Construction Technology of Pipe Gallery in Loess Layer

A construction technology and technology of loess layer, applied in the field of construction technology of loess layer pipe gallery, can solve the problems of manpower consumption, material, tight construction period, rough wall of pipe gallery, etc., reduce man-hours, increase construction speed, and reduce earthwork excavation The effect of excavation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

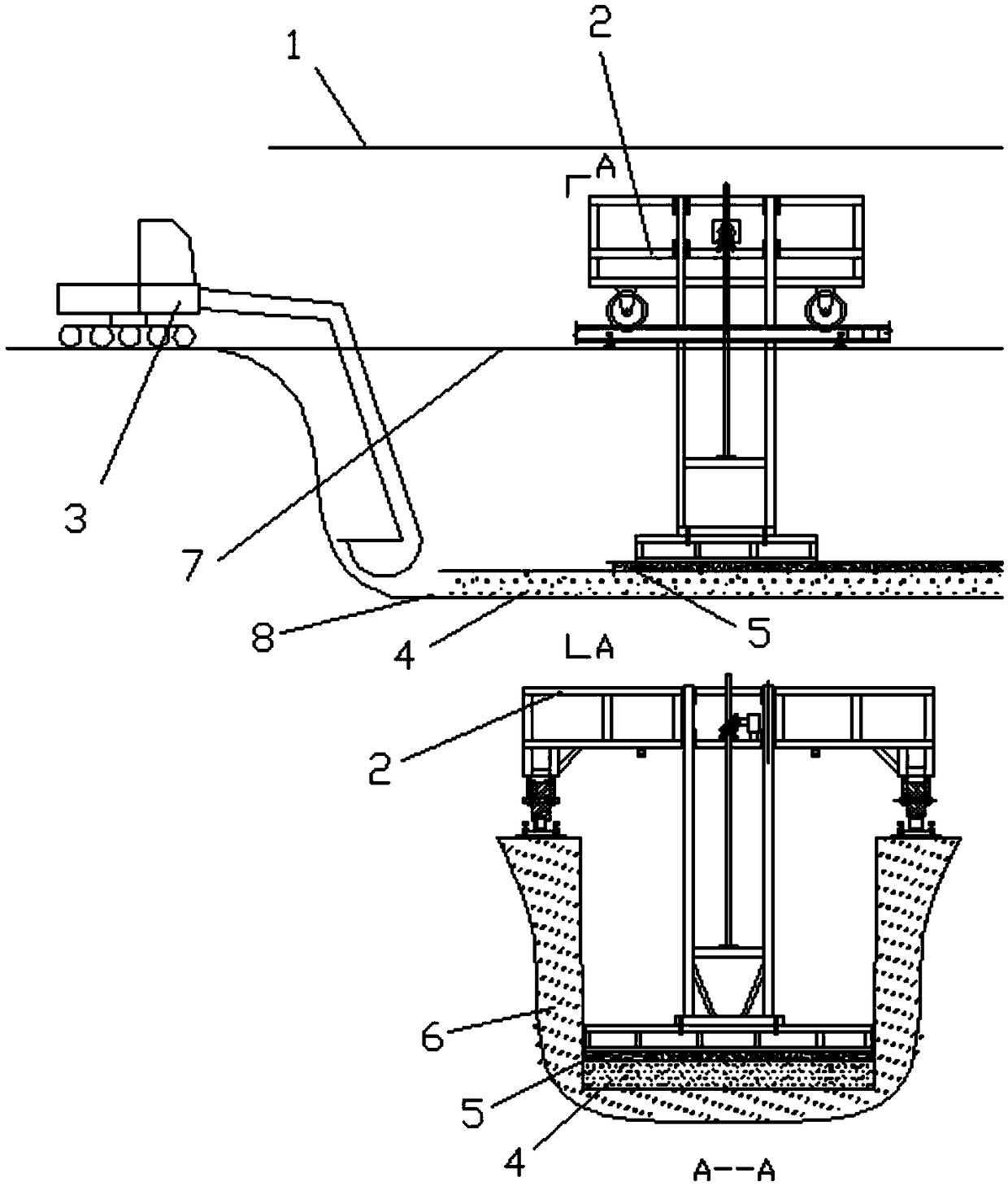

[0040]The present invention will be further described below in conjunction with the accompanying drawings.

