Kitchen appliance, range hood and automatic cleaning method of range hood

An automatic cleaning and range hood technology, which is applied in the field of automatic cleaning, kitchen appliances and range hoods, can solve problems such as easy retention, failure to flow into the oil collection device, poor cleaning effect of the volute, etc., to reduce costs and improve cleaning effect , the effect of good use experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

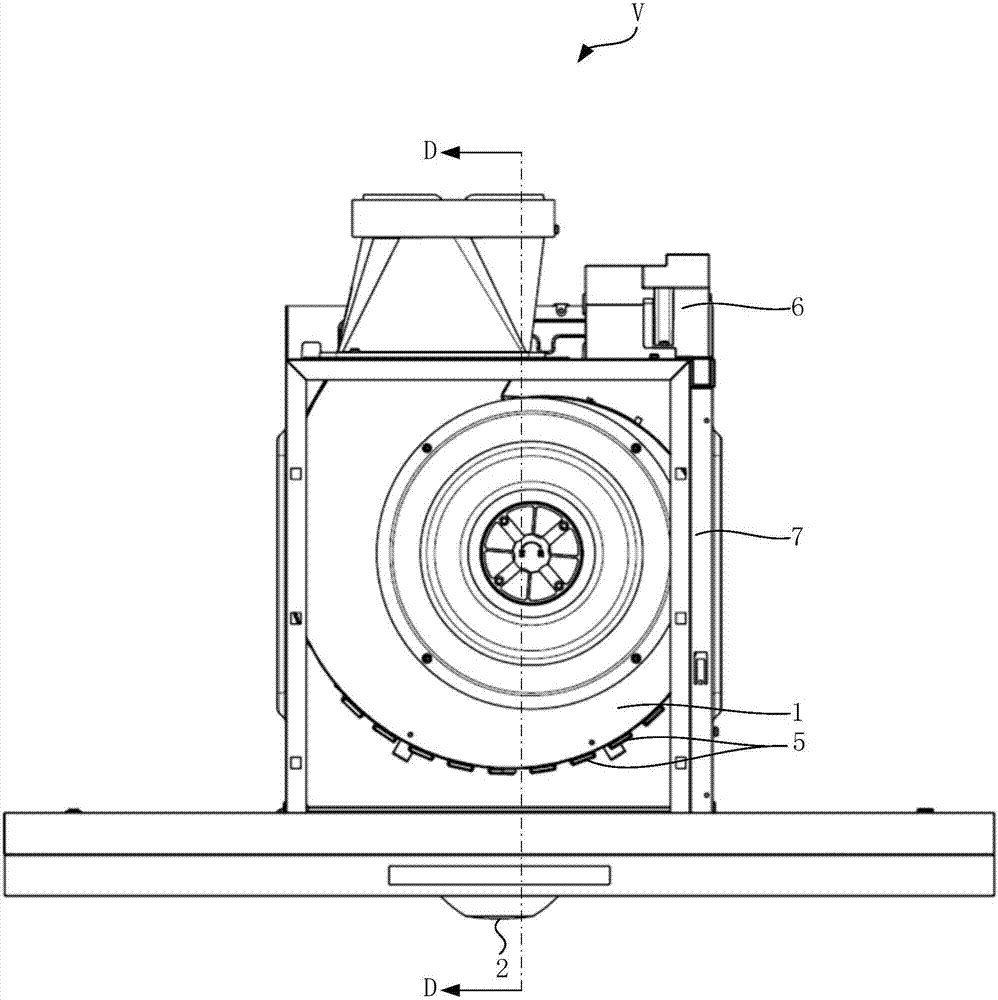

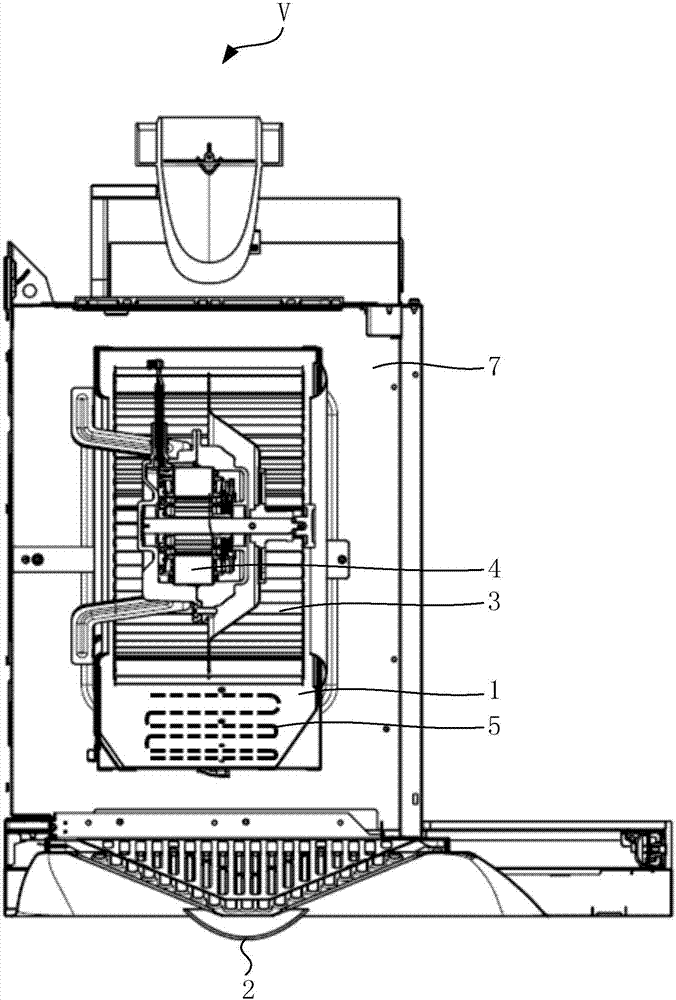

[0051] This embodiment provides an automatic cleaning method for range hoods, such as Figure 1 to Figure 2 As shown, the range hood V of this embodiment includes a volute 1 , an oil collecting device 2 for collecting grease, an impeller 3 inside the volute 1 and a motor 4 for driving the impeller 3 to rotate. When the range hood V works in the smoking mode to take away the oil fume generated in the cooking process and discharge it outside, the motor 4 drives the impeller 3 to rotate.

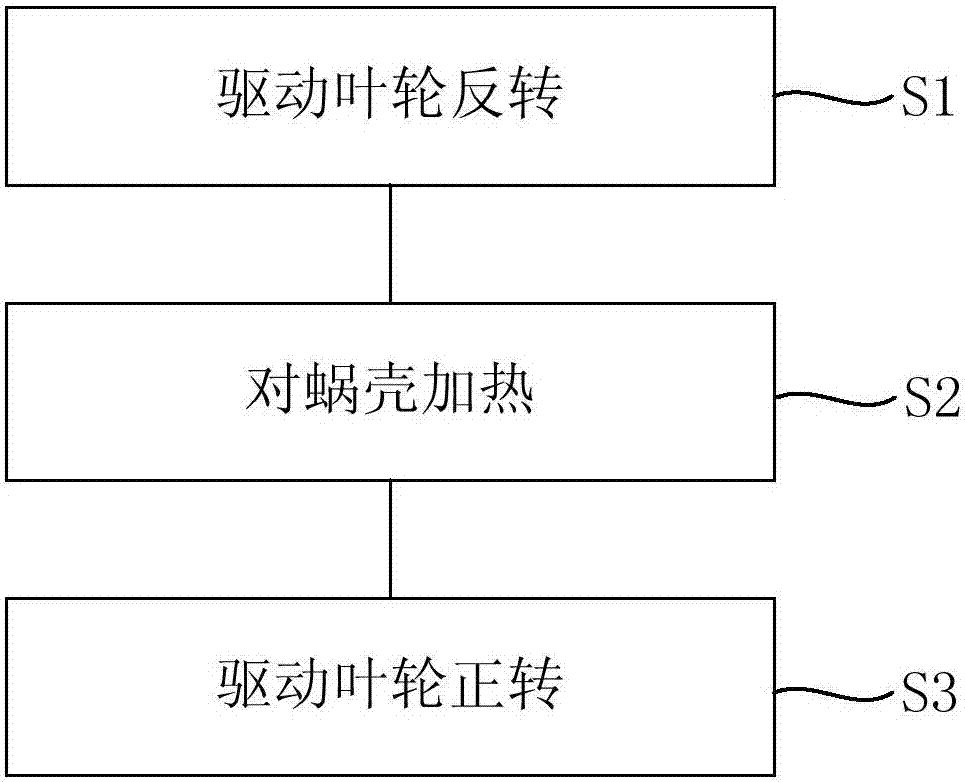

[0052] Combine below image 3 The automatic cleaning method of the range hood in this embodiment is introduced. like Figure 1 to Figure 3 As shown, the automatic cleaning method of the present embodiment includes:

[0053] Step S1: Drive the impeller 3 to reverse to throw at least part of the grease on the impeller 3 onto the volute 1. The rotation of the impeller 3 during reverse rotation is opposite to that of the range hood V in the smoking mode.

[0054] Step S2: heating the volute 1 t...

no. 2 example

