Narrow loader multifunctional side-dumping bucket suitable for single track railway tunnel

A single-track railway and loader technology, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems that cannot meet the needs of mobile operation platforms, low power of 40-type loaders, and low slag loading efficiency, so as to improve equipment utilization Efficiency, saving equipment purchase costs, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described with reference to the drawings and specific embodiments:

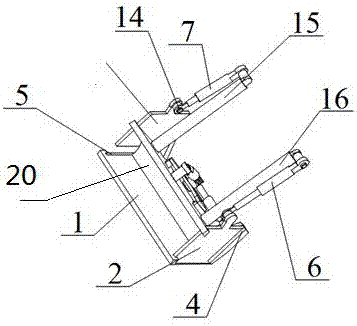

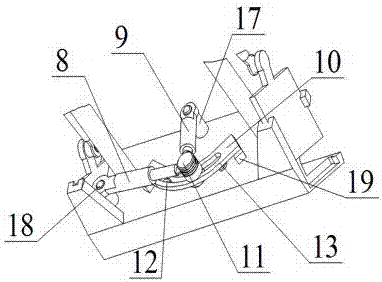

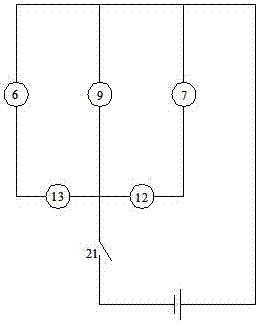

[0013] Such as Figure 1~2 As shown, a narrow body loader multifunctional side dump bucket suitable for single-track railway tunnels. The dump bucket has a bucket bottom plate 1, a bucket top plate 20, a gate I2 as the side wall of the bucket, and a gate Ⅱ3; The bucket bottom plate 1 and the bucket top plate 20 constitute a bucket-shaped structure with left and right ends and an open front end; the gate I2 and gate II3 are arranged at the left and right ends of the bucket-shaped structure, and the bucket-shaped structure The left and right sides of the rear end are respectively provided with a gate rail I4 and a gate rail II5 which slide up and down by the gate I and the gate II; the gate rail I4 is set corresponding to the gate I2; the gate I2 is hinged to the output of the hydraulic cylinder I6 The cylinder tube of the hydraulic cylinder I6 is hinged with the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com