Non-intervention type paster filling pipeline block monitoring device and method

A monitoring device and paste filling technology, applied in measuring devices, geophysical measurements, instruments, etc., can solve the problems of destroying the structural integrity of the pipeline system, high sensitivity requirements, complex structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

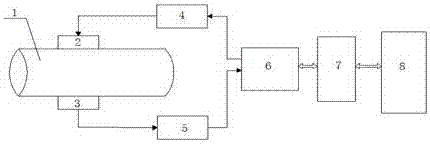

[0027] Such as figure 1 As shown, a non-interventional paste filling pipeline blockage monitoring device includes an ultrasonic monitoring device, a PLC controller 7, and a computer 8;

[0028] The ultrasonic monitoring device comprises an ultrasonic transmitting probe 2, an ultrasonic receiving probe 3, an ultrasonic transmitting device 4, an ultrasonic receiving device 5, and a single-chip microcomputer 6. The ultrasonic transmitting probe 2 and the ultrasonic receiving probe 3 are respectively arranged on both sides of the filling pipeline 1 to be monitored. The transmitting probe 2 is connected to the ultrasonic transmitting device 4, the ultrasonic transmitting device 4 is connected to the single-chip microcomputer 6, the ultrasonic receiving probe 3 is connected to the ultrasonic receiving device 5, and the ultrasonic receiving device 5 is connected to the single-chip microcomputer 6; the single-chip microcomputer 6 controls the ultrasonic transmitting device 4 to transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com