Variable capacity vane pump

A vane pump and capacity technology, applied in the direction of rotary piston pumps, pumps, pump control, etc., can solve problems such as energy loss, achieve the effect of reducing energy loss and suppressing large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach 〕

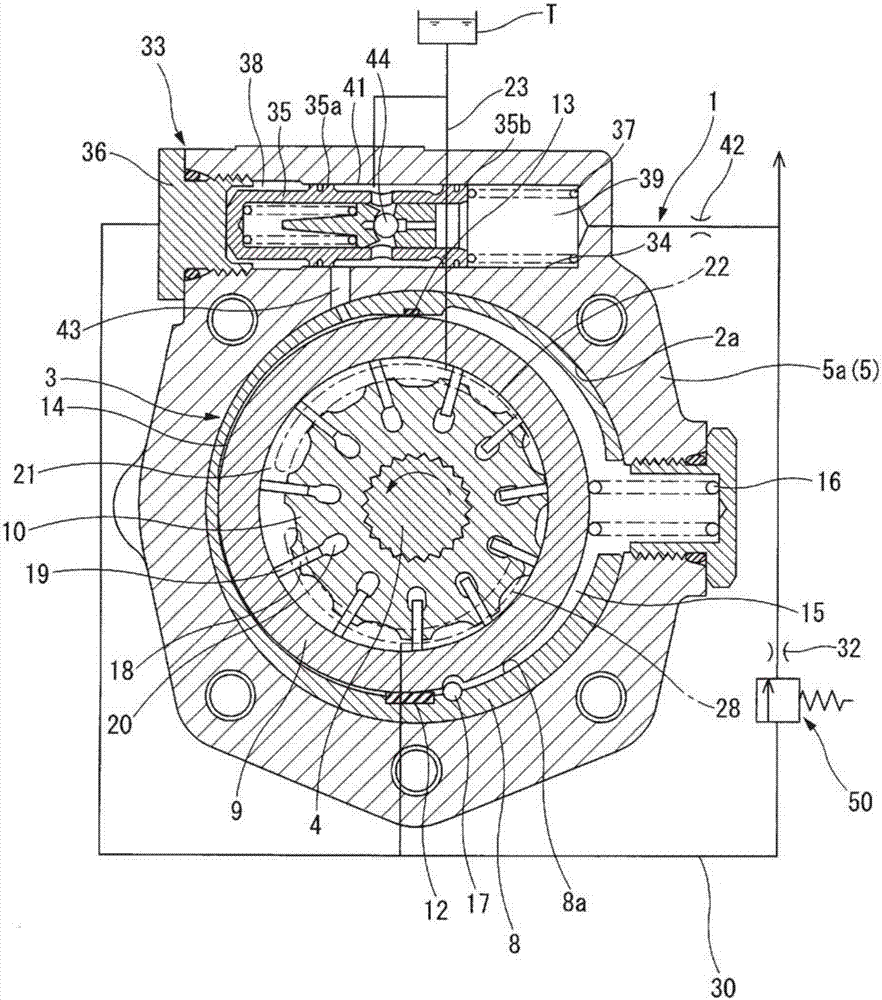

[0104] Figure 11 ~ Figure 13 The second embodiment of the present invention is shown, and the basic structure is the same as that of the first embodiment, but a spring having a nonlinear spring constant (non-linear spring) is used as the coil spring 53 .

[0105] That is, the coil spring 53 of the present embodiment is formed such that at least one of design parameters such as coil diameter, pitch, and wire diameter varies along the axial direction of the coil spring 53, and thus the spring load F is different from that of nature. The relationship of displacement x from the length (hereinafter, simply referred to as “displacement x”) becomes nonlinear.

[0106] also, Figure 11 and Figure 12 is a diagram showing the relationship between the spring load F and the displacement x in an example of the coil spring 53 used in this embodiment, Figure 11 Indicates a so-called 2-stage pitch spring with different pitches on one end side and the other end side, Figure 12 Indicate...

no. 3 approach 〕

[0114] Figure 14 The third embodiment of the present invention is shown, and the basic structure is the same as that of the first embodiment, but the structure of the pump casing 2 is changed. In addition, in the following description, the same code|symbol is attached|subjected to the same structural part as 1st Embodiment, and a specific description is abbreviate|omitted.

[0115] That is, if Figure 14 As shown, the pump casing 2 of this embodiment is composed of a front casing 5 which is a flat first casing and a rear casing 6 which is a bottomed cylindrical second casing. Furthermore, the pump member housing chamber 2 a is formed inside by closing the opening of the rear housing 6 with the inner end surface of the front housing 5 on the rear housing 6 side.

[0116] In addition, as the structure of the pump housing 2 is changed, the fitting ring 8 constituting the pump member 3 is fitted and fixed to the inner peripheral surface of the cylindrical portion 6 b of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com