Feature-based factory manufacturing process difference detection method

A manufacturing process and detection method technology, applied in the field of feature-based factory manufacturing process difference detection, can solve the problems of inability to find the difference of the whole process model, unreasonable process model, etc., and achieve the effect of flexible design, improved efficiency, and flexible methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

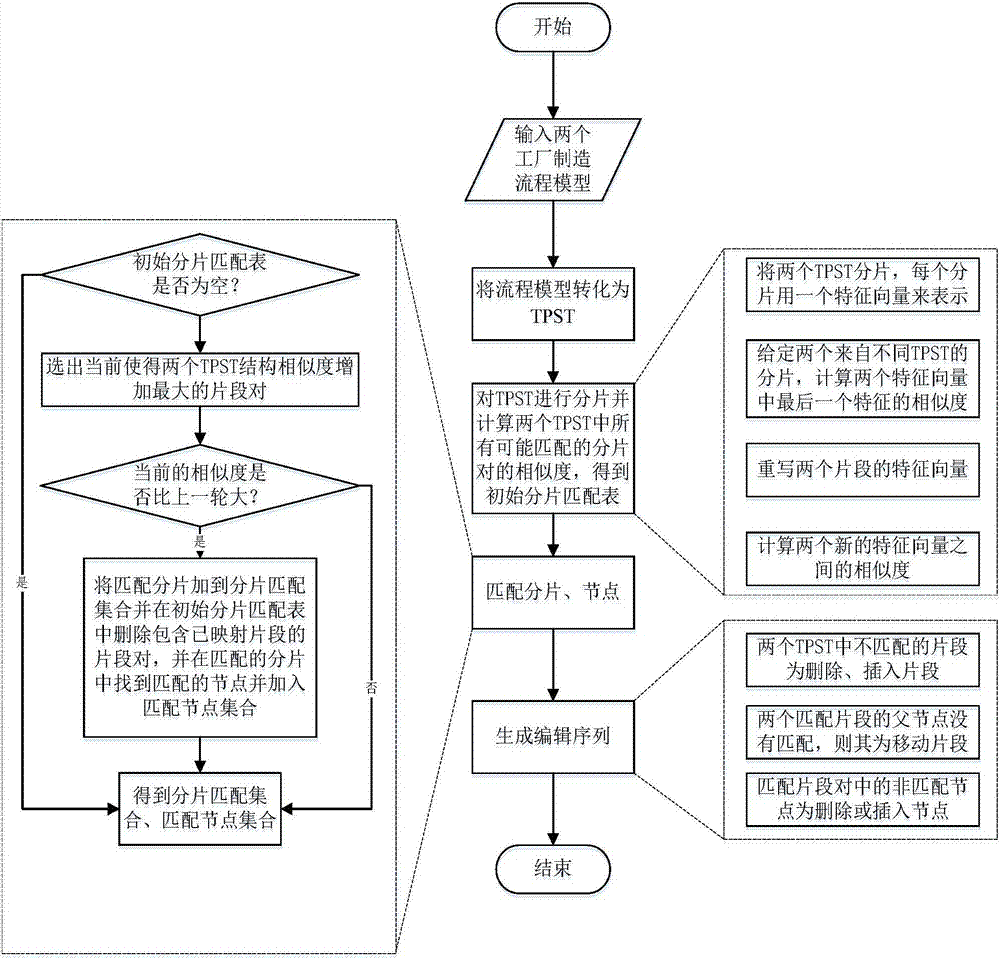

[0043] Reference attached figure 1

[0044] A feature-based method for detecting differences in factory manufacturing processes includes the following steps:

[0045] (1) Input the factory manufacturing process model of two differences to be detected;

[0046] (2) Transform the manufacturing process models of the two factories into their corresponding task-based process structure trees (task-based process structure tree, TPST);

[0047] (3) Fragment the two TPSTs respectively, and calculate the similarity of all possible matching fragment pairs in the two TPSTs, and obtain the initial fragment matching table F={(f 1 ,f 1 ’, sim 1 ),(f 2 ,f 2 ’, sim 2 ),…,(f i ,f i ’, sim i )}, only fragments of the same type can match, including:

[0048] (3.1) Fragment the two TPSTs separately, where each fragment is represented by a feature vector composed of multiple features;

[0049] (3.2) Given slices from two different TPSTs, calculate the similarity between the last features ...

Embodiment 2

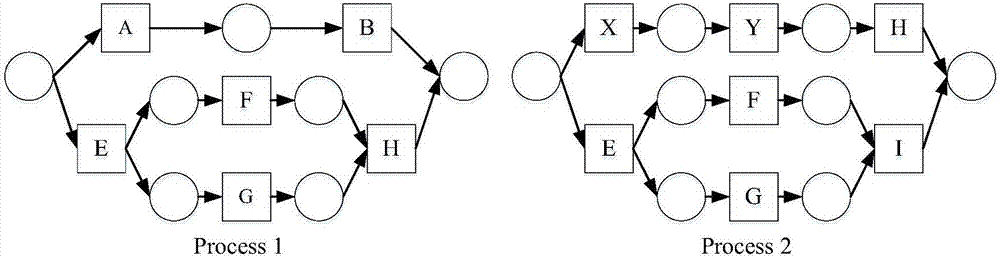

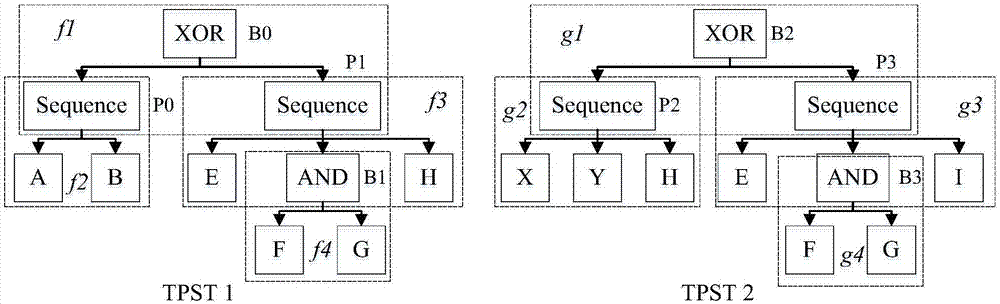

[0063] Reference attached figure 2 ,3,4,5

[0064] figure 2 Indicates two examples of factory auxiliary material processing flow model diagrams: Process 1 and Process 2. Due to the limitation of the page, letters are used to represent the meaning of task nodes: A means "finished product acceptance", B means "packaging", E means "ingredient processing", F means "cutting", G means "surface treatment", H means " Subpackage", I means "delivery to packaging department", X means "finished product inspection", Y means "coloring".

[0065] In order to get the difference between Process 1 and Process 2, we need to perform the following steps:

[0066] (1) Input two processing flow models of auxiliary materials to be detected: Process 1 and Process 2, which are modeled by Petri nets, such as figure 2 shown;

[0067] (2) Transform Process 1 and Process 2 into their corresponding task node-based process structure tree (TPST): TPST 1 、TPST 2 ,Such as image 3 As shown, each rout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com