Electric heating blowing type tobacco leaf curing room using air guide hood

A technology of air diversion and baking room, which is applied in the fields of application, tobacco, and tobacco preparation. It can solve the problems of high energy consumption, low thermal efficiency, and waste of heat energy, and achieve energy saving, thermal efficiency improvement, and convenient use and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

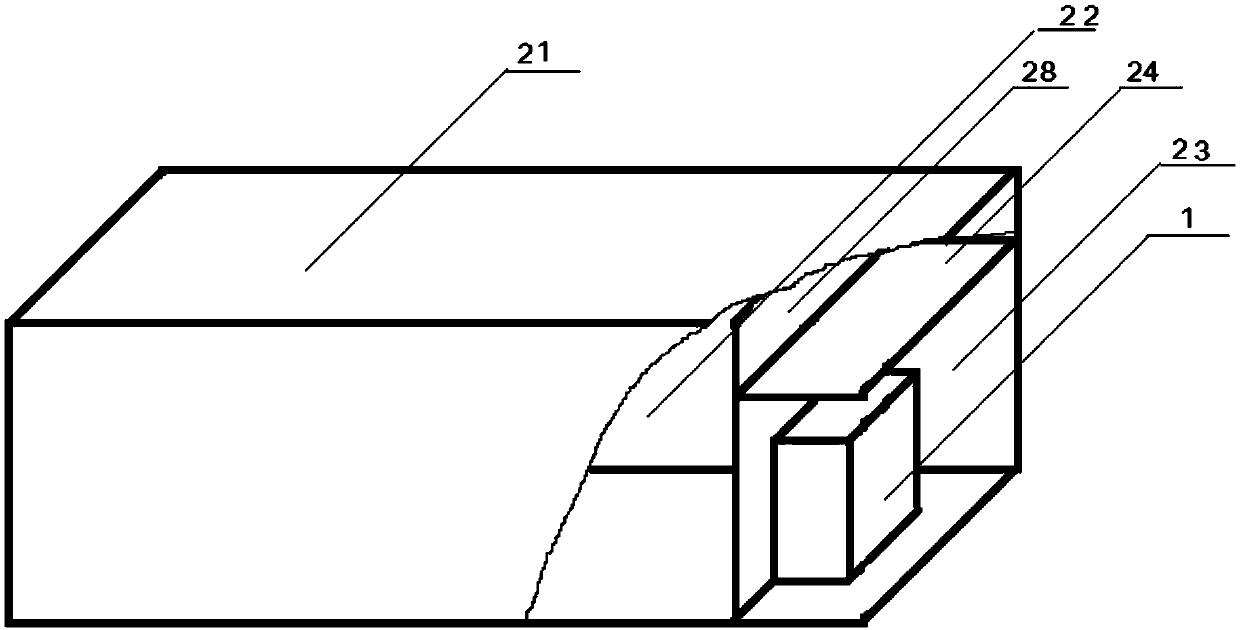

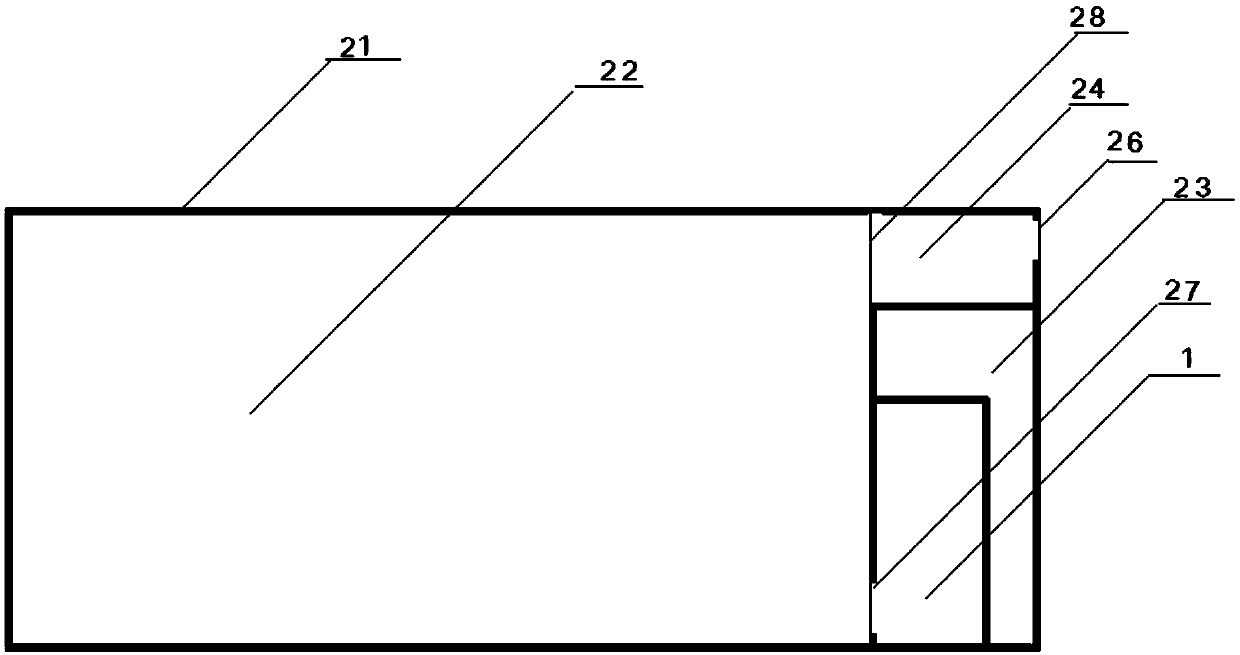

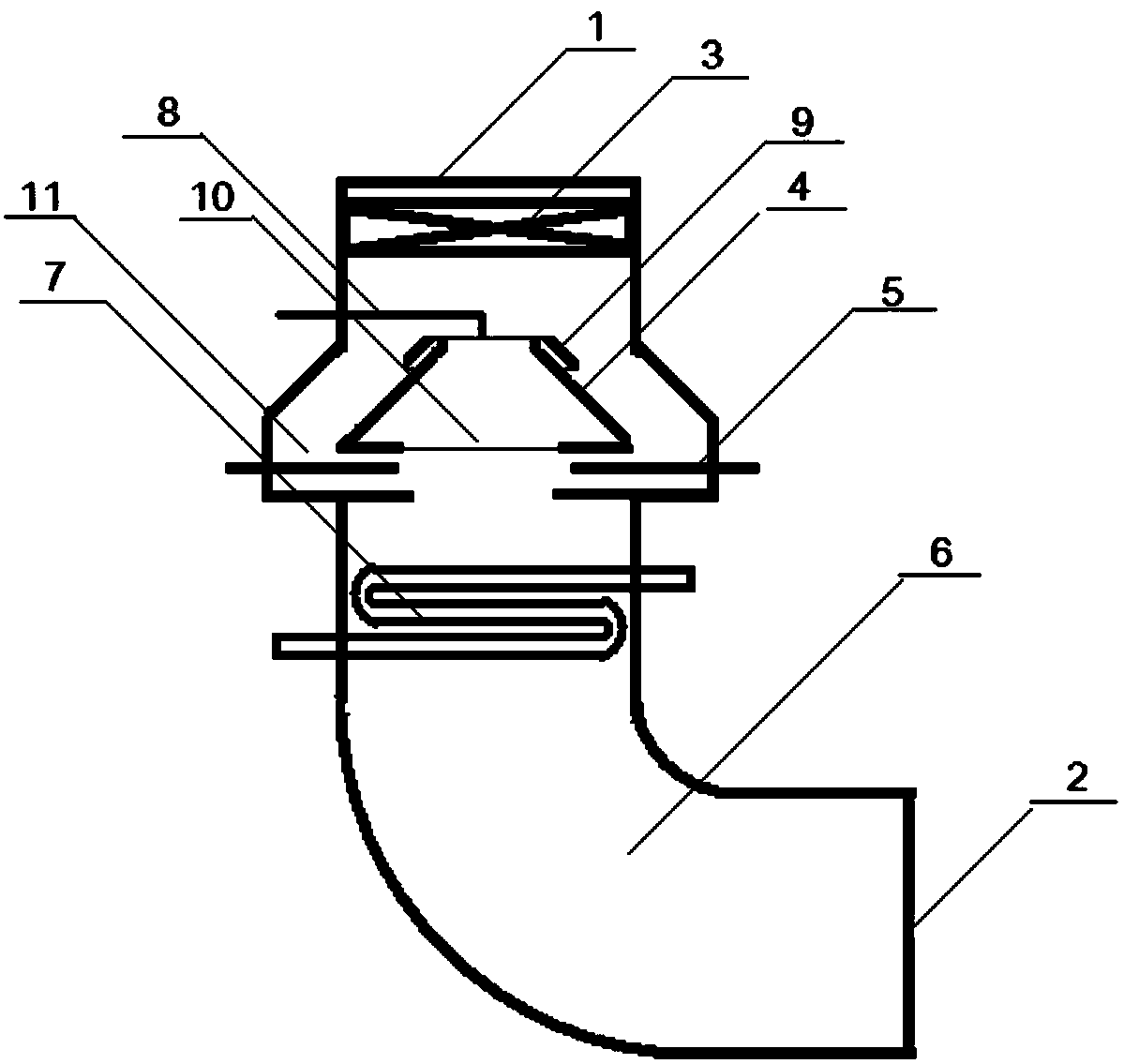

[0026] Embodiment 1: An electric heating blowing type tobacco leaf curing room using an air guide hood, which is characterized in that the curing room body 21 is divided into left and right parts by a partition wall, and the two parts are respectively provided with doors for the entry and exit of cured tobacco And the door for maintenance personnel to go in and out, one end is the baking area 22 of curing tobacco leaves, the other end is divided into upper and lower two parts, the lower part is the heating area 23, the upper part is the dehumidification area 24, between the dehumidification area 24 and the baking area 22 There is a