Platinum channel flow control system

A platinum channel and flow control technology, used in manufacturing tools, glass manufacturing equipment, glass furnace equipment, etc., can solve the problems of multi-platinum, increased investment, restricting the length of the platinum channel flow control loop and the number of loops, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

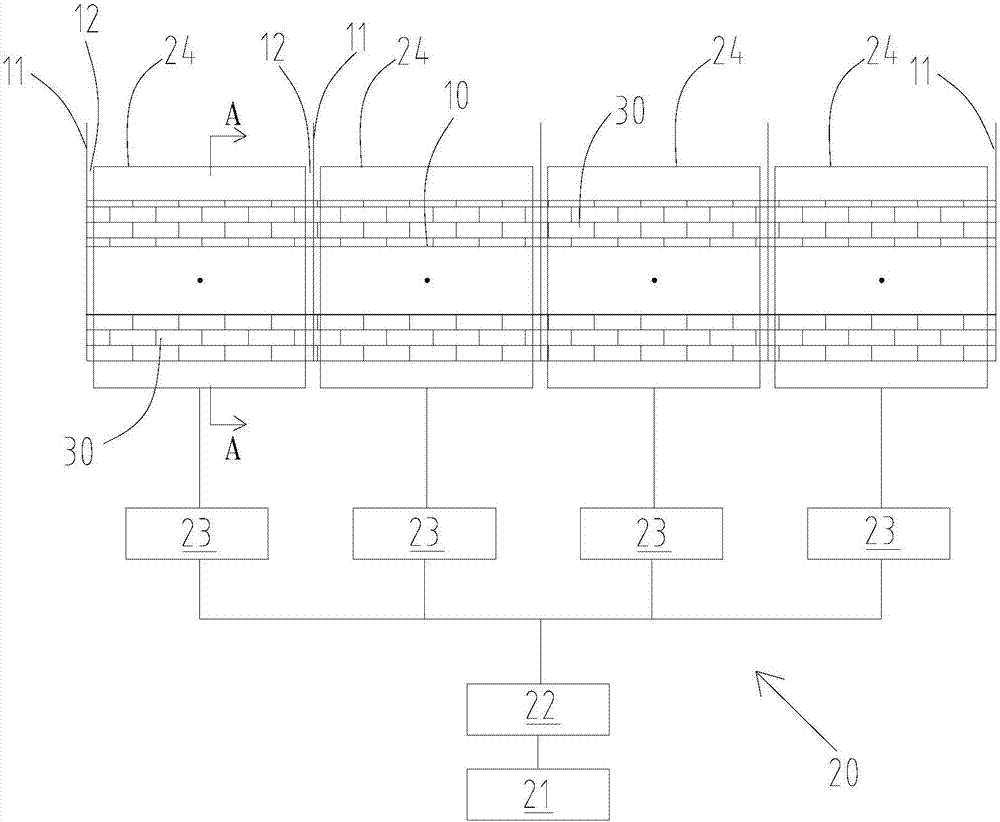

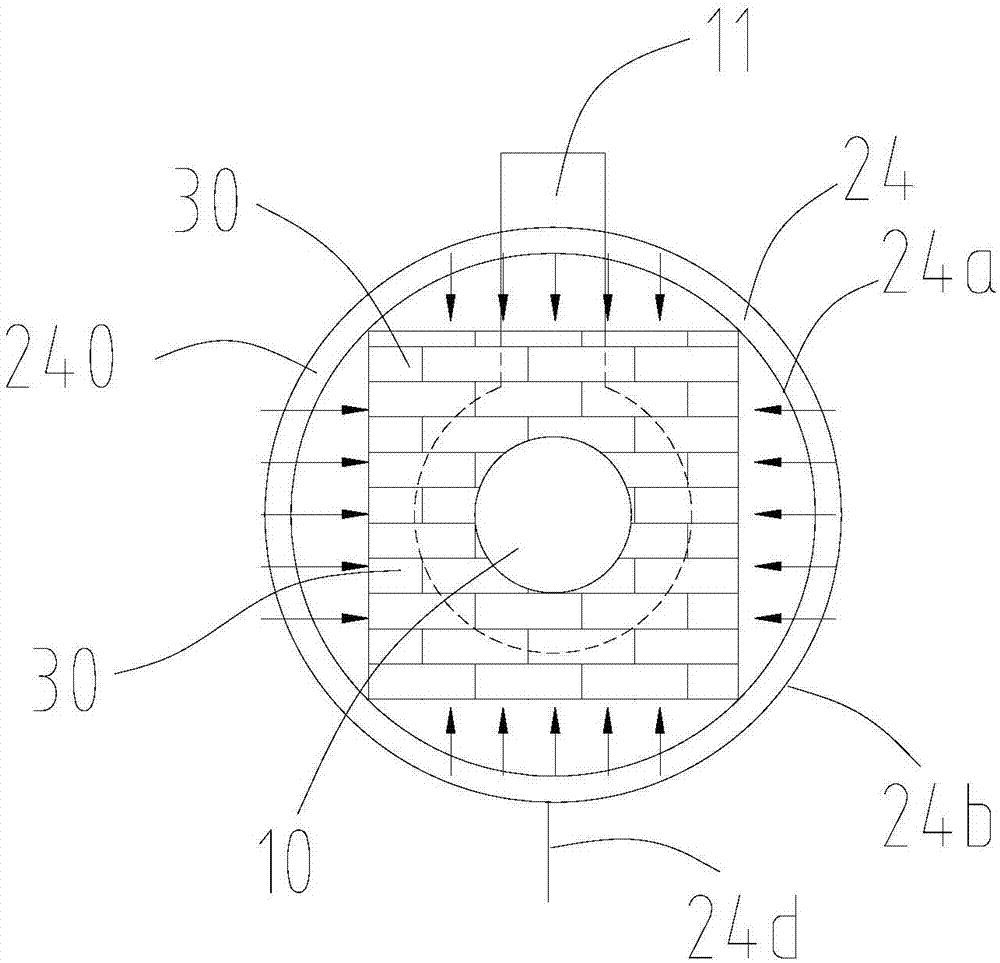

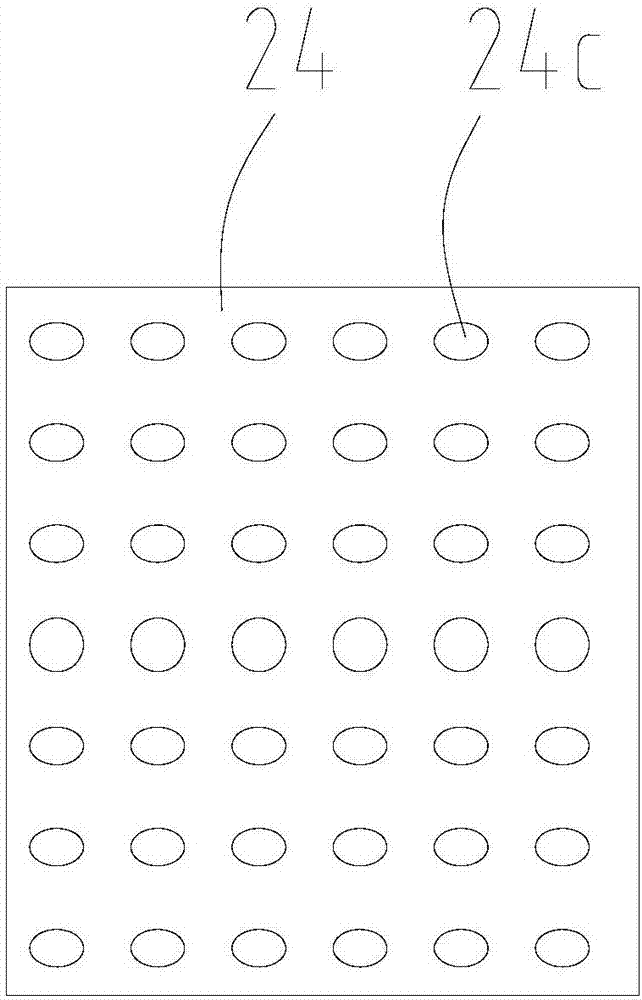

[0061] use Figure 1 to Figure 4 In the platinum channel flow control system shown, the heating regulation loop includes 4 control loops (loop 1, loop 2, loop 3, and loop 4 from the left to the right of the drawing). The gas supplied by the heat-absorbing medium supply device 21 is a mixed gas of air and water vapor. The gas temperature is adjusted to 90°C and the humidity is 60%. The liquid flow rate is 400kg / h, and the thickness of the glass plate is 0.5mm. The sleeve inner wall 24a of the outlet sleeve 24 is 150mm away from the outer surface of the platinum channel. The air outlet 24c of the air outlet sleeve 24 is circular in shape, and the area of each air outlet 24c is 76mm 2 .

experiment example 2

