Special-shaped micro stepped bearing

A stepped bearing, miniature technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of not forming oil pressure, not forming lubricating oil film, not having load capacity, etc., to achieve good lubricating oil film and good friction reduction Wear-resistant effect, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

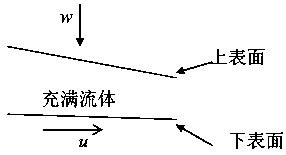

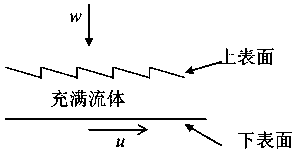

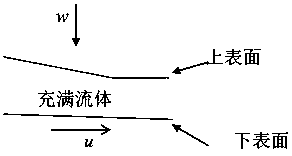

[0029] A special-shaped miniature stepped bearing, comprising a paired stationary plate 1 and a moving plate 2, the stationary plate 1 has a stepped surface, the stationary plate 1 includes protruding surfaces and concave surfaces arranged in sequence, the moving plate 2 adopts a flat surface, and the paired The working surfaces of the stationary flat plate 1 and the moving flat plate 2 are parallel to each other, an oleophilic coating 3 is coated on the convex surface of the stationary flat plate 1, and an oleophobic coating 4 is coated on the concave surface of the stationary flat plate 1 , the moving direction of the moving plate 2 is from the protruding surface of the stationary plate 1 to the concave surface of the stationary plate 1, and the gap between the protruding surface of the stationary plate 1 and the surface of the moving plate 2 is smaller than the concave surface of the stationary plate 1 and the moving plate 2 surface gap, the gap between the two paired statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com