Optimizing method of contact pressure between water cutting rubber and work roll in secondary cold rolling mill

A secondary cold rolling, contact pressure technology, applied in tension/pressure control, manufacturing tools, metal rolling, etc., can solve the problem of less research on the influence of oil film thickness, and achieve the improvement of lubricating performance and product surface quality, lubricating oil film Equal thickness, optimized contact pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

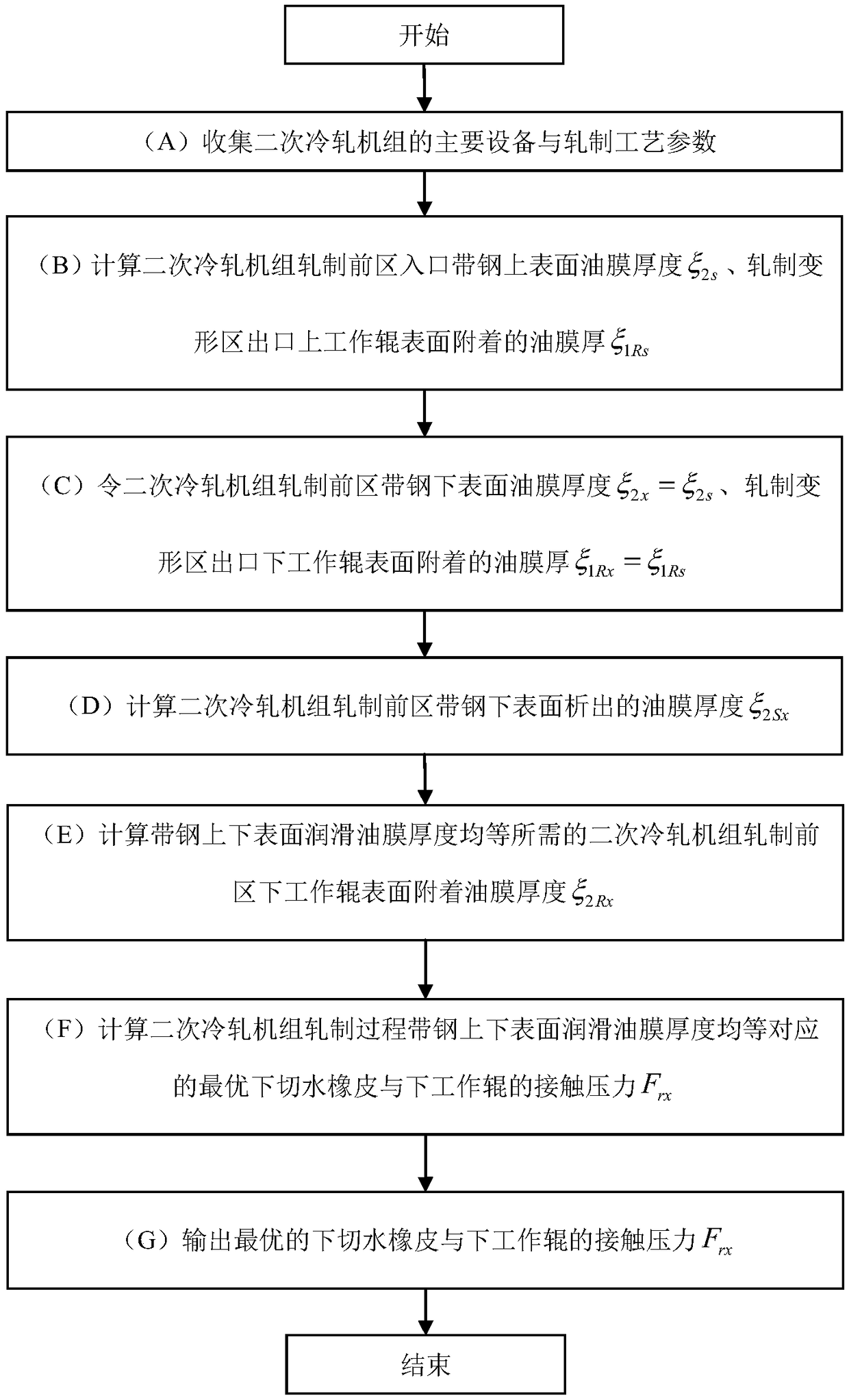

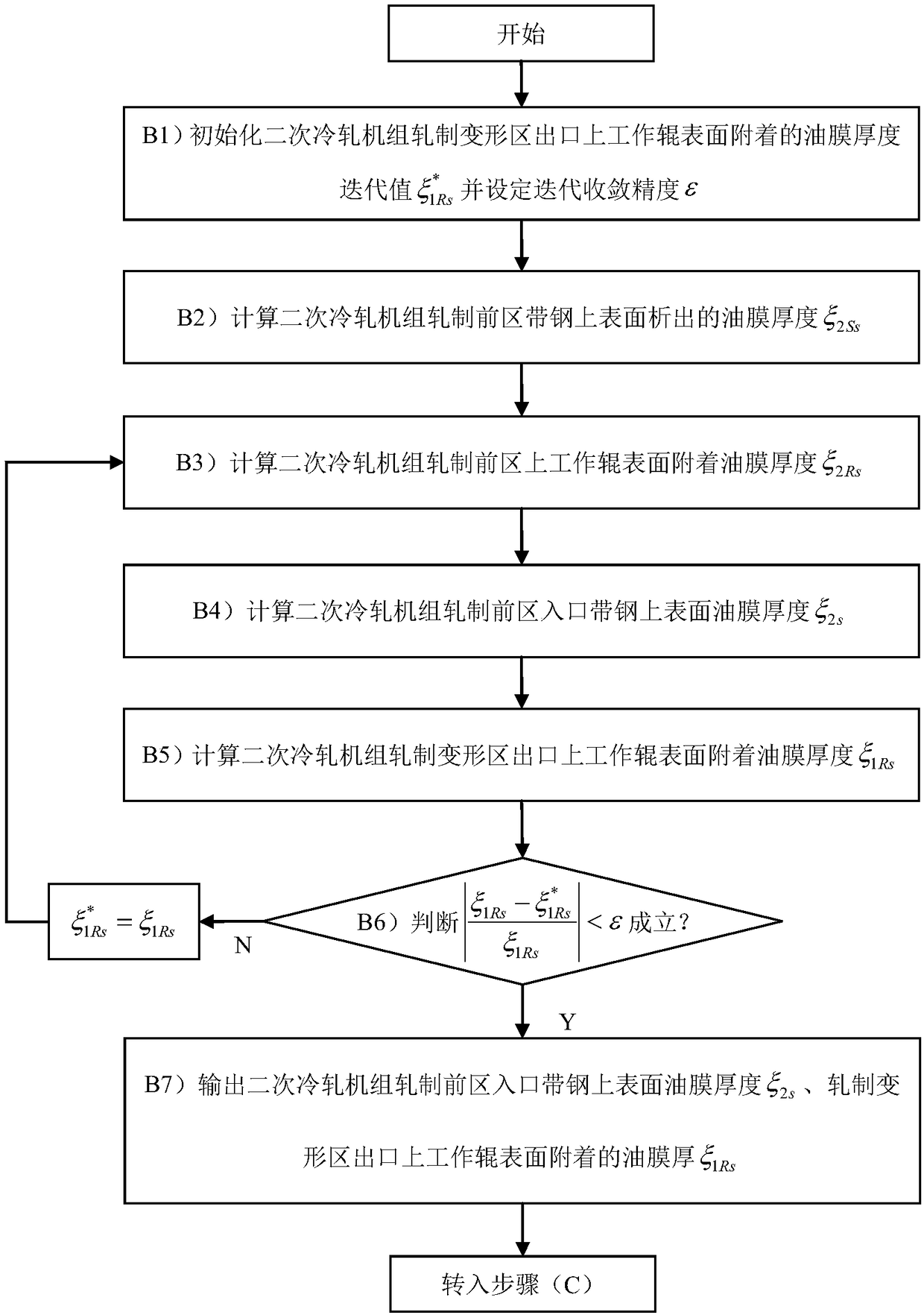

[0037] Taking a secondary cold rolling unit as an example, according to figure 1 The total calculation flow chart shown:

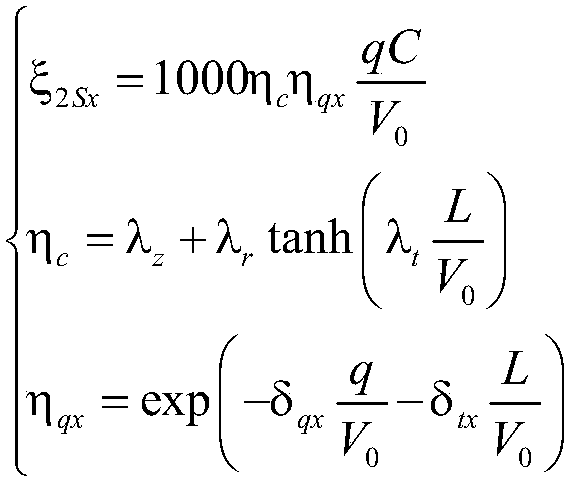

[0038] First, in step (A), the main equipment and rolling process parameters of the secondary cold rolling unit are collected, including: emulsion flow density q=10.5L / min / m, emulsion flow concentration C=5.8%, emulsion flow density Precipitation distance L=0.5m, rolling speed V at the entrance of the rolling mill 0 =706m / min, work roll speed V R =817m / min, rolling speed V at the exit of the rolling mill 1=882m / min, rolling bite angle α=0.013rad, entrance deformation resistance K 0 =320MPa, back tension σ 0 =95MPa, rolling oil initial dynamic viscosity η 0 =0.025Pa·s, rolling