dehumidification window 28 for dehumidification in between, and the dehumidification area 24 is also provided with a dehumidification outlet 26 for dehumidifying outward; Provide the air inlet 27 of hot blast in 22, be provided with the electric heating device that uses air guide cover in heating area 23; 4 and electric heater 5, an electric fan 3 t...

Embodiment 2

[0027] Embodiment 2: An electric heating and blowing-type tobacco leaf curing room using an air guide hood, which is characterized in that the main body 21 of the curing room is divided into left and right parts by a partition wall, and the two parts are respectively provided with doors for the entry and exit of cured tobacco And the door for maintenance personnel to go in and out, one end is the baking area 22 of curing tobacco leaves, the other end is divided into upper and lower two parts, the lower part is the heating area 23, the upper part is the dehumidification area 24, between the dehumidification area 24 and the baking area 22 There is a dehumidification window 28 for dehumidification in between, and the dehumidification area 24 is also provided with a dehumidification outlet 26 for dehumidifying outward; Provide the air inlet 27 of hot blast in 22, be provided with the electric heating device that uses air guide cover in heating area 23; 4 and electric heater 5, an ...

Embodiment 3

[0028]Embodiment 3: An electric heating and blowing-type tobacco leaf curing room using an air guide hood, which is characterized in that the main body 21 of the curing room is divided into left and right parts by a partition wall, and the two parts are respectively provided with doors for the entry and exit of cured tobacco And the door for maintenance personnel to go in and out, one end is the baking area 22 of curing tobacco leaves, the other end is divided into upper and lower two parts, the lower part is the heating area 23, the upper part is the dehumidification area 24, between the dehumidification area 24 and the baking area 22 There is a dehumidification window 28 for dehumidification in between, and the dehumidification area 24 is also provided with a dehumidification outlet 26 for dehumidifying outward; Provide the air inlet 27 of hot blast in 22, be provided with the electric heating device that uses air guide cover in heating area 23; 4 and electric heater 5, an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com