Connecting hardware for power transmission and distribution

A technology for connecting fittings, power transmission and distribution, applied in conductive connection, electrical component connection, needle tip/slotted plate contact used for penetrating insulated wire/cable core wire, etc., can solve problems such as poor firmness and easy loosening , to achieve the effect of preventing retrogression, ensuring stable reliability, and excellent anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

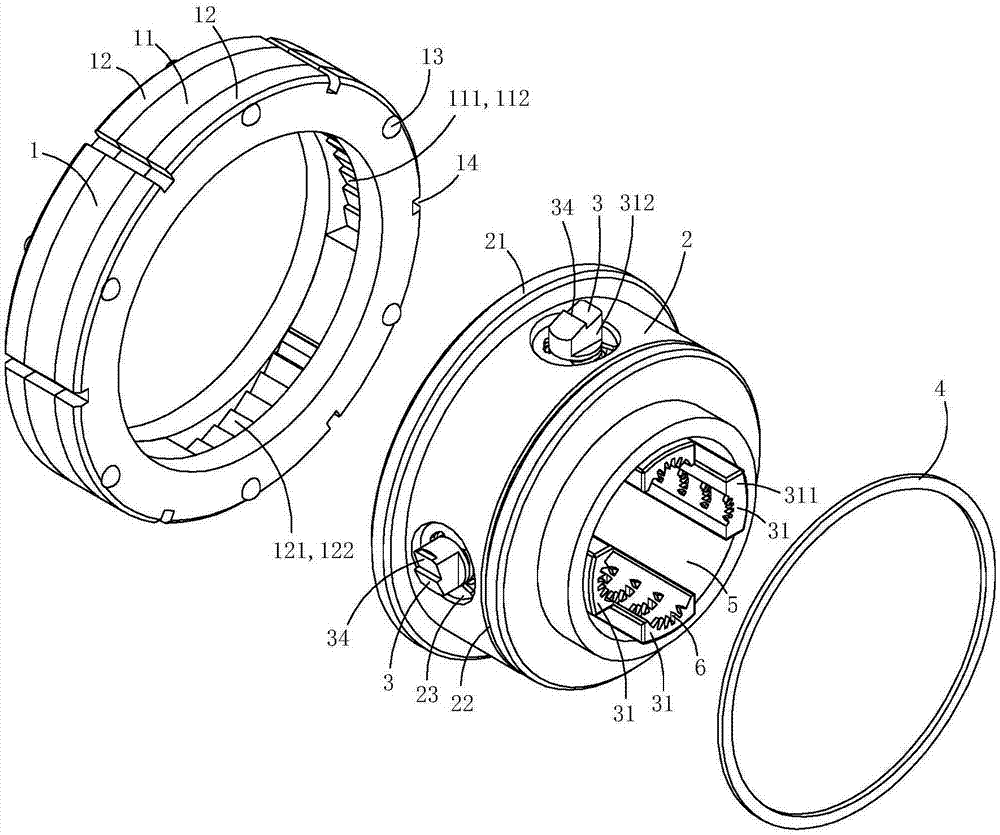

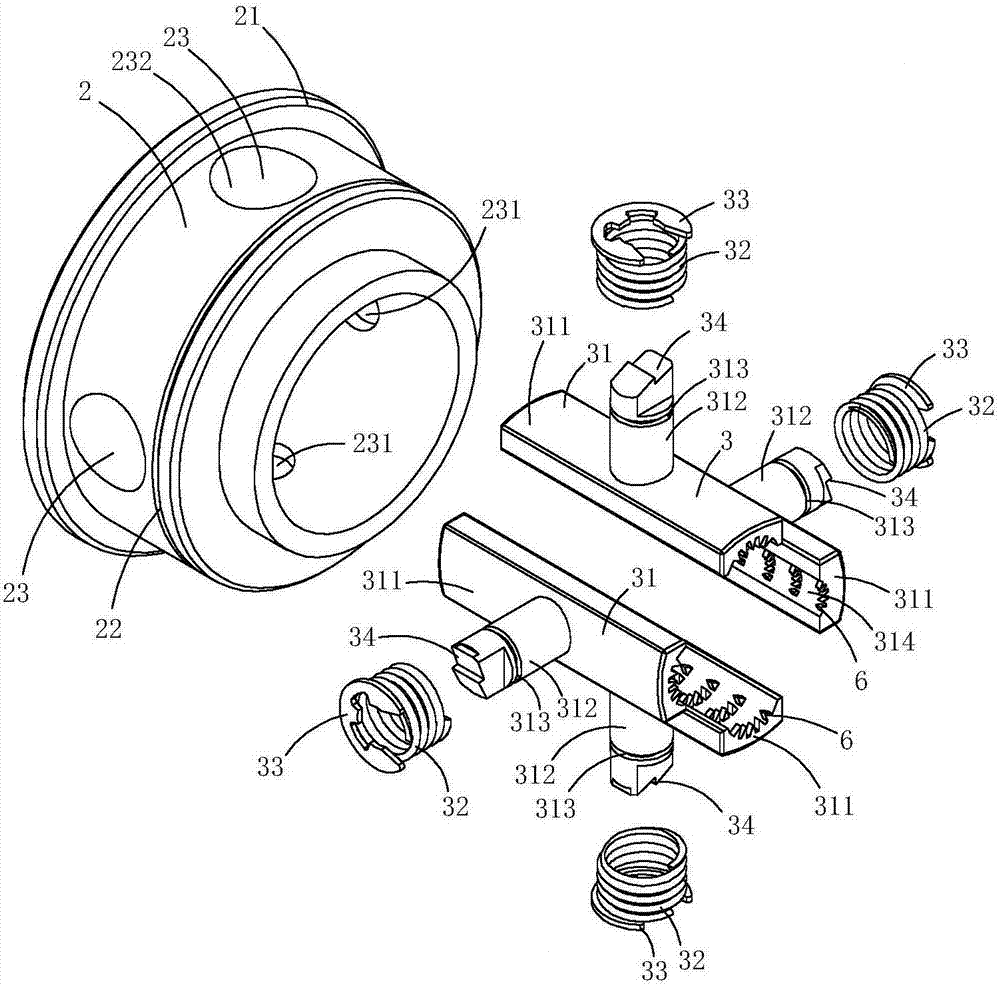

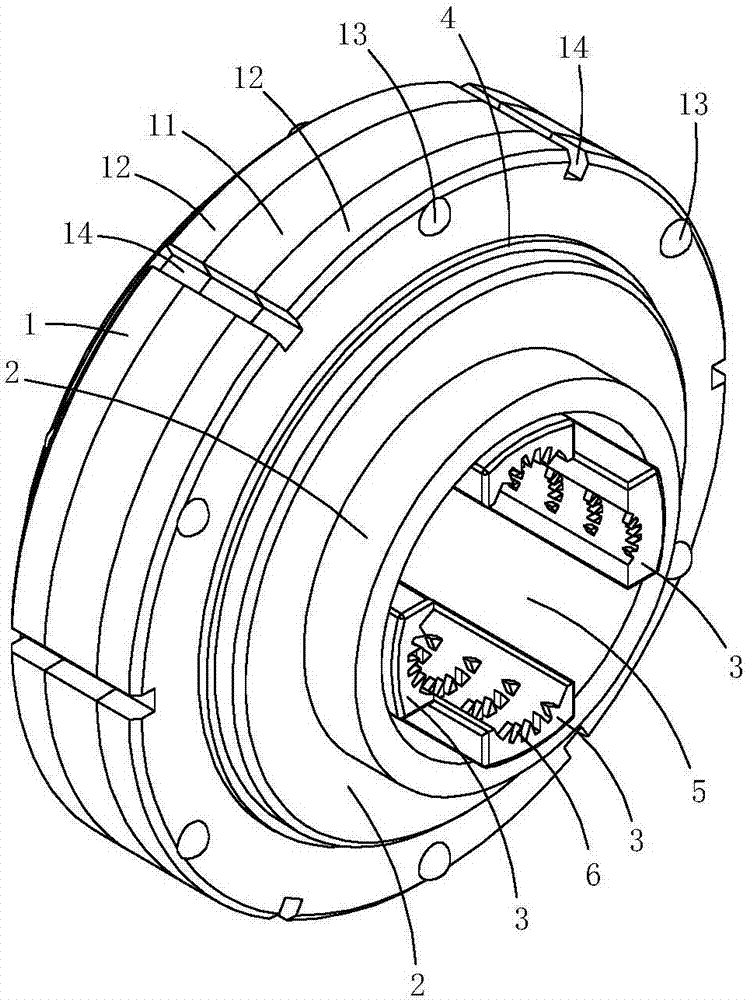

[0021] This embodiment is a kind of electric power fittings, see Figure 1 to Figure 5 As shown, it includes a pressure ring 1 , a core tube 2 , four pressure jaw assemblies 3 and an axial retaining ring 4 .

[0022] The pressure ring 1 includes a ratchet ring 11, two clamping rings 12 on both sides of the ratchet ring and a plurality of coupling rivets 13, the two clamping rings clamp the ratchet ring, and the coupling rivets penetrate through the ratchet ring and the ratchet ring along the core tube axial direction. Two clamping rings, so that the ratchet ring and the two clamping rings are fixedly connected as a whole. The inner peripheral wall of the ratchet ring is provided with a plurality of slope grooves 111, and each slope groove is provided with a plurality of wedge-shaped anti-off teeth 112; in this embodiment, the inner peripheral wall of the ratchet ring and the inner peripheral wall of the clamping ring are coplanar, The outer peripheral wall of the clamping rin...

Embodiment 2)