[0063] use Figure 1 to Figure 4 In the platinum channel flow control system shown, the heating regulation loop includes 4 control loops (loop 1, loop 2, loop 3, and loop 4 from the left to the right of the drawing). The gas supplied by the heat-absorbing medium supply device 21 is a mixed gas of air and water vapor. The gas temperature is adjusted to 100°C and the humidity is 60%. The liquid flow rate is 400kg / h, and the thickness of the glass plate is 0.5mm. The sleeve inner wall 24a of the outlet sleeve 24 is 180mm away from the outer surface of the platinum channel. The air outlet 24c of the air outlet sleeve 24 is circular in shape, and the area of each air outlet 24c is 60mm 2 .

experiment example 3

[0065] use Figure 4 and Figure 5In the platinum channel flow control system shown, the heating regulation loop includes 4 control loops (loop 1, loop 2, loop 3, and loop 4 from the left to the right of the drawing). The gas supplied by the heat-absorbing medium supply device 21 is a mixed gas of air and water vapor. The gas temperature is adjusted to 120°C and the humidity is 70%. The liquid flow rate is 400kg / h, and the thickness of the glass plate is 0.5mm. The sleeve inner wall 24a of the outlet sleeve 24 is 150mm away from the outer surface of the platinum channel. The air outlet 24c of the air outlet sleeve 24 is circular in shape, and the area of each air outlet 24c is 60mm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com