Warehousing interior moving feeding platform based on Internet control

A networked control, Internet technology, applied in transportation, packaging, conveyors, etc., can solve the problems of low labor intensity, high labor intensity, slow process progress, etc., to ensure work efficiency, low labor intensity, and fast process progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

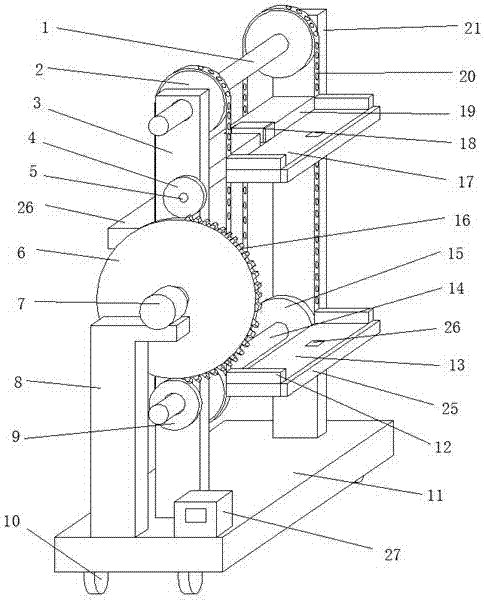

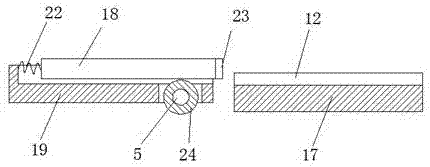

[0027] see Figure 1-2 , a mobile loading platform in a warehouse based on Internet control, including a base 11, a universal wheel 10 is connected to the bottom side of the base 11, and a first vertical plate 2 and a second vertical plate 21 are fixedly connected to the base 11 , and the first vertical plate 2 and the second vertical plate 21 are symmetrical to each other, the lower rotating shaft 14 and the upper rotating shaft 1 are rotatably connected between the first vertical plate 2 and the second vertical plate 21, and the lower rotating shaft 14 A symmetrical lower sprocket 15 is fixedly sleeved on the top, and a symmetrical upper sprocket 2 is fixedly sleeved on the upper rotation 1, and the lower sprocket 15 and the upper sprocket 2 are connected by a chain 20, and the chain The outer side of 20 is fixedly connected with a first article placement board 17, a second article placement board 13 and a third article placement board 26, and a support board 19 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com