Cassegrain primary mirror precision machining method and auxiliary fixture thereof

A precision machining and fixture technology, applied in the field of Cassegrain primary mirror precision machining method and its supporting fixtures, can solve the problem of insufficient mirror polishing accuracy, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

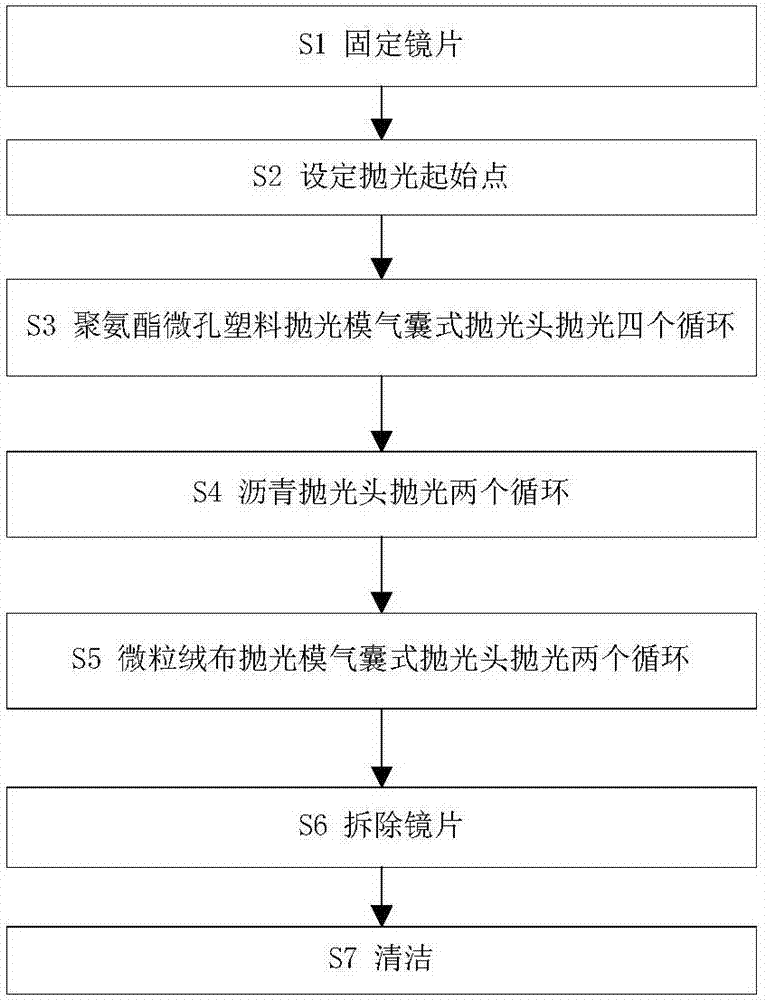

[0036] according to figure 1 A Cassegrain primary mirror precision machining method is shown, using a seven-axis polishing machine to polish the lens, and the process steps of the processing method are:

[0037] S1 Fix the rough-processed lens on the polishing jig, and fix the polishing jig on the working table of the seven-axis polishing machine tool;

[0038] S2 Use the dial indicator to rotate the center position of the lens, and locate the starting point of the polishing program of the seven-axis polishing machine through this center position;

[0039] S3 installs the polyurethane microporous plastic polishing mold airbag polishing head on the seven-axis polishing machine tool, and controls the seven-axis polishing machine tool through the polishing program to make the polishing head grind the mirror surface; the mold layer thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com