Cold rolling direct spraying method of emulsified liquid

An emulsion and direct injection technology, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as maintenance difficulties, equipment congestion, and limited adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Now according to specific embodiments of the present invention, the application process of this technical solution is further described:

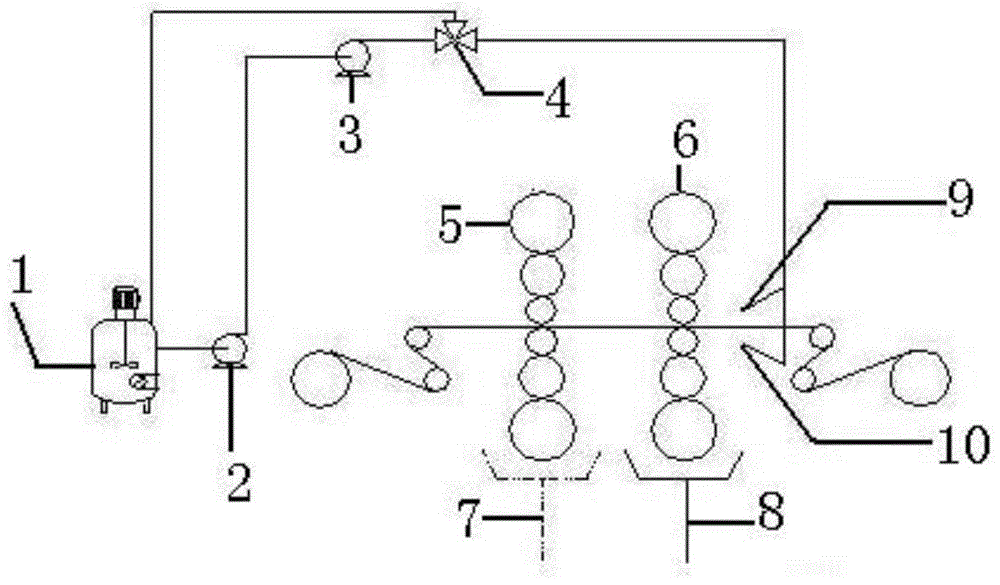

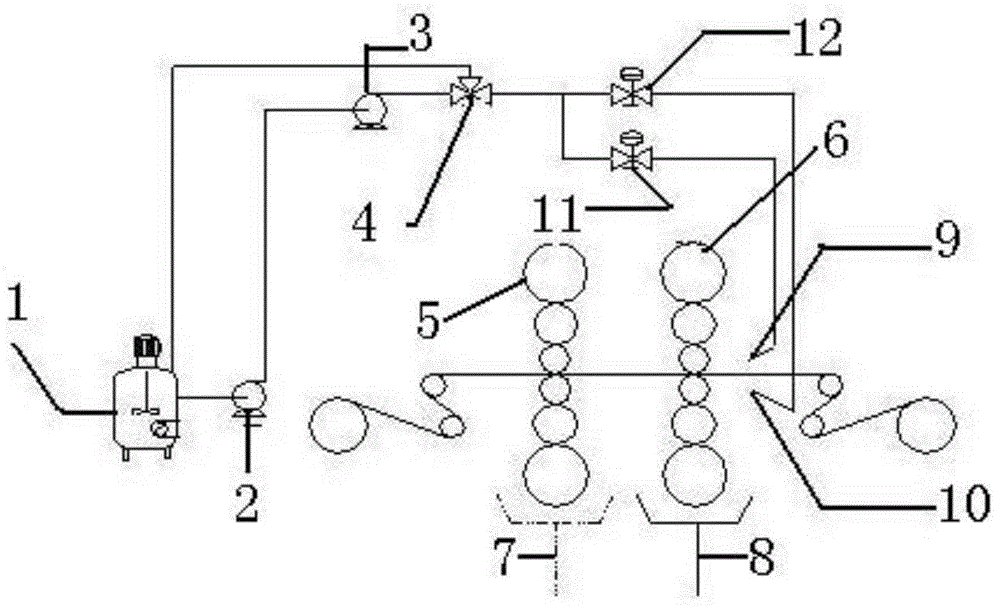

[0078] 1) The emulsion spray system in the present embodiment is as image 3 As shown, the system equipment and figure 1 The existing equipment and devices shown are basically consistent, and only the flow valves 11 and 12 are used to control the spraying of the upper nozzle 9 and the lower nozzle 10 respectively on the branch pipeline connecting the three-way valve 4 and the upper nozzle 9 and the lower nozzle 10 respectively. The emulsion flow rate on the upper and lower surfaces of the strip, so as to realize the separate control of the upper nozzle 9 and the lower nozzle 10, so that the upper nozzle 9 and the lower nozzle 10 have different spraying quantities;

[0079] 2) According to Figure 4 The steps shown determine the optimal distance s from the lower nozzle to the center of the mill 2 * :

[0080] (a) The distance s f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com