Socket and spigot joint type steel pipe concrete beam storage pedestal and construction method thereof

A technology for concrete-filled steel tubes and concrete-filled steel tubular columns is applied in the field of socket-type concrete-filled steel tube beam storage pedestals and their construction fields, which can solve the problems of high cost, long construction period, and increased engineering costs, and achieves solving the problems of long construction period, saving construction period, and saving The effect of rebar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

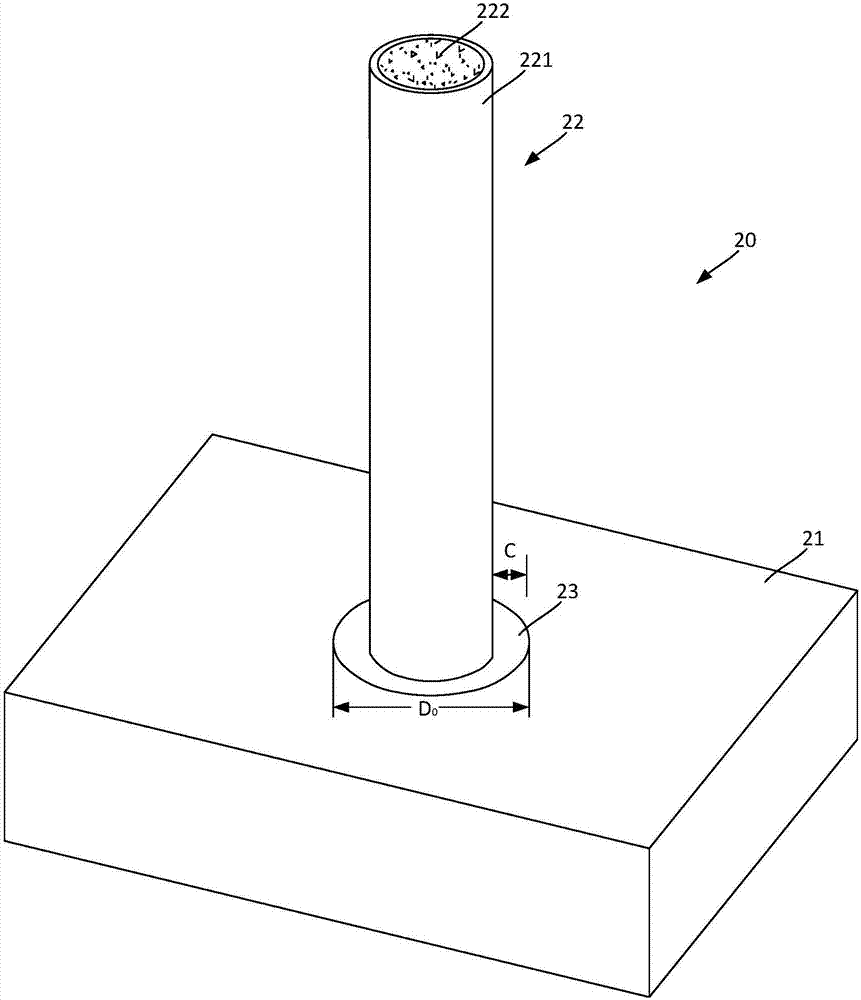

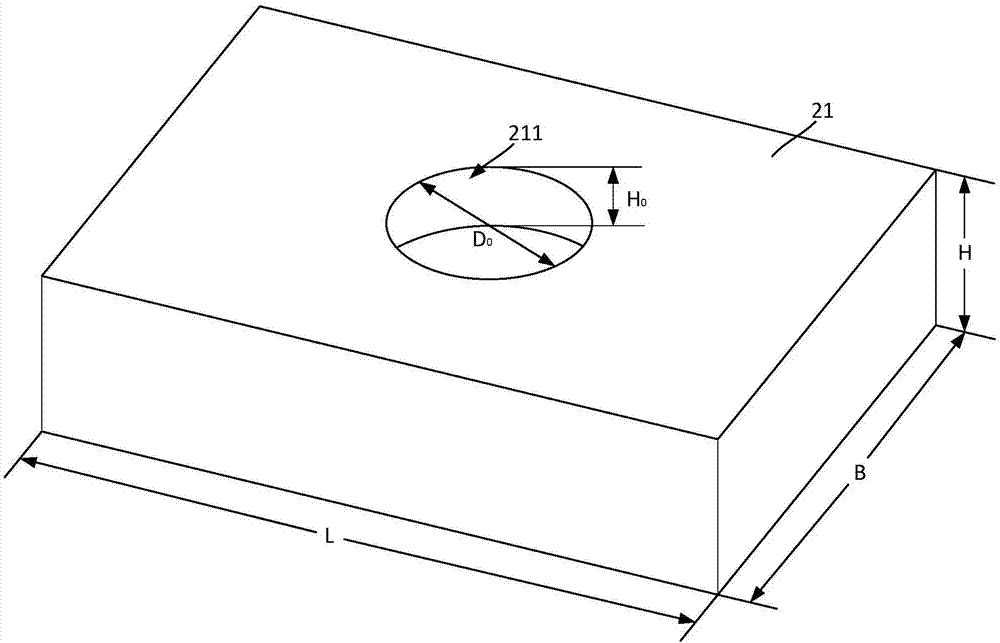

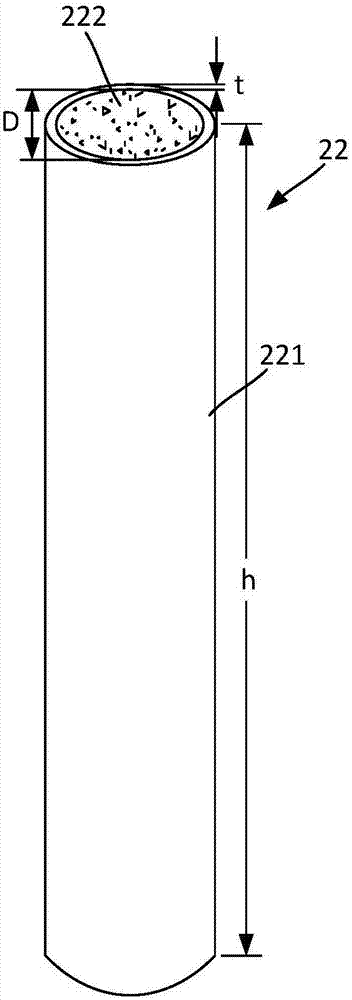

[0062] refer to figure 1 , The present invention provides a socket-type steel pipe concrete beam storage pedestal and its construction method, which are used to solve the problems of long construction period and high cost of the traditional integral reinforced concrete beam storage pedestal. The present invention adopts a socket type beam storage pedestal, in which the foundation platform and the concrete-filled steel tube column can be prefabricated separately, and then wet-joined together through embedded concrete, realizing the embedded connection of the foundation platform and the steel tube concrete column The integrated structure, and the foundation platform and the concrete-filled steel tube column are all poured with concrete, without reinforcement configuration, which saves reinforcement and saves the time for binding the reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com