Electronic control light adjusting film based on liquid crystal and dichroic dye and preparing method thereof

A dichroic, light-adjustable film technology, applied in the field of optical polarization, can solve the problem that the anti-peep film cannot be switched, and achieve the effects that the anti-peep performance can be electronically adjusted, the preparation method is simple, and the light transmittance will not be affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

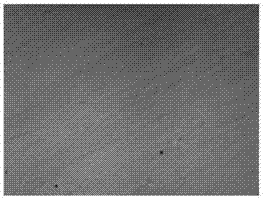

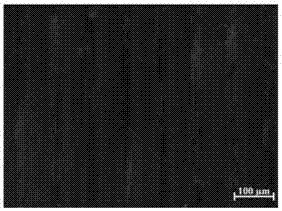

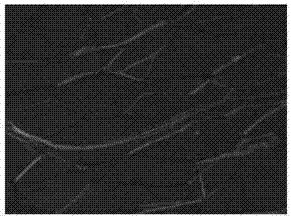

[0043]First, wash the PET substrate coated with ITO film with detergent and warm water, remove the particles, dust and impurities of the PET substrate, then wash it with acetone solution, and spin-coat a layer of PVA orientation on the PET substrate coated with ITO film. agent, cured at high temperature (110°C) for 2 hours, and carried out rubbing orientation. Next, after mixing the photopolymerizable liquid crystal monomer, DD molecules, NLC molecules, photoinitiators, and spacer particles evenly, the mixed solution is sandwiched between two layers of transparent ITO plastic conductive films, and then pressed into a film by pressing rollers. When it is shown in Figure 3(a). Then, as shown in Figure 3(b), by irradiating the film with ultraviolet (UV) light through a mask, the UV light passing through the mask triggers a cross-linking reaction between the photopolymerizable monomer molecules to form a photopolymerizable liquid crystal network , NLC, and DD composite material r...

Embodiment 2

[0046] First, wash the PET substrate coated with ITO film with detergent and warm water, remove the particles, dust and impurities of the PET substrate, then wash it with acetone solution, and spin-coat a layer of PVA orientation on the PET substrate coated with ITO film. agent, cured at high temperature (110°C) for 2 hours, and then carried out rubbing orientation. Next, after mixing the photopolymerizable liquid crystal monomer, DD molecules, N*LC molecules, photoinitiators, and spacer particles evenly, the mixture is sandwiched between two layers of transparent ITO plastic conductive films, and then pressed into a film by pressing rollers , as shown in Figure 4(a). Then, as shown in Figure 4(b), by irradiating the film with ultraviolet (UV) light through a mask, the UV light passing through the mask triggers a cross-linking reaction between the molecules of the photopolymerizable liquid crystal monomer to form a photopolymerizable liquid crystal The network, N*LC, and DD c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com