A kind of forging method of machining blank of bearing housing of scroll compressor

A technology for scroll compressors and bearing seats, which is applied in the field of metal plastic forming, can solve the problems of complex shape of aluminum alloy bearing seats, insufficient filling of ribs, and easy tearing of the side wall of the flower plate, etc., so as to achieve less subsequent processing allowance, The effect of small machining allowance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

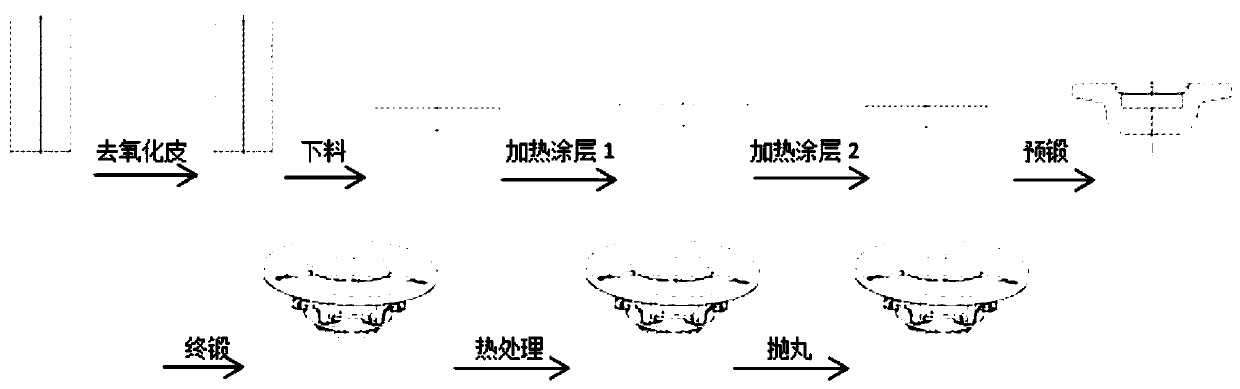

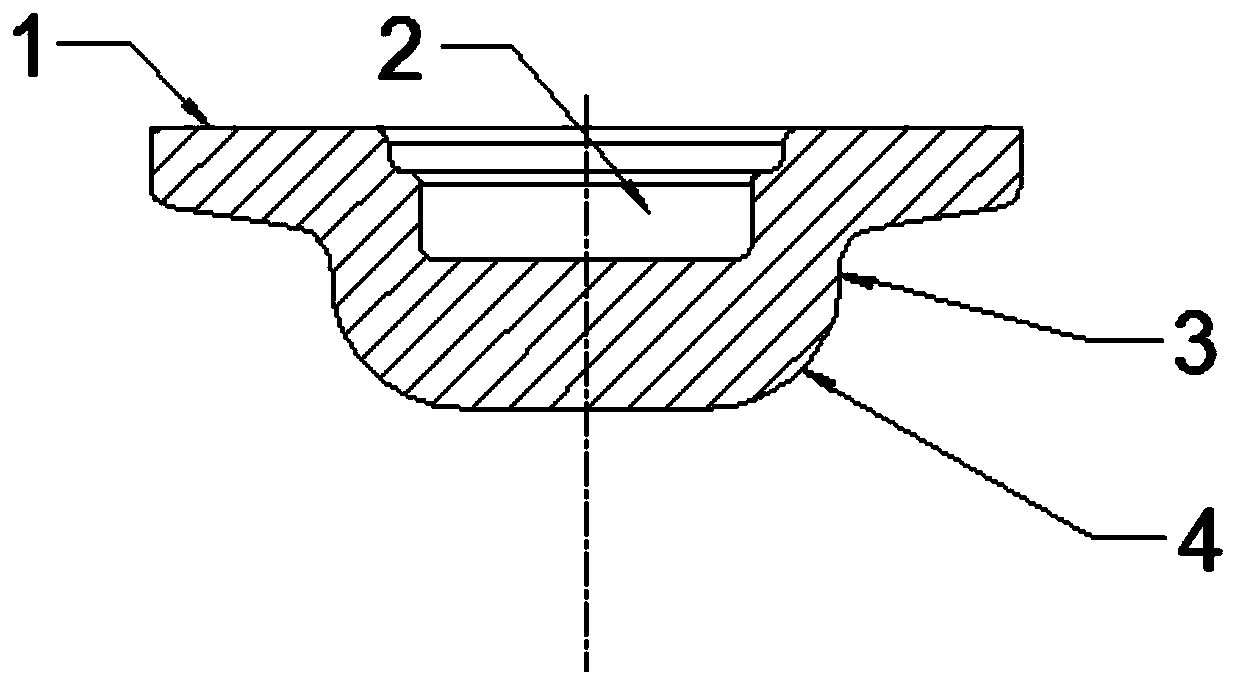

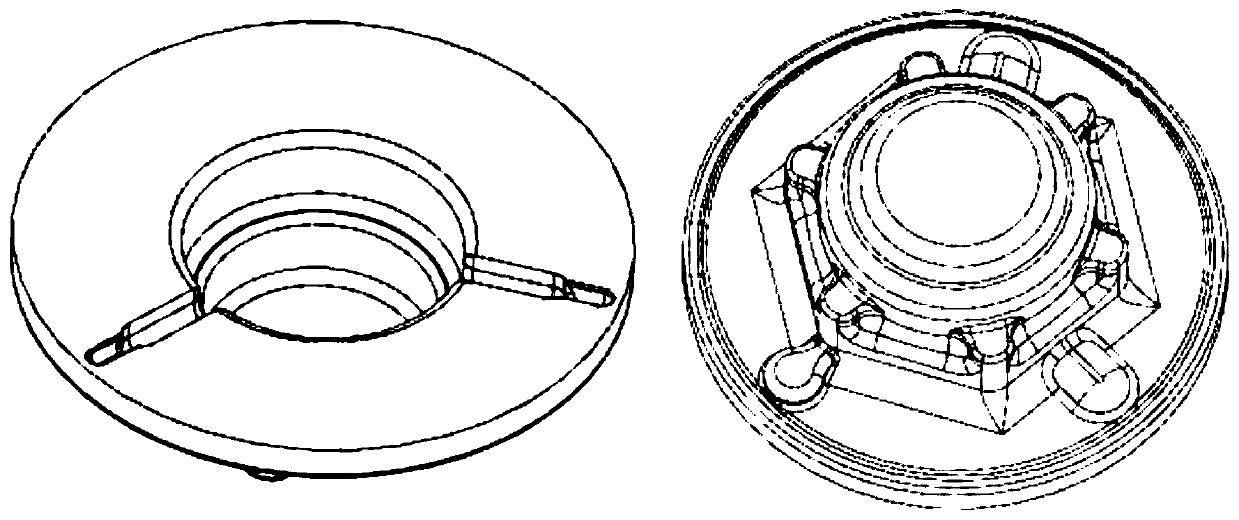

[0026] The invention provides a forging method for a machining blank of a bearing seat of a scroll compressor, as shown in the figure, it includes the following steps:

[0027] 1) For descaling, use 4032 aluminum alloy extruded rods with a specification of φ100, and the descaling depth of the outer circle of the turning bar is 1.5-2mm;

[0028] 2) Blanking, sawing machine cutting, according to the post-processing allowance requirements of the product and the principle of constant volume, the thickness of the material is 14-15mm, and the upper and lower deviation is 0.1mm;

[0029] 3) Heat coating 1, heat the tablet to 200±20°C, hang it into the graphite water diluted 20-23 times with tap water and stir it evenly, after staying for 4-6s, stay in the air for 10-15s, put it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com