[0111] The difference between the second embodiment and the first embodiment is: in the automatic cleaning method of the range hood of the second embodiment, continue to refer to Figure 1 to Figure 2 As shown, before heating the volute 1, the impeller 3 is driven to reverse A times, A is less than N; then, while the volute 1 is heated, the impeller 3 is driven to reverse B times, A+B=N, that is, the volute The starting time of heating 1 is not later than the starting time of the penultimate B reverse rotation of the impeller 3, and the stopping time of the heating of the volute 1 is not earlier than the stopping time of the last reverse rotation of the impeller 3.

[0112] In the first variation example of this embodiment, before the volute 1 is heated, the driving impeller 3 is reversed A times, A is less than N; then, after the volute 1 is heated, the driving impeller 3 is reversed C times, A+ C=N, that is, the stop moment of heating of the volute 1 is not earlier than the ...

no. 3 example

[0122] The difference between the third embodiment and the first embodiment is: in the automatic cleaning method of the range hood of the third embodiment, continue to refer to Figure 1 to Figure 2 As shown, while the volute 1 is being heated, the impeller 3 is driven to reverse B times, and B is equal to N, that is, the starting time of the volute 1 being heated is not later than the starting time of the first reverse rotation of the impeller 3, and the volute The heating of the casing 1 is stopped no earlier than the last reverse rotation of the impeller 3 .

[0123]In the technical solution of this embodiment, on the one hand, at least part of the grease on the impeller 3 will be thrown onto the volute 1 under the action of centrifugal force during the reverse rotation, thereby realizing the cleaning of the impeller 3 . On the other hand, while heating the volute 1, the impeller 3 is driven to reverse, and the remaining grease on the impeller 3 can be thrown onto the volut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com