One-step forming mold used for pouring trench and using method of one-step forming mold

A technology for forming molds and grooves, which is applied to buildings, drainage structures, side ditches/curbs, etc. It can solve problems that affect the normal use of molds, personnel injury removal equipment, and large groove bending deformation, so as to improve the overall construction. Efficiency, reduced construction costs, reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

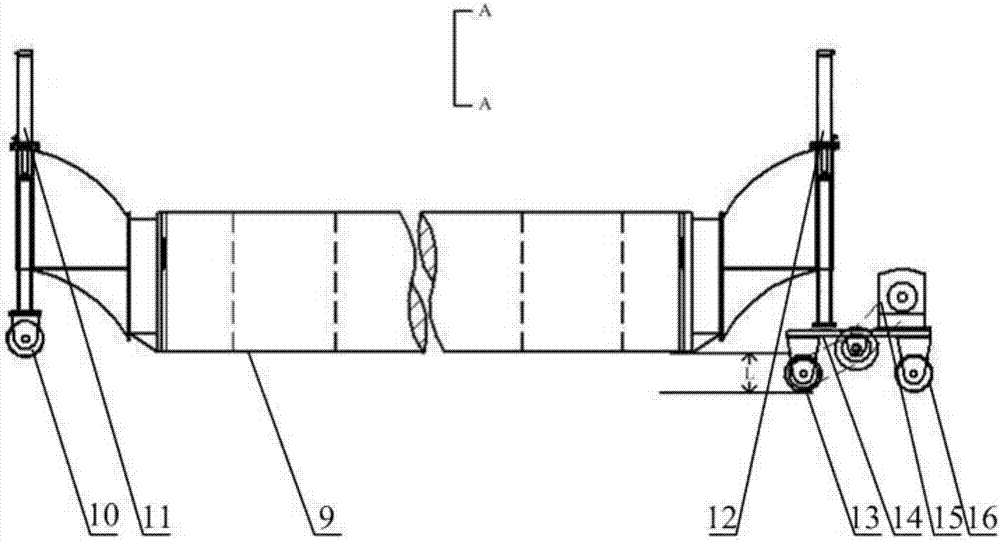

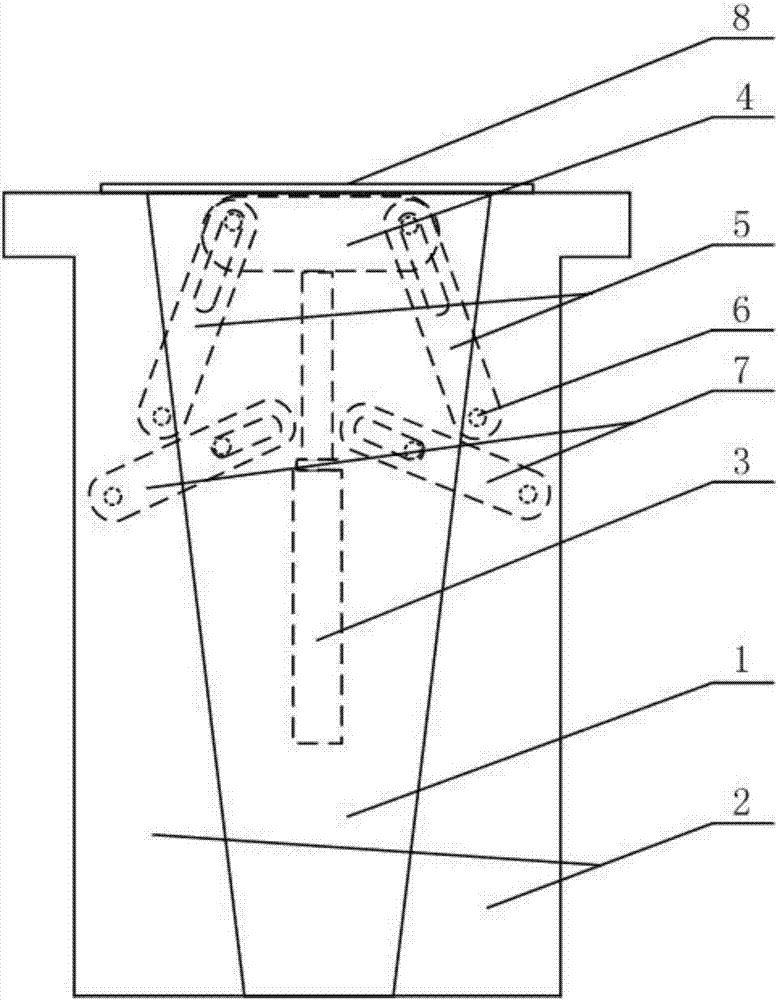

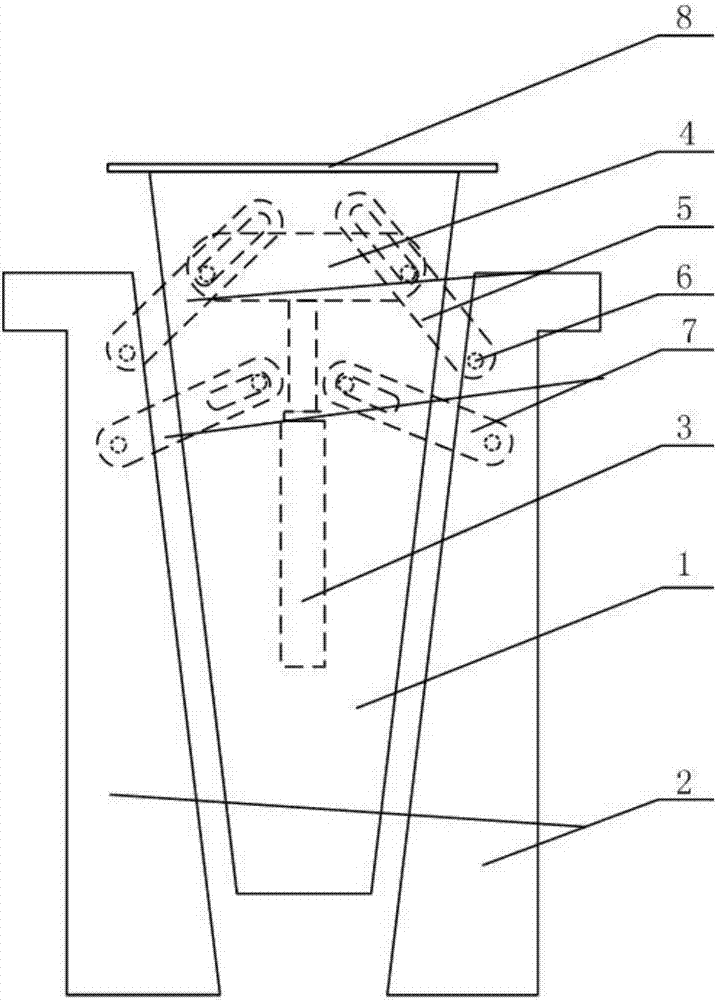

[0037] Such as figure 1 Shown, a kind of one-time forming mold that is used for pouring groove, comprises mold body; Mold body comprises middle box girder, side box girder, formwork pull bar, demoulding pull bar, the surface of middle box girder and the surface of side box girder are both The surface is smooth; the two side box girders are respectively located on both sides of the middle box girder; the middle box girder is equipped with a molding hydraulic cylinder with one end connected to the inside of the middle box girder and the other end connected with a tie rod cross arm. In this embodiment, the upper port of the middle box girder is provided with a limit plate. When the mold body is in the mold setting state, the lower end of the limit plate is in contact with the upper surface of the corresponding side box girder, thereby ensuring that the middle box girder is in the mold setting state. The connection position of the box girder and the side box girder is determined, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com