pressure compressor (HPC) air outlet total pressure, physical fan speed, physical core speed, engine pressure rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com