Novel stainless steel composite plate

A technology of stainless steel and composite panels, applied in lamination, layered products, metal layered products, etc., can solve the problems of strength, corrosion, and thermal conductivity that cannot meet the needs of the market, and achieve light weight, improved production efficiency, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

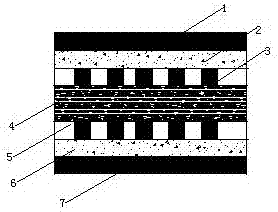

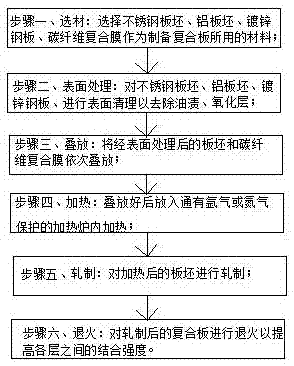

[0029] combine figure 1 , figure 2 , a new type of stainless steel clad plate provided in this embodiment, the stainless steel clad plate includes seven layers, the thickness of the novel stainless steel clad plate is 2.9mm, from top to bottom are the first layer 1, the second layer 2, The third layer 3, the fourth layer 4, the fifth layer 5, the sixth layer 6, and the seventh layer 7, the first layer 1 is a stainless steel panel, the second layer 2 is a carbon fiber composite film, and the third layer Layer 3 is a galvanized steel plate, the fourth layer 4 is a hot-dip aluminum substrate, the fifth layer 5 is a galvanized steel plate, the sixth layer 6 is a carbon fiber composite film, and the seventh layer 7 is a stainless steel panel , the first layer 1 is a stainless steel panel, the second layer 2 is a carbon fiber composite film, the third layer 3 is a galvanized steel plate, the fourth layer 4 is a hot-dip aluminum substrate, and the fifth layer 5 is a galvanized ste...

Embodiment 2

[0039] combine figure 1 , figure 2 , a new type of stainless steel clad plate provided in this embodiment, the stainless steel clad plate includes seven layers, the thickness of the novel stainless steel clad plate is 1.2mm, and from top to bottom are the first layer 1, the second layer 2, The third layer 3, the fourth layer 4, the fifth layer 5, the sixth layer 6, and the seventh layer 7, the first layer 1 is a stainless steel panel, the second layer 2 is a carbon fiber composite film, and the third layer Layer 3 is a galvanized steel plate, the fourth layer 4 is a hot-dip aluminum substrate, the fifth layer 5 is a galvanized steel plate, the sixth layer 6 is a carbon fiber composite film, and the seventh layer 7 is a stainless steel panel , the first layer 1 is a stainless steel panel, the second layer 2 is a carbon fiber composite film, the third layer 3 is a galvanized steel plate, the fourth layer 4 is a hot-dip aluminum substrate, and the fifth layer 5 is a galvanized...

Embodiment 3

[0049] combine figure 1 , figure 2 , a novel stainless steel clad plate provided in this embodiment, the clad stainless steel plate comprises seven layers, the thickness of the novel clad stainless steel plate is 1.9mm, and the order from top to bottom is the first layer 1, the second layer 2, The third layer 3, the fourth layer 4, the fifth layer 5, the sixth layer 6, and the seventh layer 7, the first layer 1 is a stainless steel panel, the second layer 2 is a carbon fiber composite film, and the third layer Layer 3 is a galvanized steel plate, the fourth layer 4 is a hot-dip aluminum substrate, the fifth layer 5 is a galvanized steel plate, the sixth layer 6 is a carbon fiber composite film, and the seventh layer 7 is a stainless steel panel , the first layer 1 is a stainless steel panel, the second layer 2 is a carbon fiber composite film, the third layer 3 is a galvanized steel plate, the fourth layer 4 is a hot-dip aluminum substrate, and the fifth layer 5 is a galvan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com