Method and device for producing fiber molded parts, and fiber molded parts

A technology of molded parts and fibers, which is used in the field of manufacturing fiber molded parts and devices, and fiber molded parts, can solve problems such as failure, and achieve long service life and simple design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

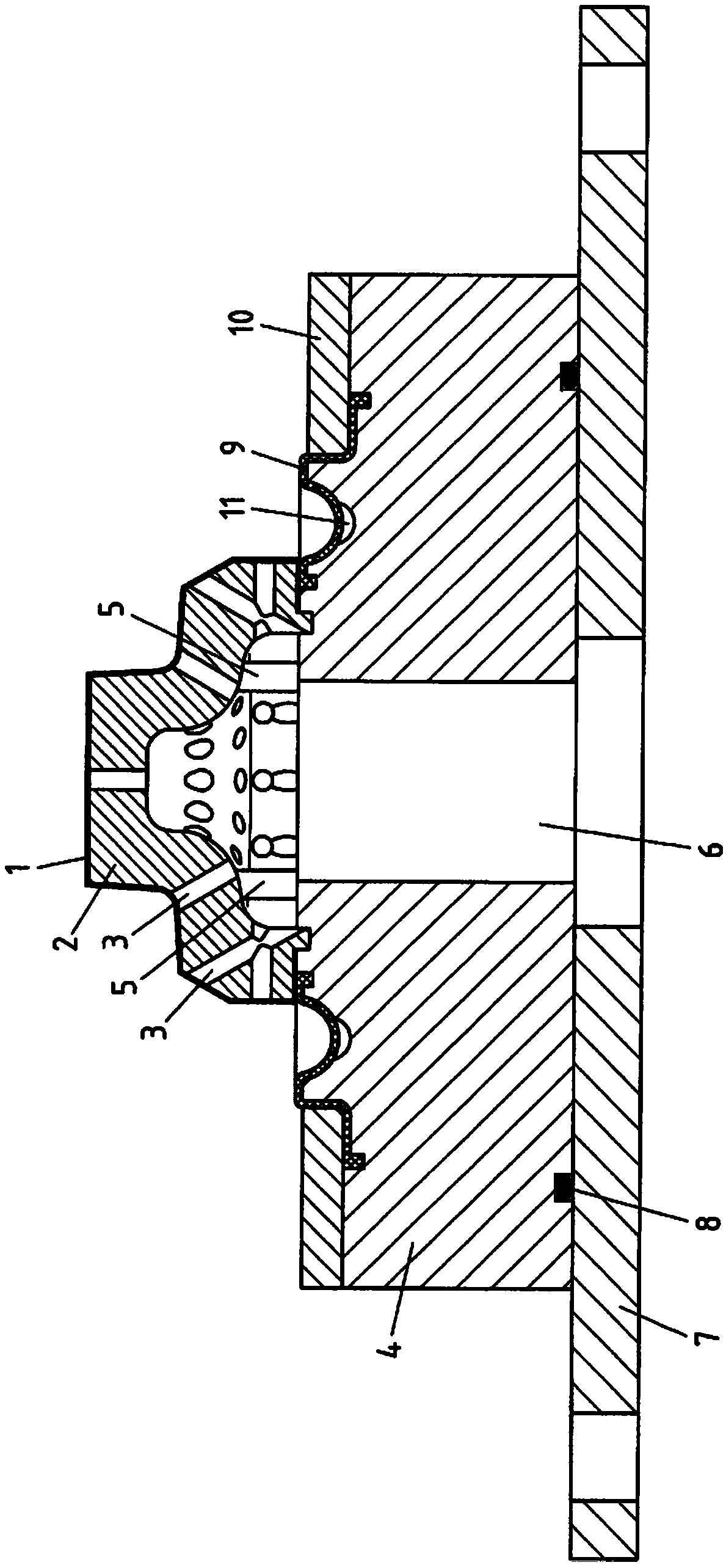

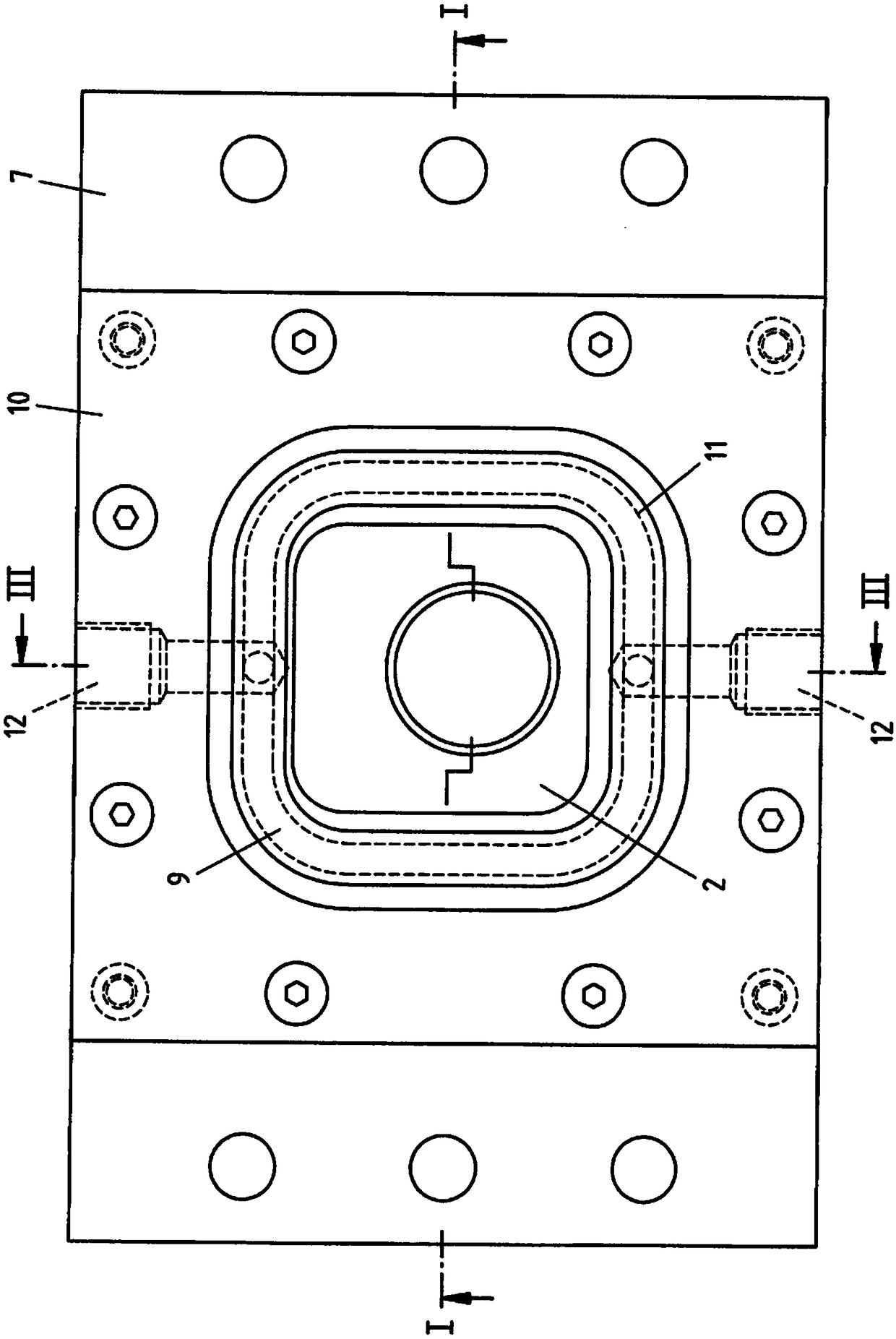

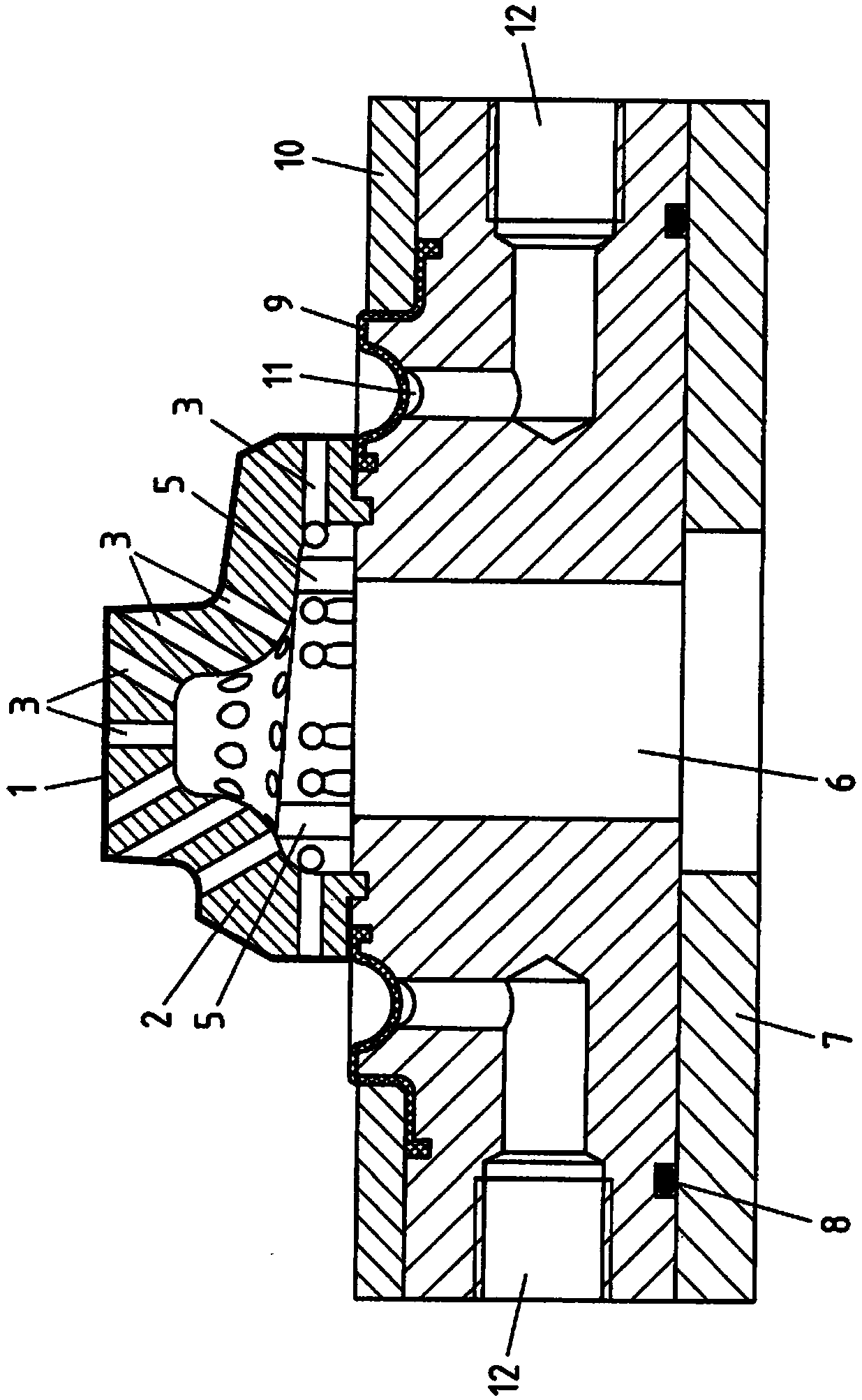

[0041] exist figure 1 In , firstly the molding mesh 1 is seen, which extends along the outer contour of the molding tool 2 . The molding tool 2 is hollow on the inside and has a plurality of channels 3 which, in the depicted and in this respect preferred embodiment, are designed as drilled holes from suitable points of the molding tool 2 The surface at extends up to the hollow interior of the molding tool 2. The molding tool 2 is located on the tool holder 4 and is connected to the tool holder 4 from below by bolts 5 which may only be partly visible. The tool holder 4 also has a central supply line 6 which can likewise be designed as a borehole.

[0042] Below the tool holder 4 a fixed plate 7 can be seen which in turn has a central supply line for the air supply of the molding tool 2 . The seal 8 , which is preferably designed as an O-ring, provides the necessary impermeability of the contact area between the tool holder 4 and the fixing plate 7 . An expandable sleeve 9 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com