Transfer trolley for cloth during textile printing and dyeing

A transfer trolley, textile printing and dyeing technology, applied in the directions of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of high labor intensity, heavy plastic baskets, inconvenience, etc., to reduce labor intensity, convenient and fast transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

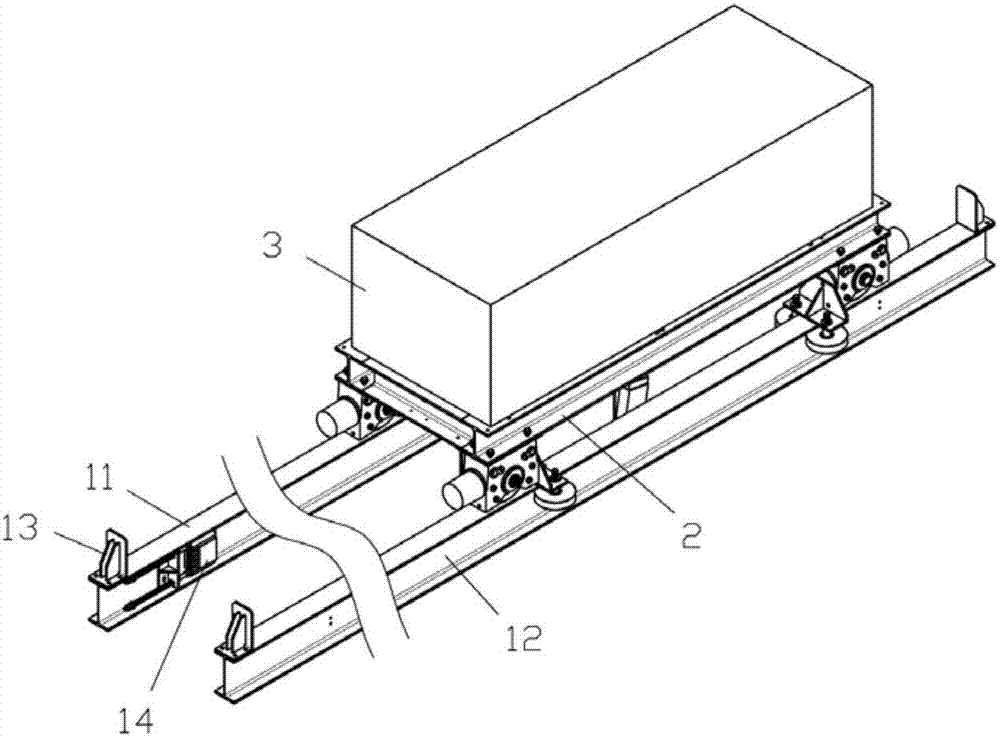

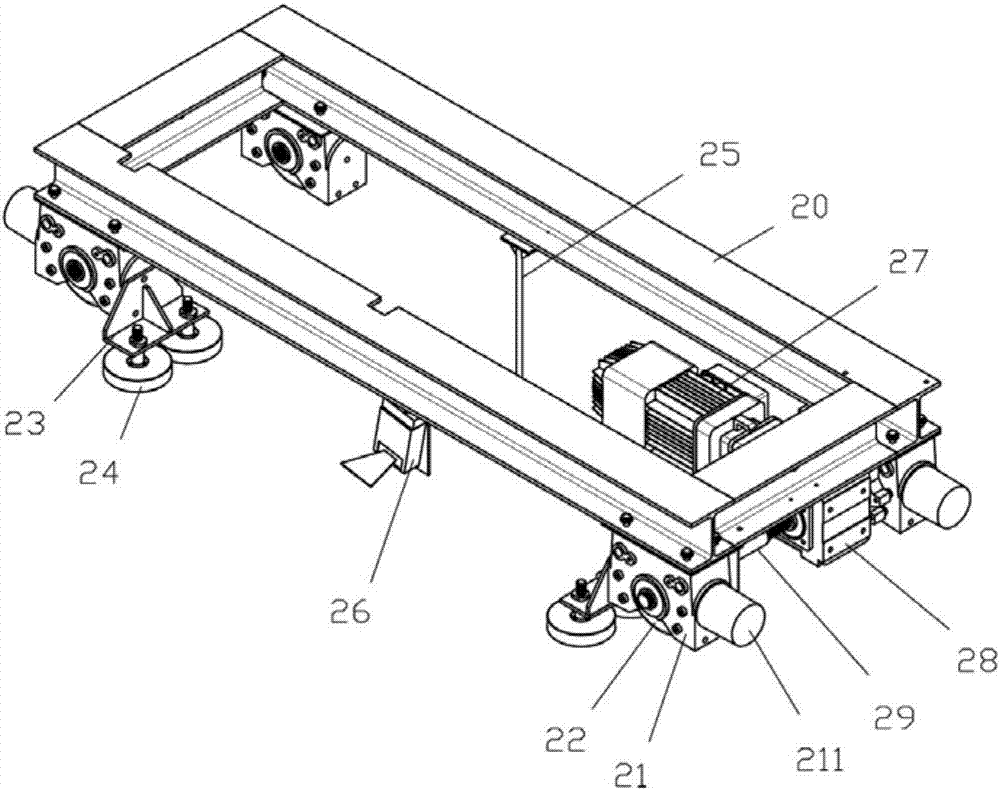

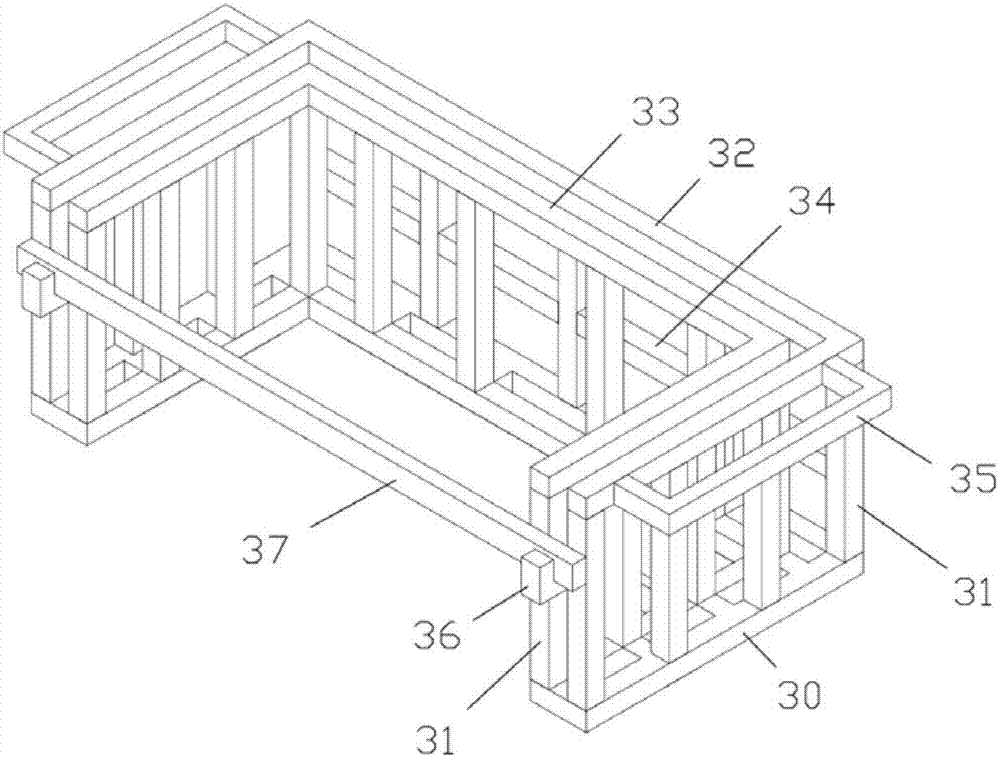

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 1-3 As shown, a transfer trolley for textile printing and dyeing cloth includes a first track 11 and a second track 12 arranged in the printing and dyeing workshop, and a trolley 2 runs on the first track 11 and the second track 12, and the upper part of the trolley 2 Lifting is provided with the framework 3 that loads plastic basket; Dolly 2 comprises square vehicle frame 20, and the bottom four corners of square vehicle frame 20 are fixed with wheel frame 21, and wheel frame 21 is rotated and is provided with walking wheel 22, and the side of wheel frame 21 is also fixed with Guide wheel frame 23, two guide wheels 24 are fixed on the guide wheel frame 23, and the rotation axis of guide wheel 24 is perpendicular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com