Detection device and method for detecting isolation degree and input optical loss indexes of filter plate

A detection device and filter technology, applied in the field of optical communication, can solve problems such as difficulty in batch testing, inability to guarantee the overall quality of filters, low efficiency, etc., achieving easy batch testing, realizing batch testing, and reducing testing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be clearly and completely described below.

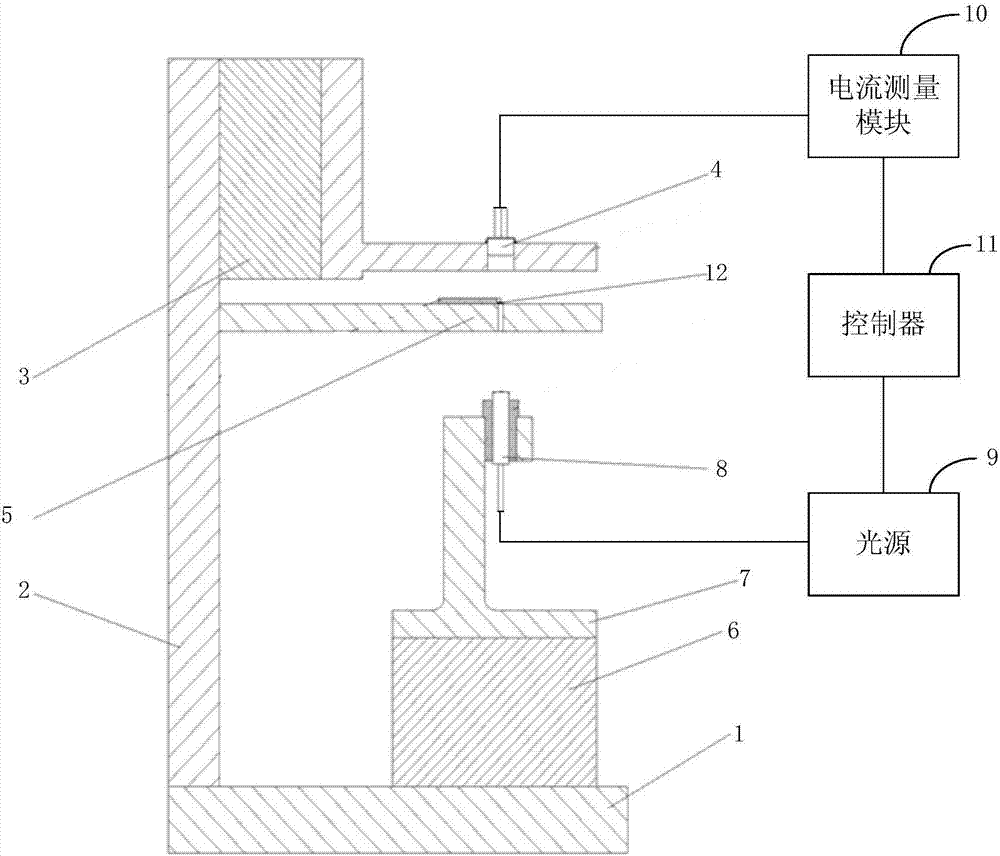

[0033] figure 1 A schematic diagram of the structure and principle of the detection device for the isolation degree of the filter 12 and the input light loss index provided by an embodiment of the present invention. Such as figure 1 As shown, the detection device includes a base 1, a riser 2 installed on the base 1 and perpendicular to the base 1, a Z-axis displacement platform 3 installed on the riser 2, and a photodetector installed on the Z-axis displacement platform 3 4. The filter placement platform 5 installed on the vertical plate 2 and below the Z-axis displacement platform 3, the XY-axis displacement platform 6 installed on the base 1, and the XY-axis displacement platform 6 for fixing the collimator 8 The support column 7, the light source 9 connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com