oil pressure viscosity coefficient θ=0.012MPa -1 , Impact coefficient of precipitation rate λ z =0.236, precipitation rate wettability influence coefficient λ r =0.675, precipitation rate time influence coefficient λ t =132.5, influence coefficient δ qs =10.62, the time infl...

Embodiment 2

[0063] Taking a certain secondary cold-rolling unit as an example, at first, in step (A), collect the main equipment and rolling process parameters of the secondary cold-rolling unit, including: emulsion flow density q=14.2L / min / m, emulsification Liquid flow concentration C = 6.6%, emulsion precipitation distance L = 0.5m, rolling mill entrance rolling speed V 0 =555m / min, work roll speed V R =778m / min, rolling speed V at the exit of the rolling mill 1 =836m / min, rolling bite angle α=0.015rad, entrance deformation resistance K 0 =285MPa, back tension σ 0 =101MPa, rolling oil initial dynamic viscosity η 0 =0.025Pa·s, rolling oil pressure viscosity coefficient θ=0.012MPa -1 , Impact coefficient of precipitation rate λ z =0.236, precipitation rate wettability influence coefficient λ r =0.675, precipitation rate time influence coefficient λ t =132.5, influence coefficient δ qs =10.62, the time influence coefficient δ of the remaining rate of the strip upper surface ts =33...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com