Distributed optical fiber sensing technology and system for earth-rock dam seepage line monitoring

A technology of distributed optical fiber and dipping line, which is applied in the direction of liquid level indicator for physical variable measurement, can solve problems such as interference with construction, increased temperature effect error, and unsatisfactory accuracy, and achieve the effect of strengthening anti-seepage ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

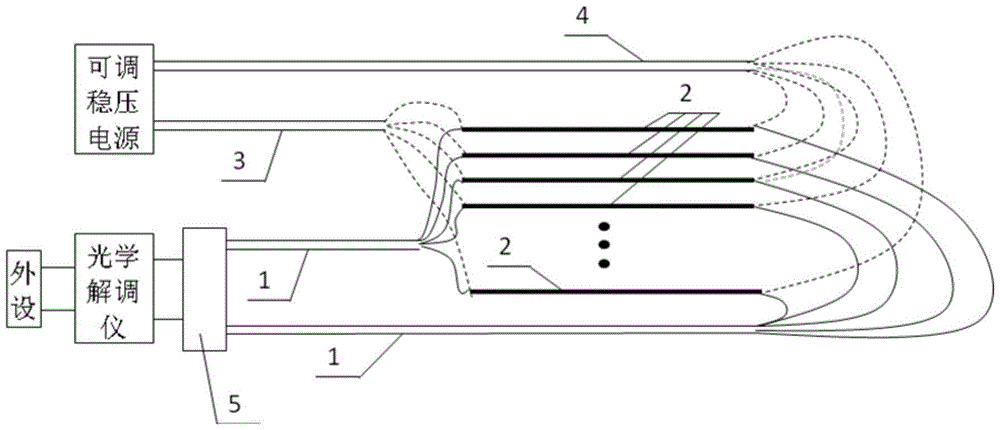

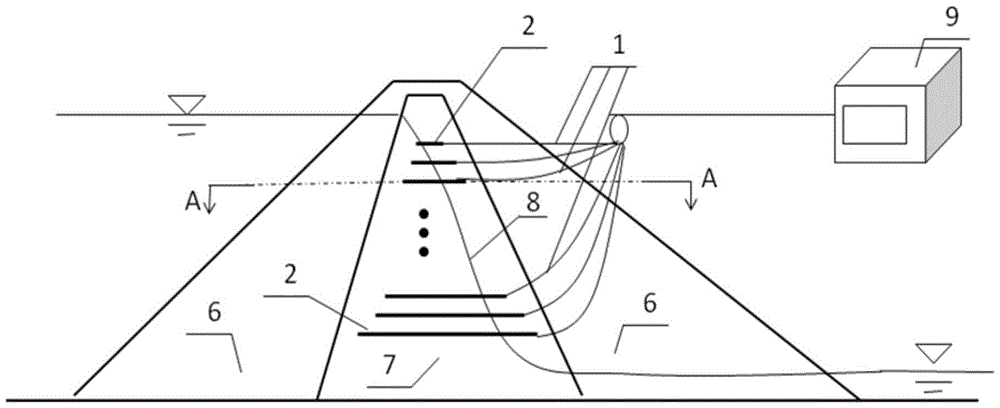

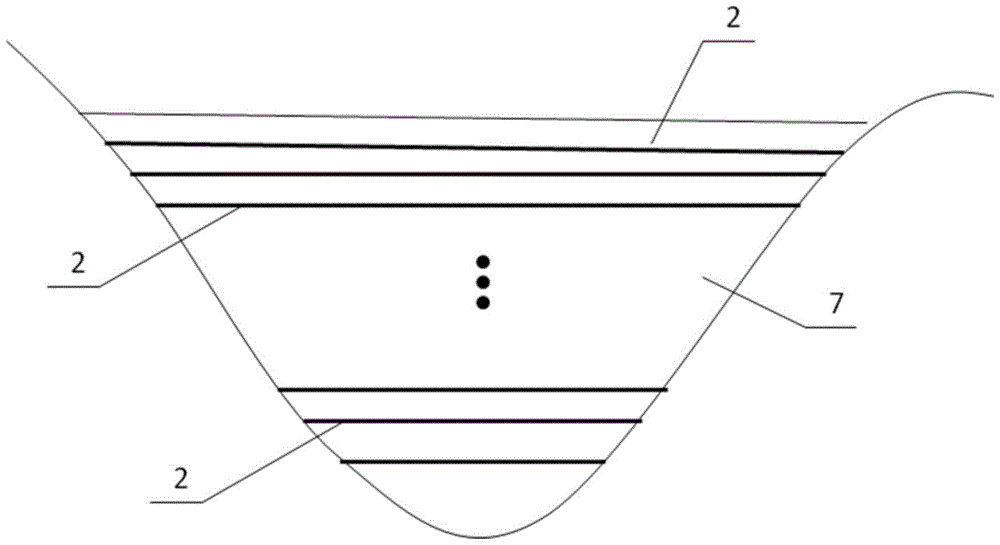

Method used

Image

Examples

Embodiment Construction

[0054] (1) The photoelectric composite cable is buried by the trenching method, and is manually backfilled and compacted with a viscous core wall material.

[0055] (2) The optical cable materials that have not been buried on site must be properly protected by special personnel.

[0056] (3) The observation operation of the optical fiber soaking line monitoring system is carried out by division, and it is automatically and controllably implemented with the help of the optical switch set up with the optical demodulator. For the selected observation area, the power supply is heated for about 10-30 minutes, and the temperature rise of the optical fiber tends to be stable, and the data can be collected by the host, and each area takes about 1-5 minutes (by the way, it is easy to see that the power consumption and energy consumption of the whole system are limited).

[0057] (4) The optical cable for monitoring the groundwater level of important parts along the anti-seepage curtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com