Water purification equipment

A water purification and equipment technology, applied in water/sewage treatment equipment, water pollutants, multi-stage water treatment, etc., can solve problems such as increased power consumption, secondary pollution, excessive bacteria in effluent, and prevent excessive dust accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

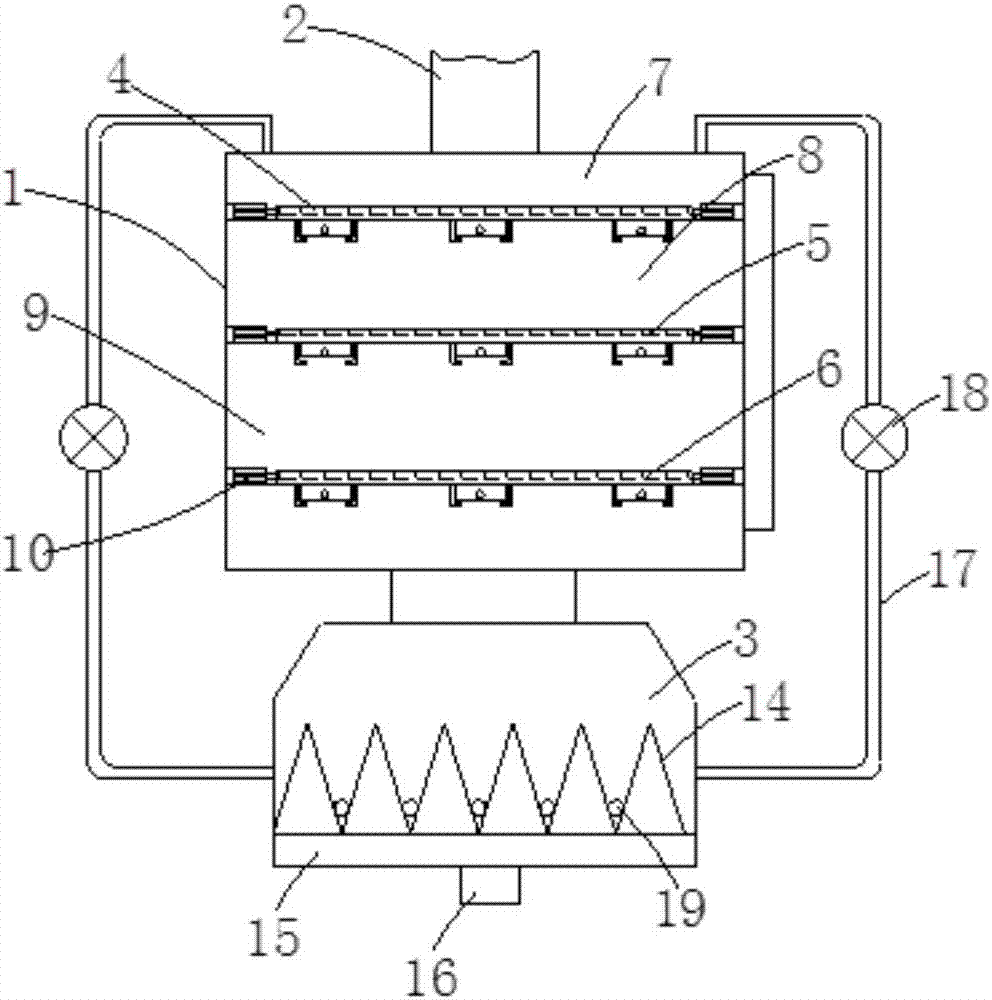

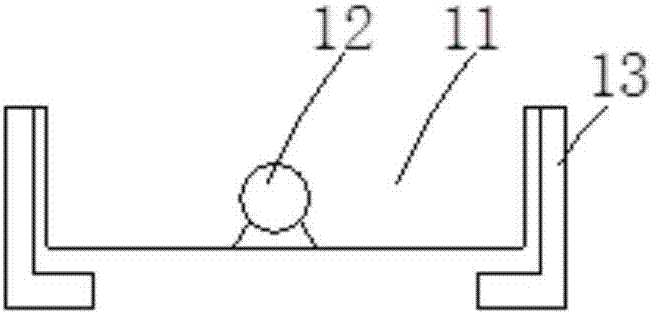

[0019] Such as figure 1 , figure 2 As shown, a kind of water purification equipment comprises a filter barrel 1, the top of the filter barrel 1 is connected to the water inlet 2, the bottom of the filter barrel 1 is connected to the water outlet storage tank 3, and the filter barrel 1 is provided with a first filter net 4, a second The filter screen 5 and the third filter screen 6, the first filter screen 4 and the top of the filter barrel 1 form the first filter cavity 7, the second filter cavity 8 is formed between the first filter screen 4 and the second filter screen 5, the second A third filter cavity 9 is formed between the filter screen 5 and the third filter screen 6, the first filter cavity 7 is filled with activated carbon particles, the second filter cavity 8 is filled with nanosphere particles, and the third filter cavity 9 is filled with high polyiodine resin Particles, the first filter screen 4, the two ends of the second filter screen 5 and the third filter sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com