Complex geological condition fully-mechanized working face split-close type fault crossing method

A technology of complex geological conditions and fully mechanized mining face, applied in surface mining, underground mining, mining equipment, etc., can solve problems affecting economic benefits, waste of resources, affecting production efficiency, etc., to improve economic benefits, reduce construction costs, The effect of good usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

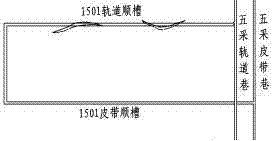

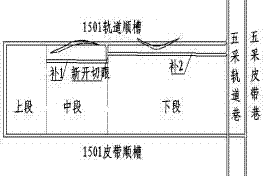

Image

Examples

Embodiment 1

[0041] Example 1: In the step 2), when the upper section of the working face is recovered to the fault, the 15 supports and the 15 sections of the scraper conveyor middle trough equipment in the shrinking part are removed, and 7 of the supports and 7 sections are scraped The middle trough of the slab conveyor is directly transported into the newly opened cut hole for installation, and the remaining 8 brackets and the middle trough of the 8-section scraper conveyor are directly raised. After the working face has been reduced, continue to advance the middle section. When it is advanced to the position of making up the cut eye, the working face will be combined. After the equipment is docked, continue to advance the lower working face.

Embodiment 2

[0042] Embodiment 2: The step 3) before the equipment is installed, determine the mounting position of the bracket in the new cut eye, and mark the installation positions of the remaining brackets at a distance of 1.5m. Then, the stent retracted from the retracted surface is directly transferred to the new cut eye and installed according to the corresponding position. The middle trough of the scraper conveyor will not be laid for the time being, and it should be placed on the side against the coal wall so that there is enough space for the tail of the pulling and moving machine when the working surface is closed.

Embodiment 3

[0043] Example 3: The step 4) In the working face joint, it includes two steps of joint preparation work and joint work. The joint preparation work includes strengthening the stubble joint support when the middle section of the working face is advanced to 20-25m from the joint front The relative position control. If the gap between the two brackets at the stubble joint is small or too large, it will cause difficulty in the stubble joint. In order to avoid the occurrence of the above, measures must be taken to control it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com