[0032] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 6 to Figure 10 As shown, this embodiment also includes a mandrel 7 located in the lumen of the core tube; a plurality of arc-shaped clamping grooves 71 are provided on the outer peripheral wall of the mandrel, and each arc-shaped clamping groove extends axially along the core tube, and each arc-shaped clamping groove The clamping grooves are arranged opposite to the arc-shaped grooves on the inner wall of the corresponding one of the pressure jaws; each arc-shaped clamping groove and a corresponding arc-shaped groove are clamped to form a clamping hole 5; so this embodiment can form four clamping holes, which can be used for Clamp four cables at the same time.

[0033] The outer peripheral wall of the mandrel is provided with four supporting positioning convex plates 72 protruding along the radial direction of the core tube, and the inner peripheral wall of the core tube is provided wi...

Embodiment 3)

[0035] This embodiment is basically the same as Embodiment 2, the difference is: see Figure 11 As shown, this embodiment also includes a voltage transformer 8; the voltage transformer includes an annular base 81 for inductively generating a secondary voltage and an annular ring body 82 sheathed on the annular base. A clamping ring is provided with an annular installation notch 121 at one end adjacent to the ratchet ring; the voltage transformer is embedded in the installation notch; an intelligent central control module is provided in the annular ring body for controlling the outer wall of the voltage transformer The temperature sensor for temperature detection and the wireless sensing unit for sending information to the remote host; the secondary terminal of the voltage transformer, the temperature sensor and the wireless sensing unit are all connected to the intelligent central control module.

[0036]The sensing unit of the temperature sensor is arranged close to the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com