[0041] A kind of loess layer pipe gallery construction technology of the present invention, it carries out construction according to the following steps:

[0042] Excavate in the loess covering layer to form a foundation trench with a slope of 90°, and sequentially manufacture and form several fastened modular boxes along the length direction of the foundation trench to form a loess layer pipe gallery;

[0043] Among them, the construction of the module box includes the following steps:

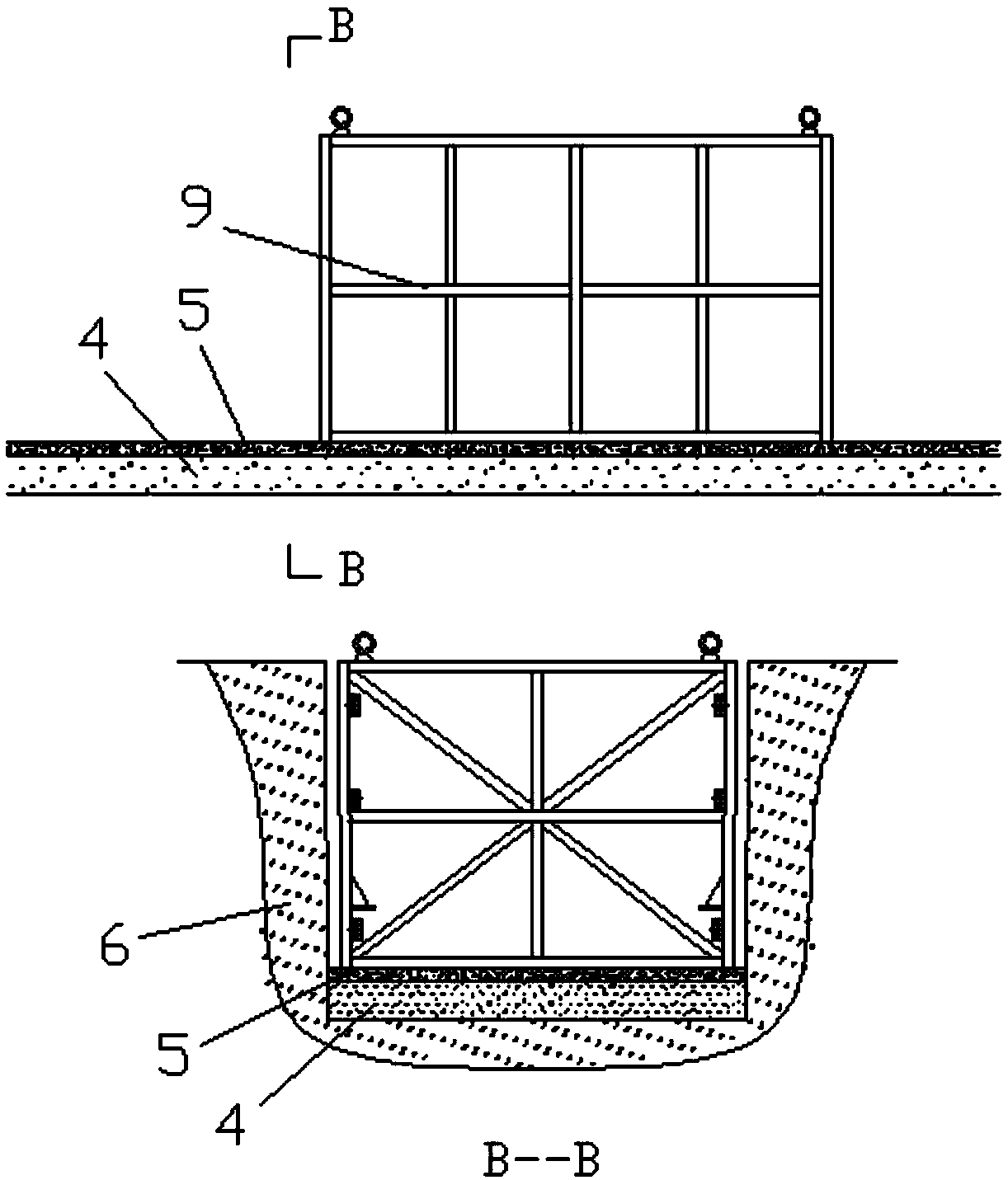

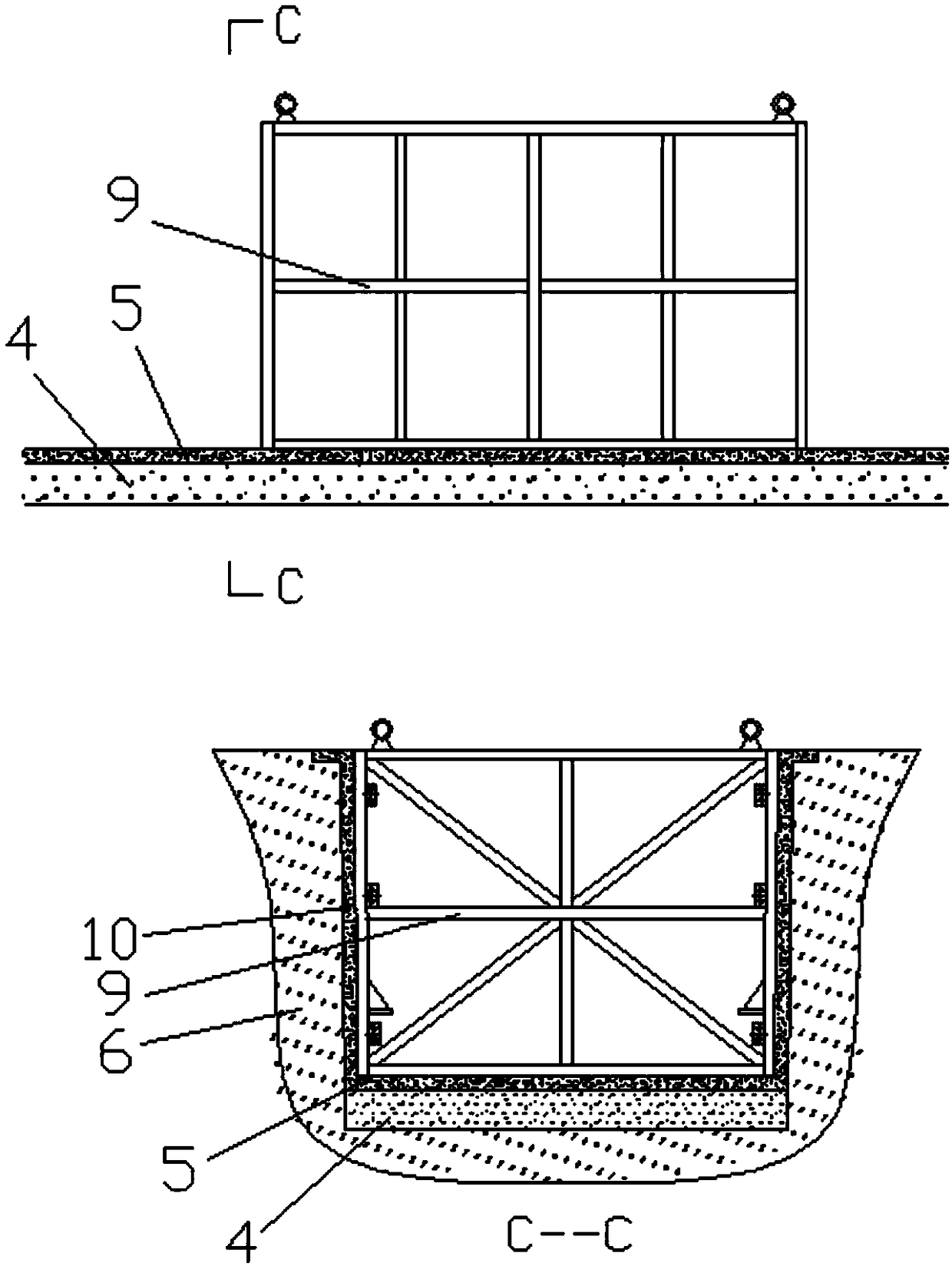

[0044] Step 1, laying the cement-soil stabilization layer 4 and the concrete cushion bottom plate 5 successively on the bottom surface of the foundation trench;

[0045] Step 2, install and form the vertical wall outer wall top form 9 on the described concrete cushion bottom plate 5 in the foundation groove, and pour concrete between the outer side of the vertical wall outer wall top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com