Laminate for blister pack, blister pack using same, blister pack package, and method for manufacturing same

A technology of blister packaging and lamination, which is applied to the fields of blister packaging, blister packaging, and blister packaging, and can solve the problems of mistaken drinking or eating, time-consuming, and drug deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

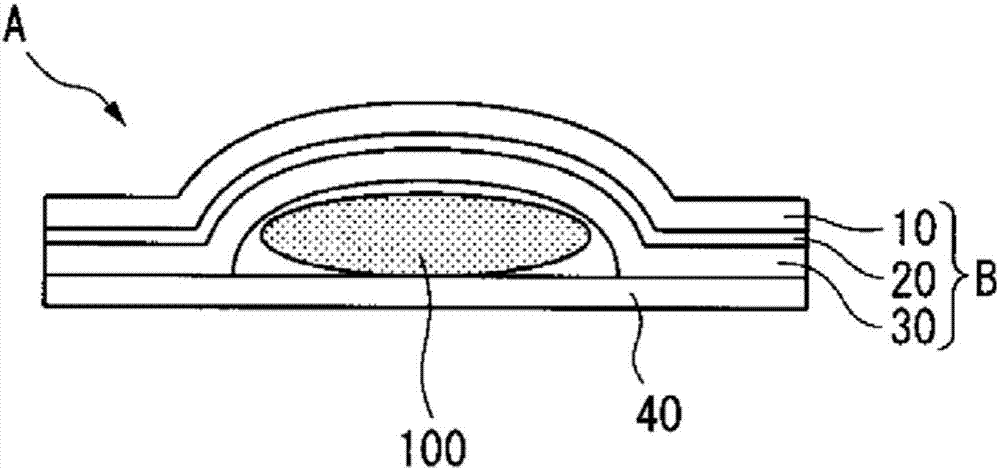

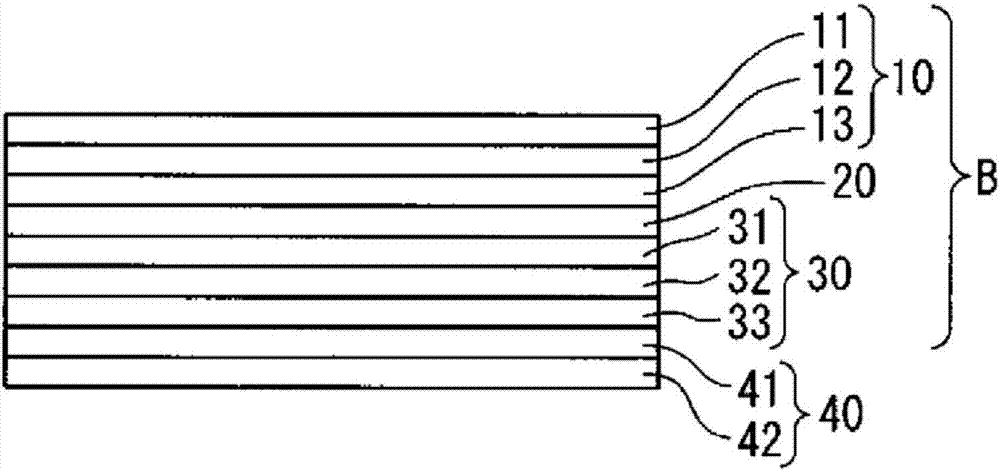

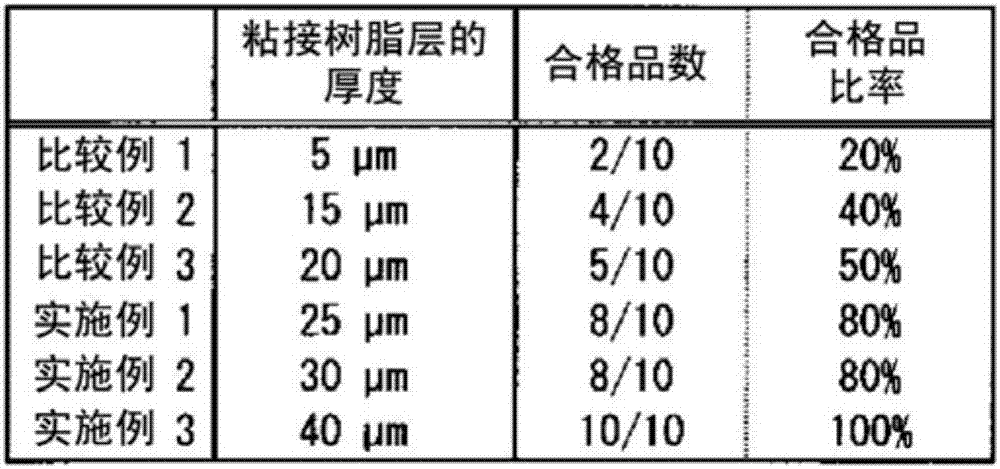

[0115] "Manufacturing of Laminates for Blister Packaging"

[0116] 〈Preparation of substrate film〉

[0117] Using a dry laminator (INVEX pilot coater, Technosmart Co., Ltd.), a 12 μm polyethylene terephthalate (Lumirror 12S10, Toray Co., Ltd.) as a reinforcing layer was laminated on a 25 μm polyethylene terephthalate as a base layer A base film was obtained on a laminate of a nylon (Ny) film and a 40 μm aluminum (Al) foil as an aluminum layer (AL / AL base, foil manufactured by UACJ Co., Ltd.). Here, as an adhesive for dry lamination, a polyurethane-based adhesive containing a main agent (TAKELAC (trademark) XA1151, Mitsui Chemicals, Inc.) and a curing agent (TAKENATE (trademark) A12, Mitsui Chemicals, Inc.) was used. , at a pulling speed of 10 m / min, an adhesive layer with a thickness of 5 μm was formed.

[0118] 〈Manufacture of absorbent film〉

[0119] Using a twin-screw extruder (PCM70, Ikegai Co., Ltd.), the zeolite (molecular sieve 4A, UNION SHOWAK.K.) of the inorganic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com