Novel garbage treatment furnace for effectively improving garbage treatment effect

A new type of waste treatment technology, applied in incinerators, combustion types, combustion methods, etc., can solve the problems of difficult control of waste conditions, difficulty in achieving heat treatment effects, etc., and achieve the effects of good waste treatment effect, improved effect, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

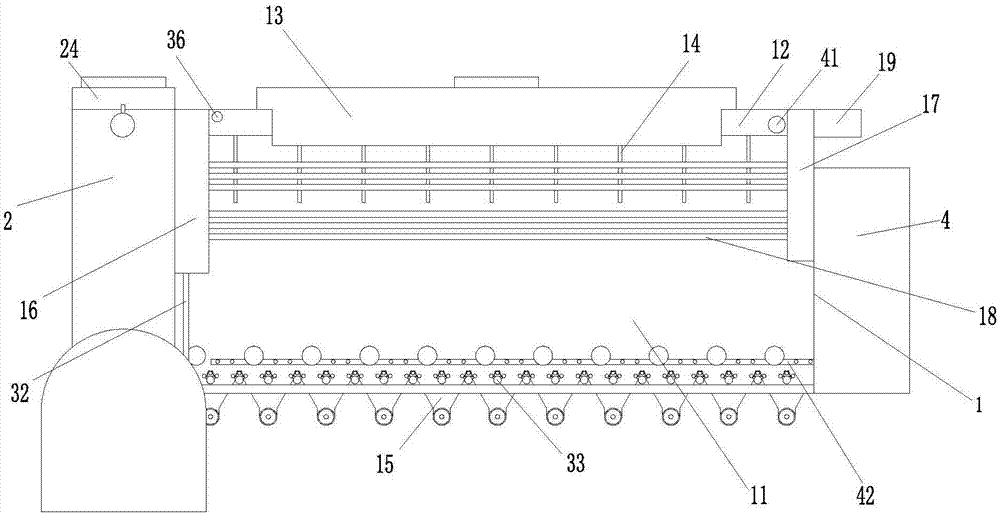

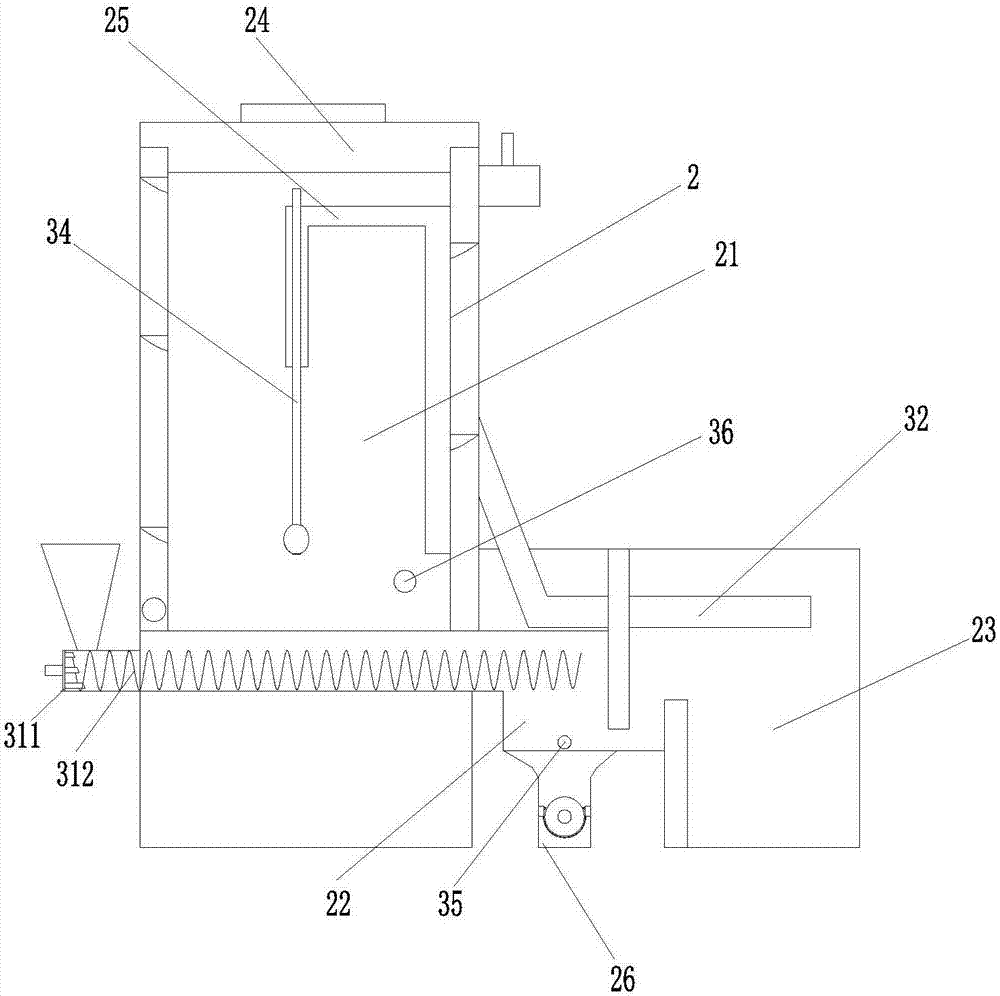

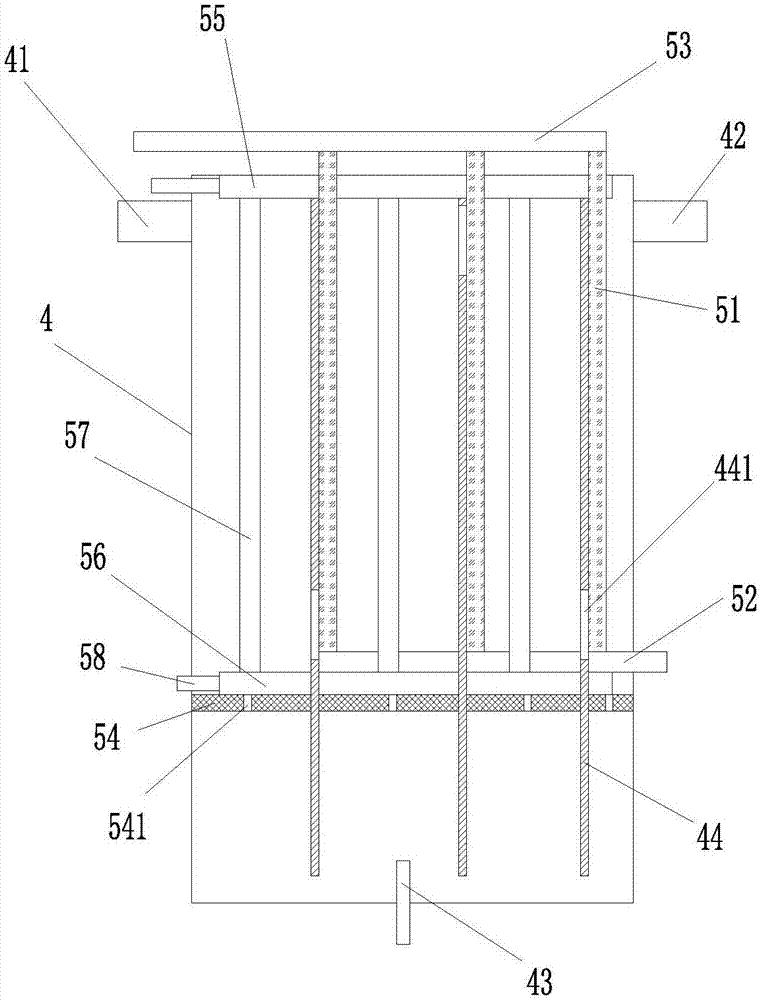

[0021] refer to figure 1 , figure 2 with image 3 As shown, a novel garbage disposal furnace that effectively improves the garbage disposal effect proposed by the present invention includes a main furnace body 1, an auxiliary furnace body 2, a first auxiliary mechanism, an auxiliary box 4 and a second auxiliary mechanism;

[0022] The main furnace body 1 is provided with a main furnace chamber 11 and an internal circulation gas storage chamber 12. The main furnace body 1 is located on the upper part of the main furnace chamber 11 and is equipped with a main furnace feeding door 13. The main furnace body 1 is equipped with a 11 The upper part and the air-inducing pipe 14 of the internal circulation gas storage chamber 12, the main furnace body 1 is located at the bottom of the main furnace chamber 11 and is equipped with a first slagging device 15;

[0023] The auxiliary furnace body 2 is provided with an auxiliary furnace chamber 21, an auxiliary furnace chamber 22 and a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com